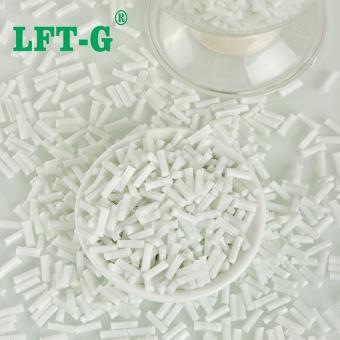

Long glass fiber has high strength, high rigidity, corrosion resistance, harsh environment suitability and low cost. When the resin matrix is impregnated and extruded into pellets ,Also called Long Glass Fiber Polymer it has good mechanical properties.

-

Xiamen LFT-G HDPE filling long glass fiber thermoplasitc reinforced compoundsHDPE-LGF High density polyethylene (HDPE)/ glass fiber (LGF) composites were prepared by twin-screw extrusion mechanism, and the mechanical properties and non-isothermal crystallization behavior of HDPE/LGF composites were studied. The results show that the impact strength of the composite can be improved by MAH-g-POE, and the interface bond between the glass fiber and HDPE is good. The Avrami index (n) of the composite does not change with the cooling rate. Datasheet Application Package Xiamen LFT composite plastic Co.,Ltd Come and find us! We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design and recommendations. 3. Provide technical support such as injection molding and extrusion molding.

- HDPE filling lgf20

- lgf hdpe composite materials

- reinforced hdpe plastic resin

- long glass fiber hdpe

- Thermoplastic hdpe lgf

- hdpe resin compounds

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS material Acrylonitrile-butadiene styrene (ABS) resin is an opaque amorphous thermoplastic engineering plastic with complex two-phase structure. It is composed of styrene, acrylonitrile and butadiene in different proportions. In the 1970s, it began to be recognized by the public and began to be used. In the 1990s, the market demand grew rapidly. At present, it should be used in domestic and foreign markets, especially in construction, home appliances, automobiles and other industries. ABS-LGF Long glass fiber is widely used in engineering plastics. Reinforced ABS composites are made by adding a certain percentage of glass fiber, with the addition of 30% to 50% glass fiber being the most common. So as to improve the mechanical properties of ABS. Such as tensile properties, bending properties, and the corresponding molding shrinkage rate is not reduced, so that the material will not stress cracking. Advantages: 1. Long glass fiber reinforced, glass fiber is a high temperature resistant material, therefore, the heat resistant temperature of reinforced plastic is much higher than before without glass fiber, especially nylon plastics 2. After long glass fiber reinforcement, due to the addition of long glass fiber, the mutual movement between polymer chains of plastic is limited, therefore, the shrinkage rate of reinforced plastics decreases a lot, and the rigidity is greatly improved. 3. After long glass fiber reinforcement, reinforced plastics will not stress crack, at the same time, the anti-impact performance of plastics is improved a lot. 4. After long glass fiber reinforcement, glass fiber is a high strength material, which also greatly improves the strength of plastic, such as: tensile strength, compression strength, bending strength, improve a lot. 5. Long glass fiber reinforced after, due to the addition of glass fiber and other additives, the combustion performance of reinforced plastics decreased a lot, most of the material can not ignite, is a kind of flame retardant material. Datasheet for reference only Processing flow Cases About Xiamen LFT-G Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series(LGF) & Long Carbon Fiber Series(LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 system certification, and the products have obtained lots of national trademarks and patents.

- Modified material lft injection molding

- ABS compounds long glass fiber

- lgf injection mold abs for engineering

- reinforced material abs filling lgf

- ABS-LGF30 thermoplastic resin

- Thermoplastic resin ABS

Tags :

-

Xiamen LFT-G reinforced PBT plastic Long glass fiber polymers high qualityProduct grade: General grade Fiber specification: 20%-60% Product feature: High toughness, Low warpage Product application: Electronic appliances, Machinery parts etc.

- PBT resin high mechanical properties

- Electronic appliances composites

- sample available pbt

- Natural color widely applications

- Fiber filling material compounds

- High toughness industry use

Tags :

-

MXD6 resin Factory price mxd6 Granules PELLETS LGFMXD6 resin granules filling long glass fiber compounds pellets factory price

- MXD6 resin polymer thermoplastic

- MXD6 pellets made in China

- MXD6 polymer imdustrial use good price

- plastic raw material MXD6 GF30 glass fiber

- MXD6 granules reinforced plastic

- plastic MXD6 lgf40 sample available

Tags :

-

Xiamen LFT-G reinforced Polyphthalamide filling long glass fiber injection moldingPPA-LGF PPA, full name polyphthalamide, is a semi-aromatic polyamide with no less than 55% terephthalic acid or phthalic acid as raw material, commonly known as aromatic high temperature nylon. PPA has better mechanical properties and high temperature resistance compared to traditional aliphatic nylon (PA6/PA66) materials. PPA materials have relatively low water absorption, good dimensional stability and good corrosion resistance. Glass fiber reinforced PPA composites have high temperature resistance, high strength and low density, and are considered to be the best resin to replace steel with plastic. Compared with traditional short fiber reinforced pellets, long glass fiber reinforced PPA composites have better physical and mechanical properties. Application Because high-temperature nylon can withstand high strength, high loads, and high temperatures in harsh environments, it is ideal for applications in engine areas (such as engine covers, switches, and connectors) as well as transmission systems (such as bearing cages), air systems (such as exhaust control systems), and air intake units. PPA engineering plastic is a high performance engineering plastic reinforced by fiber with high temperature nylon as the base material. The structure and crystalline characteristics of high-temperature nylon make it have more characteristics and excellent overall performance than nylon 66 and nylon 6 and other engineering plastics: strong rigidity, high hardness, high temperature resistance, good chemical resistance and low water absorption, dimensional accuracy and stability and low warpage, excellent fatigue resistance, in many fields including automotive parts, mechanical parts and electrical and electronic parts used in motor parts It is widely used in many fields including automotive parts, mechanical parts and electrical and electronic parts for motor parts, circuit breakers, etc. Other materials you may wonder About us Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. We will offer you 1. LFT&LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- ppa granules lgf30 GF PPA virgin grade

- best long glass fiber ppa lgf30 granules

- Polymer lgf PPA Virgin pure materials

- pla lgf30 pla granule price good price

- ppa granules lgf30 self factory made

- ppa lft glass fiber fiberglass modified plastic

Tags :

-

Xiamen LFT PLA Polylactic acid compounds long glass fiber thermoplastic resin for engineeringPLA plastic PLA is a non-natural polyester, which is considered as one of the most promising "green plastics" because of its excellent properties such as biocompatibility, biodegradability and high mechanical strength. PLA has good degradability and can be completely degraded by microorganisms. Products made of PLA can be completely degraded to CO2 and water after use, and are non-toxic and non-irritating. PLA has similar mechanical properties to polypropylene, while its gloss, clarity and processability are similar to polystyrene, and its processing temperature is lower than that of polyolefin. PLA can be processed into various packaging materials, fibers and nonwovens through injection molding, extrusion, blistering, blow molding, spinning and other general plastic processing methods, and PLA has been widely used in disposable plastic products. In addition, PLA can also be widely used in chemical, medical, pharmaceutical and 3D printing industries. It is now increasingly recognized that PLA polyesters will play a key role in solving the plastic pollution problem. PLA reinoforced plastic Glass fiber (English name: glass fiber or fiberglass) is an inorganic non-metallic material with excellent performance, the advantages of good insulation, heat resistance, good corrosion resistance, and high mechanical strength. One of the main uses of glass fiber for the reinforcement of composite materials. Long glass fiber generally refers to the length of more than 10mm glass fiber. Long Glass Fiber Reinforced PLA plastic refers to modified PLA composites containing glass fiber lengths of 10 to 25 mm, which are formed into a three-dimensional structure with glass fiber lengths greater than 3.1 mm through injection molding and other processes, and is referred to as Long Glass Fiber PLA, abbreviated as LGFPLA. fiber reinforce thermoplastic). From the material definition, LGFPLA is a kind of LFT. Generally, they are columnar particles of 12mm or 25mm in length and about 3mm in diameter. The pellets of about 12mm length are mainly used for injection molding, while the pellets of about 25mm length are mainly used for compression molding. In these pellets, the glass fiber has the same length as the pellets, and the glass fiber content can vary from 20% to 60%, and the color of the pellets can be color-matched according to customer requirements. LGF & SGF LFT has the following advantages over short fiber reinforced thermoplastic composites: - Longer fiber length, which significantly improves the mechanical properties of the products. - High specific stiffness and specific strength, good impact resistance, especially suitable for automotive parts applications. - Improved creep resistance, good dimensional stability, and high precision of part molding. - Excellent fatigue resistance. - Better stability in high temperature and humid environment. - Fibers can move relatively in the molding mold during the molding process, with little fiber damage. Details Number Color Length Fiber specification Package Sample Port of loading Delivery time PLA-NA-LGF Natural color or as customized 6-25mm 20%-60% 25kg/bag Available Xiamen Port 7-15 days after shipment Lab & factory Xiamen LFT composite plastic Co., Ltd. The rapid development of technology has led to the emergence of LFT carbon fiber composites. Long Fiber (Xiamen) New Material Technology Co., Ltd, provides professional customization service for modified reinforced long carbon fiber composites. Ltd. was founded by a veteran of the thermoplastic reinforced composite industry, focusing on the development and production of (LFT-G.LFRT,LFT) long glass/carbon fiber reinforced thermoplastic engineering plastics. The company produces long carbon fiber composites with the advantages of light weight, high strength, high impact thermal resistance, design and recycleable, green and environmental protection. Compared with traditional materials, it requires lower cost, better corrosion and chemical resistance, and better molding and processing performance, making it the golden material of the 21st century. Long Fiber (Xiamen) New Material Technology Co: Xiamen LFT composite plastic Co., Ltd. is engaged in the development and production of LFRT series of long glass fiber (LGF) and long carbon fiber (LCF) PP, PA6, PA66, PPA, PA12, TPU, PBT, PLA, PET, PPS, PEEK and other engineering plastics. Series of products can be used in the manufacture of home appliances, aerospace, automotive, military, electrical and other parts, such as gears, rollers, pulleys, drums, pump impellers, fan blades, etc. They can also be used in the manufacture of medical equipment, sporting goods, daily necessities and other fields.

- PLA reinforced plastic lgf production pla

- LFT-G PLA injection mold modified materials

- long glass fiber compounds pla resin basic

- PLA pellets of long fiber 30 made in China

- Self owing PLA polymers manufacturer direct sell

- PLA pure pellets virgin grade lft

Tags :

-

Xiamen LFT Reinforced Polyamide 12 Nylon12 Long Glass Fiber High Tensile StrengthWhat is PA12? The scientific name of PA12 is polydodecalactam, also known as nylon 12. The basic raw material for its polymerization is butadiene, which can depend on petrochemicals. It is a semi-crystalline - crystalline thermoplastic material. Its properties are similar to those of PA11, but the crystal structure is different; PA12 is an excellent electrical insulator and, like other polyamides, does not suffer from moisture-related insulating properties. PA12 has a number of improved plasticizing and reinforcing properties. What is PA12-LGF? PA12 filling long glass fiber material is a composite material, adding long glass fiber on the basis of the original nylon12 material, which makes the material have the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, good corrosion resistance, and high mechanical strength. Datasheet for reference Application Suitabel for automotive, sports parts, solar energy, photovoltaic industry and other industries. Details Number Color Length Sample MOQ Package Port of Loading Delivery time PA12-NA-LGF30 Natural color (or customzied) 12mm or so (or customized) Available 25KG 25KG/BAG Xiamen Port 7-15 days after shipment About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Come to contact us for more technical support!

- LFT-G PA12 polyamide12

- thermoplastic pa12 lgf 30

- lft pa12 raw materials lgf white

- Injection mold plastic pa12 gfrp

- xiamen lft price good reinforced pa12

- sample available modified pa12 glass fiber

Tags :

-

LFT Modified Polyamide 66 filled long glass fiber compoundsPA66-LGF Information PA66 is one of the most produced and widely used polyester series products. It has high grain size, excellent tensile properties, bending properties, tensile strength and other material mechanical properties, and its excellent ultra-low temperature characteristics and organic chemical properties. It is a class of rubber products with wide range of application, stable characteristics, good mechanical properties, high quality insulation, low density, easy processing and molding, self-extinguishing, and good wear resistance. Therefore, it is widely used in vehicles, electronic and electrical, chemical materials, industrial equipment, instrument panels, construction projects and other industries. However, it has high water absorption, poor alkali resistance, dry ultra-low temperature impact, low compressive strength and easy to deform after absorbing moisture, which affects the reliability of goods specifications. People have improved PA66 in a variety of ways, adding PA66 chemical fiber is one of them. After adding glass fiber, its impact force, heat deformation, material mechanical properties, molding processability and acid resistance are significantly improved. Glass fiber is a class of functional raw materials with high quality characteristics. This utility model has the advantages of low cost, non-combustibility, high temperature resistance, acid resistance, high tensile strength, high impact compressive strength, low tensile strength, high quality insulation properties, high quality insulation properties, etc. It is usually used as a raw material to improve organic chemical polymers or functional materials and composites. The most important hazard of proportional limits to raw materials is mechanical properties. The material mechanical properties of modified PA66 are also related to the composition of glass fibers. The tensile strength, bending strength and impact compression strength of PA66 increase with the glass fiber composition after the addition of PA66 chemical fibers. The tensile and flexural strengths of the managed system increased linearly, but the glass fiber composition was 30%. The trend of increasing tensile and flexural strengths showed some improvement. The results show that PA66 can produce a reasonable page layer, which can reasonably transfer the ground stress between the matrix and page, and thus improve the compressive strength of the matrix. PA66-LGF TDS The datasheet was tested by Xiamen LFT, for your reference only. PA66-LGF Application Suitable for many fileds, other application you can ask for our technical advice. Details Number Color Length Sample MOQ Port of Loading Delivery time Payment terms PA66-NA-LGF Original color (can be customized) 12mm (can be customized) Available 25kg Xiamen Port 3-45 days after shipment Discussed Xiamen LFT composite plastic Co., Ltd Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 &16949 system certification, and the products have obtained lots of national trademarks and patents. We will offer you: 1. LFT&LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.

- Low warpage electronic appliance

- self owing pa66 pellets thermoplastic resin

- high strength and high toughness reinforced pa66 pellets

- best long glass fiber pa66 lgf30 granules

- PA66 6 twin screw lgf pellets

- Long Fiber PA66 granules Application

Tags :

-

LFT Polyamide 6 Nylon 6 Reinforced Long Glass Fiber Orginal Color for automotive partsWhat is PA6 plastic? polyamide (PA), usually called Nylon, is a hetero-chain polymer containing amide group (-NHCo -) in the main chain. It can be divided into aliphatic group and aromatic group. It is the earliest developed and the most used thermoplastic engineering material. Polyamide main chain contains many repeated amide group, used as a plastic called nylon, used as a synthetic fiber called nylon. A variety of different polyamides can be prepared according to the number of carbon atoms contained in binary amines and dibasic acids or amino acids. At present, there are dozens of polyamides, among which polyamide-6, polyamide-66 and polyamide-610 are the most widely used. Polyamide-6 is an aliphatic polyamide, with light weight, strong strength, wear resistance, weak acid and alkali resistance and some organic solvents, easy molding and processing and other excellent properties, widely used in fiber, engineering plastics and thin films and other fields, but PA6 molecular chain segment contains strong polarity amide groups, easy to form hydrogen bonds with water molecules, The product has the disadvantages of large water absorption, poor dimensional stability, low impact strength in dry state and low temperature, strong acid and alkali resistance. Advantages of nylon 6: High mechanical strength, good toughness, high tensile and compressive strength. Outstanding fatigue resistance, the parts after repeated bending can still maintain the original mechanical strength. High softening point, heat resistant. Smooth surface, small friction coefficient, wear-resistant. Corrosion resistance, very resistant to alkali and most salts, also resistant to weak acids, oil, gasoline, aromatic compounds and general solvents, aromatic compounds are inert, but not resistant to strong acids and oxidants. It can resist the corrosion of gasoline, oil, fat, alcohol, alkaline and so on, and has good anti-aging ability. It is self-extinguishing, non-toxic, odorless, good weather resistance, inert to biological erosion, and has good antibacterial and mildew resistance. Has excellent electrical performance, good electrical insulation, nylon volume resistance is high, high breakdown voltage resistance, in dry environment, can work frequency insulation material, even in high humidity environment still has good electrical insulation. Light weight, easy dyeing, easy forming, because of low melting viscosity, can flow quickly. Disadvantages of Nylon 6: Easy to absorb water, water absorption, saturated water can reach more than 3%. Poor light resistance, in the long-term high temperature environment will oxidize with oxygen in the air, the color turns brown at the beginning, and the subsequent surface is broken and cracked. Injection molding technology requirements more strict, the existence of trace moisture will cause great damage to the quality of molding; The dimensional stability of the product is difficult to control because of thermal expansion. The existence of sharp Angle in the product will lead to stress concentration and reduce the mechanical strength; If the wall thickness is not uniform, it will lead to the distortion and deformation of the parts. High precision of equipment is required in post-processing. Will absorb water, alcohol and swelling, not resistant to strong acid and oxidant, can not be used as acid-resistant materials. Why filling Long Glass Fiber? PA6 has excellent properties such as light weight, strong strength, abrasion resistance, weak acid and alkali resistance and some organic solvents, and easy molding and processing. It is widely used in the fields of fibers, engineering plastics and films. However, the molecular chain segment of PA6 contains highly polar amide groups, which are easy to form hydrogen bonds with water molecules. The product has the disadvantages of large water absorption, poor dimensional stability, low impact strength in dry state and low temperature, strong acid and alkali resistance. With the development of science and technology and the improvement of life quality, the defects in some properties of traditional PA6 materials have limited its development in some fields. In order to improve the performance of PA6 and expand its application field, PA6 should be modified. Filling enhancement modification is a common method for physical modification of PA6. It refers to the modification of PA6 by adding fillers such as glass fiber and carbon fiber into the matrix to significantly improve the mechanical properties, flame retardant properties, thermal conductivity and dimensional stability of the material. What is application of PA6-LGF? Modified section of 30% long glass fiber reinforced PA6 is the ideal material for processing power tool shell, power tool parts, engineering machinery parts and automobile parts. Its mechanical properties, dimensional stability, heat resistance and aging resistance have been significantly improved. The fatigue resistance strength is 2.5 times that of unenha...

- Polyamide 6 composite properties

- lgf thermoplastic resin good price

- High impact PA6 instead metal plastic

- injection molding plastic gf30 filter

- pa6 filling long glass fiber customized

- Advanced plastic lightweight compounds

Tags :

-

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinPP material Polypropylene, PP for short, is a polymer of propylene by adding polymerization. White waxy material, transparent and light in appearance. Polypropylene is a thermoplastic synthetic resin with excellent properties. It is a colorless translucent thermoplastic lightweight general plastic with chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear-resisting machining properties. PP-LGF material PP plus glass fiber is by adding glass fiber reinforced PP material, due to the addition of glass fiber, limited the mutual movement between polymer chains of PP plastic, therefore, the shrinkage rate of glass fiber reinforced PP (PP plus glass fiber) decreases, rigidity, impact resistance, tensile strength, compression strength, bending strength and flame retardant are improved. The mechanical properties of PP plus glass fiber specifically, tensile strength reached 65MPa--90MPa, bending strength reached 70MPa--20MPa, bending modulus reached 3000MPa--4500MPa, such mechanical strength can be completely comparable with ABS and enhanced ABS products, and more heat resistant. Generally, the heat resistance temperature of ABS and reinforced ABS is between 80℃--98℃, and the heat resistance temperature of glass fiber reinforced PP material can reach 135℃--145℃, and even 150 degrees can withstand more than 1000 hours. Compared with SGF(Short Glass Fiber) TDS for reference only Application of PP-Long glass fiber PP filling long glass fiber material, can be used to make refrigerators, air conditioning and other refrigeration machines in the axial flow fan and fan. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high mechanical performance requirements, used for rice cooker base and handle, electronic microwave oven and other places with high temperature resistance requirements, generally speaking, most glass fiber reinforced PP material is used in the structural parts of the product, is a kind of structural engineering materials. Cases Washing machine parts Automobile front end parts Scooter parts Frequently asked questions 1. Does long glass fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. 2. After long glass fiber reinforced, glass fiber can enter the surface of the plastic product during injection molding process, so that the surface of the product become rough and floating fiber. How to make the surface of the material smoothly? A. During injection molding process need to ensure that the plastic particles are well plasticized and dispersed, also ensure that the drying of plastic particles have no moisture removal, mold temperature adjustment to the appropriate temperature, mold surface is polished in place. 3. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products,

- long fibre reinforced thermoplastics

- long fiber compounds pp

- pp lgf40

- long glass fiber polypropylene

- long fiber composite PP granules

- PP LFT Compounds polymers

Tags :

-

Xiamen LFT-G reinforced PBT plastic Long glass fiber polymers high qualityProduct grade: General grade Fiber specification: 20%-60% Product feature: High toughness, Low warpage Product application: Electronic appliances, Machinery parts etc.view more

-

Xiamen LFT-G ABS Acrylonitrile Butadiene Styrene long glass fiber reinforced for industrial useWhat is ABS? 1. ABS plastic is a thermoplastic polymer structural material, mainly through propylene, butadiene and other chemical substances synthetic polymer material, also known as ABS resin, because of its good heat resistance, impact resistance, processing, so the use of a wide range. 2. Because ABS plastic is very hard, it has strong impact resistance, scratch resistance, dimensional stability and other properties, and has the characteristics of moisture, corrosion resistance, easy processing, etc., it is an ideal material. 3. ABS material also has good light transmission, compared with the same transparency of acrylic, although it has better toughness, the price is relatively high, and the color is not more than the color of acrylic, generally beige, black, transparent three colors. 4. ABS material is also very environmentally friendly, due to the use of environmentally friendly chemicals, so non-toxic and odorless, but also with electrical insulation, is a very safe material. 5. ABS material is easy to deform in a high temperature environment, and the deformation temperature is 93-118 degrees Celsius, but it performs very well in a low temperature environment, so it is also a high temperature resistant material. What Are the Advantages of ABS Plastics? ABS has some major advantages as a general-purpose engineering material. Below is a brief list of some of ABS plastic's advantages: ABS is inexpensive and plentiful, coming in many colors, material characteristics, and forms (pellets, tubes, bar, filament, etc.). ABS is sturdy, lightweight, and ductile, being easily machined but retaining good resistance to chemicals, impacts, and abrasions. ABS is more heat-resistant than other thermoplastics in its weight class and can withstand multiple cycles of heating/cooling, making it a fully recyclable plastic. ABS can achieve a highly attractive finish and is readily paintable. ABS has low heat and electrical conductivity. Compared with PLA Acrylonitrile Butadiene Styrene (ABS) was first patented in 1948 and commercialized in 1954 by the Borg-Warner Corporation. It is an amorphous thermoplastic polymer where the molecular structure is disordered. ABS is commonly manufactured via the polymerization of styrene and acrylonitrile. ABS is a tougher plastic than PLA. It can be used for applications that require significant strength and impact resistance. The Advantages of ABS Compared to PLA? ABS has a higher glass transition temperature than PLA. ABS is generally tougher than PLA. It can withstand impact loads and has better abrasion resistance. PLA vs. ABS: Applications Comparison PLA is not widely used for typical consumer and industrial applications. It is mostly used for 3D printing in hobbyist applications or prototyping but has found some applications in the biomedical industry. ABS, on the other hand, is used as an engineering plastic across almost every industry. It is preferred for applications requiring toughness and impact resistance. PLA vs. ABS: Part Accuracy Comparison PLA is a very easy material to 3D print and it produces parts that are dimensionally stable. ABS, on the other hand, tends to warp easily during printing. PLA vs. ABS: Speed Comparison Both PLA and ABS can print at rates from 45 to 60 mm/s. PLA vs. ABS: Surface Comparison 3D-printed PLA and ABS have the common FDM (Fused Deposition Modeling) surface finish with visible layer lines. However, ABS can be vapor smoothed with solvents like acetone while PLA must be hand sanded for optimal surface finish. The vapor smoothing process melts the surface, giving it a smooth and homogeneous finish. PLA vs. ABS: Heat Resistance Comparison PLA has poor heat resistance when compared to ABS. PLA will begin to soften at 60 °C whereas ABS does not begin to soften until 105 °C. PLA vs. ABS: Biodegradability Comparison PLA is a bioplastic and biodegradable under the correct conditions. Unfortunately, these conditions are only present in industrial composting facilities. The required conditions include high temperatures and exposure to specific microbial environments. PLA can take up to 80 years to fully decompose in nature. ABS, on the other hand, is not biodegradable and can take hundreds of years to fully decompose. PLA vs. ABS: Toxicity Comparison PLA is generally recognized as safe and non-toxic after printing. During printing, PLA releases VOCs (Volatile Organic Compounds). As such, it is not recommended to print PLA in an unventilated area. However, these VOCs are low in concentration and ventilation is just an added precaution. ABS contains no known carcinogens and has no adverse health effects once printed. However, ABS also releases dangerous VOCs and nanoparticles (UPFs) during printing, far more than is the case with PLA. As such, it is advised to cover printers with a hood and to utilize a ventilation duct. PLA vs. ABS: Cost Comparison PLA and ABS are among the lowest-cost materials used in 3D printing. Both can be pu...

- ABS can be recycled plastic made in China

- thermoplastic resin raw materials

- abs for whole sell good price fiberglass

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文