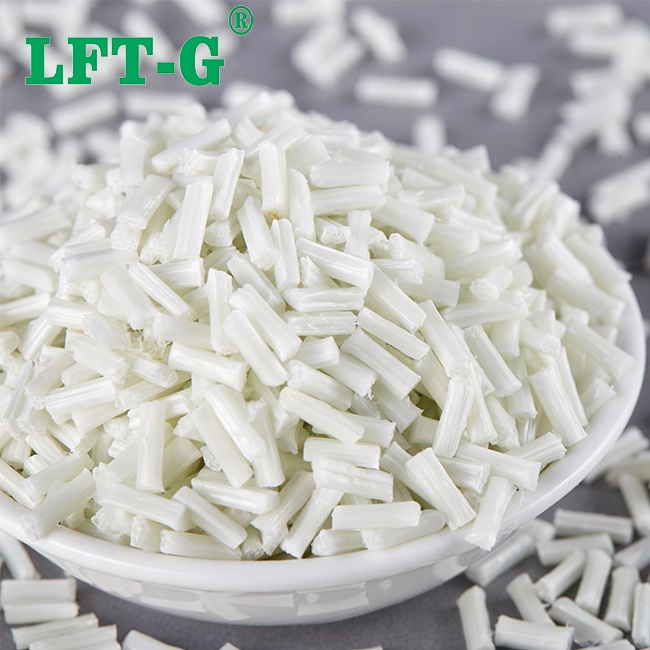

TPU LGF30 Long Fiber Thermoplastic TPU LGF Density And TDS

Form: Length about 12mm, High strength, High toughness

Advantage: More than 20 years experience product in fiber reinforced plastic .

LFT-G is a team led by professionals who have been in the plastics industry for nearly 20 years. We specialize in design, research and development, tailor-made long glass fiber for customers; long carbon fiber; comprehensive long glass fiber & long carbon fiber; special Fiber composite. Materials can be widely used in aerospace, automotive, military; home appliances;

√ The first lightweight third row freestanding seat back √ Solution helps new cars lose 30% weight and save 15% cost over their predecessor Lightweight parts have been successfully applied and applied to the new 2021 cars. The new model, due to go on sale in the second half of this year, has managed to reduce body weight with a lightweight component on the back of the third-row chair. The third-row back of the previous generation of cars was made up of 15 different steel components, and the body was very heavy. So hopefully the 2021 third row seats will meet all performance criteria while being lighter and more cost competitive. "Being lighter does not necessarily mean being more expensive," the researchers said. Compared with the previous generation model, during the research and development of the new model, we not only achieved a 30% reduction in the weight of the third row seat, but also saved 15% of the cost. These goals are achieved because we have many great partners." The resin parts of traditional car seats contain metal reinforcement, which increases the cost of the process. The hope is to obtain a whole injection parts without complex, expensive processing. To meet the requirements, an exclusive 35% fiberglass reinforced, impact-resistant modified polyamide PA6 product was used along with its proprietary computer simulation (CAE) tool that can be used in multiple stages of development. Basf's proprietary computer simulation (CAE) tools "I classify the third row seat design of the 2021 Toyota Senna as an enabling technology," said the developer. It is the first all-injection molded seat back of its kind to be designed without any inserts, and one of the design challenges was to ensure the seat had high elongation and impact resistance to meet crash-avoidance requirements. "At the same time, we focused on the strength and stiffness of the seats, because the third row also supports the floor." Contact us, we will offer you the best materials with the best price.

Nylon 12 (PA12) is a kind of polyamide engineering plastics with excellent properties. With rich petroleum by-product butadiene as the main raw material, low production cost, high economic effect, has been widely used in various fields. Modified nylon 12 is made of nylon 12 resin and quantitative filler, color powder, additives and other components blend, after extrusion, granulation and other processes to obtain a thermoplastic with different properties. LFT-G Chemical modified nylon 12 series products are suitable for extrusion, injection molding and other processing technology, can meet the diversified and customized needs of customers, suitable for automobile, electronic appliances, communications, electric power, medical, sports equipment and other fields. Product line includes: Long glass fiber reinforced PA12, Long carbon fiber reinforced PA12 Long glass fiber reinforced PA12 series LFT-G® long glass fiber reinforced PA12 series is divided into LGF20, LGF30, LGF40 and other specifications according to the long glass fiber filling volume, with the long glass fiber content ranging from 20%-60%. Applications: electronic appliances, sports equipment, quick connector, connector, sanitary ware, shell, bracket, etc. Long carbon fiber reinforced PA12 series LFT-G® long carbon Fiber reinforced PA12 series is divided into LCF30, LCF40, LCF50 specifications according to the filling amount of carbon fiber (20%-60%). It has good strength, dimensional stability, conductivity, impact resistance, etc. Applications: electronic appliances, sports equipment, quick connector, connector, sanitary ware, shell, bracket, etc.

Sales of new energy vehicles increased significantly Make the concept of "car lightweight" It's hot again. A variety of modified plastics, composite materials and light alloy materials are increasingly mature, not only in the traditional automobile engine around, but also in the power battery of new energy vehicles, there are a variety of plastic applications. But these plastics do not perform well on the safety issue of flame retardancy. Flame retardant and its related industries along with "automobile lightweight" become the hot spot of the automobile industry. Development direction of flame retardant plastics for auto parts At present, the common types of flame retardant materials used in automotive parts are PP, PA, PU, PC, ABS materials, as well as a variety of modified materials and composite materials composed of them. Compared with traditional fuel vehicles, new energy vehicles have added battery modules, charging piles and charging guns and other components. ➡️ The amount of engineering plastics used for battery pack module of a single new energy vehicle is about 30kg. The plastic shell of new energy vehicle mainly uses modified PP, modified PPS, PPO and other high temperature resistant plastics. ➡️ Charging piles require engineering plastics due to high usage standards and harsh operating environment. Each charging pile needs about 6kg engineering plastics. At present, PBT, PA and PC are commonly used. When preparing flame retardant plastics, most of them will increase their limiting oxygen index LOI to about 25-35%, so as to effectively improve the overall safety index of vehicles. In addition, with the current combination of electrification and carbon neutrality, plastics and various flame retardants containing halogens will be more restricted. Therefore, the future development direction of flame retardant plastics, in addition to the need for sufficient mechanical properties to meet the lightweight demand, in electric vehicles and other fields will also need materials to pay attention to the electrical, processing, environmental protection requirements Flame retardants will develop towards the direction of halogen-free and high performance, while the research focus of high performance flame retardants will develop towards the direction of complex co-effect flame retardants, halogen-free flame retardants, expansion flame retardants, superrefinement, nano technology, high efficiency surface chemical modification technology and multi-functional technology. Application of flame retardant materials in automobile parts At present, the flame-retardant plastics mainly used are PP, PU, ABS and PC. According to the special needs of automobile parts, composites (alloying), PA, PBT and PMMA are also used accordingly. Flame retardant PP PP is the largest amount of automotive plastic polymer material, has excellent chemical corrosion resistance, and the processing process is simple, low cost. Widely used in automobile instrument panel, battery pac...

Long Glass Fiber reinforced polypropylene plastic refers to the modified polypropylene composite material which contains the glass fiber length between 10 and 25mm. After injection molding and other processes, the three-dimensional structure is formed. It is also called Long Glass Fiber polypropylene, or LGFPP. There are also many materials at home and abroad referred to Long fiber reinforced thermoplastic as LFT, that is, the abbreviation of long-fiber reinforce thermoplastic. From the material definition, LGFPP belongs to a kind of LFT. Material characteristics Microstructure determines macro performance, so 10~25mm long glass fiber reinforced plastics (LGFPP) compared with ordinary 4~7mm short glass fiber reinforced plastics (GFPP) has higher strength, stiffness, toughness, dimensional stability, low warpage. In addition, long glass fiber reinforced polypropylene has better creep resistance than short glass fiber reinforced polypropylene even if it is subjected to 100℃. On the injection molding product, the long glass fiber interleaved into a three-dimensional network structure, even after the polypropylene substrate is burned, the long glass fiber network still forms a certain strength of the glass fiber skeleton, while the short glass fiber after burning generally into a non-strength fiber skeleton. This is mainly because the ratio of length to diameter of reinforced fiber determines the reinforcement effect. The critical length to diameter ratio is L/D. The packing and short glass fiber with the critical length to diameter ratio less than 100 have no reinforcement effect, while the long glass fiber with the critical length to diameter ratio less than 100 has the reinforcement effect. Compared with metal materials and thermosetting composites, the density of long glass fiber plastics is low, and the weight of the same parts can be reduced by 20~50%. Long glass fiber plastics can provide designers with greater design flexibility, such as forming parts with complex shapes, integrating the number of parts used, saving the cost of the mold (generally the cost of long glass fiber plastic injection mold is about 20% of the cost of metal stamping mold). Reduce energy consumption (production energy consumption of long glass fiber plastics is only 60~80% of steel products, 35~50% of aluminum products), simplify the assembly process. What are the typical application parts of automobile Based on the application advantages of long glass fiber material, it has been applied more and more widely in automobiles. In the mainstream models and new models, we have seen more and more of the following parts are made of long glass fiber reinforced polypropylene material. Long fiber reinforced polypropylene is used in car dashboard body frame, battery bracket, front end module, control box, seat support frame, spare placenta, fender, chassis cover plate, noise partition, rear door frame, etc. The following, a few long glass fiber plastic typical application parts a...

lft-g® ‘s team has a combined 20 years of composites knowledge, our design, material, and process engineers are always accessible to answer your questions and as our partner will be there to support you throughout your entire product life cycle.

Share with you some of our factory's new product development, participation in industry forums, training, exhibitions and sharing with examples of high-end forums sponsored by the industry.

2024

NPE 2024 The Plastic Show Date: May 6-10, 2024 Opening Hours: 09:00-17:00 Venue: the Orange County Convention Center (OCCC) in Orlando, Florida, USA. Booth: S19193C--South Hall Level 1 Exhibition consultant: Cason (+86) 13950095707 Attracting attendees from over 110 countries, NPE® is the largest plastics trade show in the Americas and your single source destination for every segment of the supply chain. With 2,000+ exhibitors spanning 1.1 million net square feet of expo space, you will have the opportunity to witness state-of-the-art mold components, extruders, auxiliary equipment, automation technology alongside cutting-edge materials science and additive manufacturing. Plus, NPE2024 includes over 10,000 square feet of recycling demonstrations featuring equipment being run worldwide. If you’re looking to meet suppliers and manufactures you won’t find at any other event, NPE2024 is made for you. Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. Sincerely invite you to participate the NPE and visit our booth. We will show you high performance and popular materials there. Looking forward to meet you.

read more2024

The company carefully planned a wonderful New Year party to thank everyone for their hard work over the past year. The activities include elite team improvement training, sumptuous dinner, award ceremony, lottery and Women's Day activities. Let us look back on this unforgettable day together. Elite team improvement trainging In order to enable the team to improve their capabilities in the new year, the company arranged training sessions. Through the explanations of expert lecturers, colleagues gained a deeper understanding of corporate culture, industry trends, company strategies, sales skills, job skills, etc., which provided strong support for their work in the new year. Sumptuous dinner The dinner kicked off. Company leaders and all employees gathered together to share delicious food and talk about the future. The atmosphere at the dinner was warm, with everyone blessing each other and looking forward to a bright future. Award ceremony During this period, company leaders presented awards to employees with outstanding performance at work. These awards are not only recognition of everyone's hard work in the past year, but also motivation for everyone's future work. Let us congratulate these award-winning colleagues and look forward to achieving greater success in the new year. Lottery In order to let all employees share the joy, the company prepared generous prizes. The atmosphere at the scene reached a climax, with everyone actively participating and laughing constantly. Women's Day activities In order to thank female colleagues for their hard work at work, the company held a celebration event to send special gifts and sincere blessings to female colleagues. End With the care and support of the company's leaders, this event was a complete success. This is an annual "family event" organized by the company, which boosts morale, creates happy energy, creates a joyful atmosphere, deepens internal communication, promotes strategic sharing, enhances goal recognition, and sets new goals to prepare for the new year's work. Sound the overture. Let us work together to create a brilliant 2024!

read more2024

CHINAPLAS 2024 The 36th International Exhibition on Plastics and Rubber Industries Date: 2024.4.23-26 Opening Hours: 09:30-17:30 Venue: National Exhibition and Convention Center,Hongqiao,Shanghai(NECC),PR China Booth NO.: Hall 7.2--B21(Close to Gate 1) Free VIP tickets are now available! Admission is free: the original ticket price is 80 Chinese yuan (about $11). If you would like to have a face-to-face technical communication with Xiamen LFT, please contact us to obtain a free ticket. Deadline: 15 March 2024, 17:00 (GMT+8:00) Contact: Wallis Wan sale02@lfrtplastic.com

read more