Long carbon fiber is a new material with high strength and high modulus and excellent mechanical properties. It is a microcrystalline graphite material obtained by carbonization and graphitization of organic fibers. Its specific gravity is less than 1/4 of steel, and its strength is higher than that of steel. Corrosion resistant, high modulus, no melting. And a variety of resin substrates after impregnation extrusion molding into pellets, long carbon fiber polymer. Can be used for direct molding products. In recent years, it has been widely used in aerospace, mechanical and electronic chemicals.

-

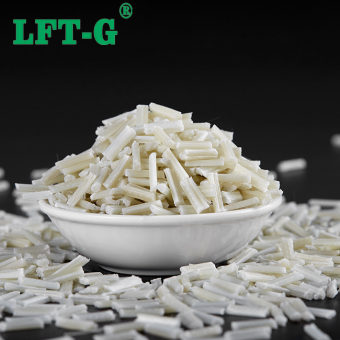

LFT-G Homo Polypropylene filling Long carbon fiber 20%-60% injection molding high toughness and strength 12mmPP-LCF reinforced plastic With the development of new energy vehicles and in the trend of automotive lightweighting, carbon fiber reinforced materials are more and more widely used in the automotive field, especially carbon fiber reinforced PP materials. The modified PP reinforced by carbon fiber has a series of advantages such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat and impact resistance, corrosion resistance, good vibration absorption, etc., which can be applied to automotive parts such as sub-instrument assembly. While composites may be more expensive to manufacture than standard metals or non-reinforced plastics, their extended life, higher fuel efficiency and lower manufacturing costs can offset the initial cost over the life of the product, making carbon fiber a viable alternative. Advanced composites outperform metals: Compared to traditional materials such as aluminum and metals, carbon fiber composites offer a high-performance solution for producing lighter weight, stronger structural components. Application for reference Projects our customers used to test The difference between LCF and SCF Short fiber-reinforced thermoplastic materials: fiber retention length <1M. Long fiber-reinforced thermoplastic materials: fiber retention length 6~25MM. The longer the length of carbon fiber retained, the better the mechanical properties. Uneven distribution of fibers in the cross section of short fiber particles. The arrangement of the particle cross-section of long fibers is orderly, so the overall structure is strong, so the hardness is definitely better than that of short fiber discs. Other materials you may wonder PA6-LCF PA66-LCF PEEK-LCF About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Contact us if you need LFT-G® PP LCF material

- PP virgin grade cfrp

- reinforced pp long carbon fiber

- pp compounds cf

- thermoplastic pp lft-g

- black pp polymer pellets

- pp high toughness carbon fiber

Tags :

-

LFT-G brand high performance PLA materials filling long carbon fiber compounds high toughness 12mm lengthPLA materials Polylactic acid (PLA), also known as polypropyleneglycolate, raw materials from corn, potatoes and other starch-containing food crops or crop straw cellulose, by modern biological fermentation technology to produce high-purity small molecules of lactic acid contained in the human body, and then the lactic acid prepared into a cyclic dimer propyleneglycolate, and then the propyleneglycolate ring-opening polymerization to produce polylactic acid and then after a special polymerization reaction The lactic acid is then prepared into a cyclic dimer, which is then ring-opened and polymerized to produce polylactic acid. Because of its reliable biosafety, biodegradability, environmental friendliness, good mechanical properties and easy processing, PLA has a broad application prospect in biomedical polymers, textile industry, plastic industry, furniture industry, agricultural land film and packaging industry, etc. The raw materials of PLA are sufficient and renewable, and the products made from it can be composted directly after use, and eventually can be completely degraded to CO2 and H2O. PLA is an environmentally friendly, green and sustainable polymer material. PLA-LCF materials Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. It's widespread use in aerospace and other advanced industries makes it a "high-tech" perception of consumers. LCF & SCF Long carbon fiber and short carbon fiber mainly refer to the application length of carbon fiber materials, there is no strict fixed distinction between the two, generally between a few millimeters to a few centimeters, the more common specifications are 6mm, 12mm, 20mm, 30mm, 50mm. the shorter the length the easier it is to uniformly and non-directionally distributed in the resin matrix. Therefore, the mechanical properties of short carbon fibers are far less than those of long carbon fiber reinforced thermoplastic composites. LCF & Metal Product processing Details Number Length Color Sample Packge MOQ Port of Loading Delivery time PLA-NA-LCF30 12mm (also can be customized) Natural color (also can be customized) Available 25kg/bag 25kg Xiamen Port 7-15 days after shipment Q & A 1. How does thermoplastic carbon fiber composite material achieve low cost and environmental protection? Thermoplastic carbon fiber composites are used to make parts for high-end machinery. They have excellent machinability, vacuum forming, stamping mold plasticity, and bending processability. For example, Teijin has been able to add a recycling process to the process according to special needs, and to shred and mold the corners of thermoplastic carbon fiber composites after stamping to make recycled materials for making small products or for molding nuts and studs on carbon fiber prototypes. This method can greatly reduce the loss of raw materials, improve the efficiency of the use of thermoplastic carbon fiber composite materials, reduce the overall cost, and thus achieve the purpose of environmental protection. Thermoplastic carbon fiber products production process In addition, compared with thermoset carbon fiber composites, thermoplastic carbon fiber composites can shorten the molding cycle time due to its special process characteristics, which can further reduce the production cost in terms of production efficiency. 2. Is thermoplastic carbon fiber composite material only suitable for injection molding? From the process point of view, injection molding has a higher degree of automation compared with molding, and the raw material is not in contact with the outside world, so the product appearance quality is guaranteed, and there are no black spots, impurities, uneven colors, etc. The mechanical properties, dimensional stability and precision of the product are relatively higher. At present, Japan Toray, these carbon fiber giants in the application of carbon fiber reinforced thermoplastic composites, the main use of injection molding method, and this method is suitable for the production of complex-shaped parts and mass production. It should be noted, however, that thermoplastic carbon fiber composites using injection molding must be reinforced with short-cut or powdered carbon fibers, and this process is not applicable to continuous carbon fiber reinforced thermoplastic composites. Compared to injection molding equipment, compression molding equipment and its mold structure are relatively simple and less expensive to manufacture. The molding equipment can be used for both thermosetting and thermoplastic resins, and in the molding of ...

- PLA composite plastic

- PLA plastic resin virgin carbon fiber

- pla modified plastic for car parts

- PLA-LCF polymer pellets

- carbon fiber reinforced plastics granules

- pla engineering materials carbon fiber

Tags :

-

LFT-G PPS Polyphenylene sulfide compounds long glass fiber virgin resin original color high rigidity

- PPS lgf pure grade resin pellets

- long fiber composite pps materials

- pps filling fiber reinforced

- modified pps filling long glass fiber

- injection molding pps instead metal

- LFT-G pps high performance

Tags :

-

lft-g PA66 compounds filled long carbon fiber 30% Polyamide66 reinforced plastic high rigidity and tensile strengthPA66 plastic Nylon is the common name for polyamide (PA), a generic term for thermoplastic resins containing repeating amide groups on the main chain of the molecule, including aliphatic polyamides, aliphatic-aromatic polyamides and aromatic polyamides. As the top five engineering plastics, nylon has an extremely wide range of industrial applications, mainly in the fields of automotive parts, mechanical parts, electronics and electrical appliances, cosmetics, adhesives and packaging materials. Among them, the largest production and most widely used are aliphatic polyamides, mainly nylon 66 and nylon 6. Nylon 66 (PA66) is a class of polyamides made by condensation of adipic acid and hexanediamine. Advantages: high strength, corrosion resistance, good wear resistance, and has excellent properties such as self-lubricating, flame retardant, non-toxic and environmental protection. Disadvantages: poor heat resistance and acid resistance, low impact strength in dry state and low temperature, large water absorption rate affects the dimensional stability and electrical properties of the products. PA66 filling Long Carbon Fiber (LCF) Carbon fiber is an inorganic polymer material with carbon content higher than 90% obtained by carbonization and graphitization of organic fibers. Advantages: light mass, high strength, high modulus, high temperature resistance, wear resistance, corrosion resistance, fatigue resistance, electrical and thermal conductivity, etc. Disadvantages: high cost, relatively difficult to infiltrate, poor transparency, etc. Carbon fiber composites are very useful structural materials, which are not only light and high temperature resistant, but also have high tensile strength and elastic modulus, and are indispensable materials for the manufacture of spacecraft, rockets, missiles, high-speed aircraft and large passenger aircraft. In transportation, chemical industry, metallurgy, construction and other industrial sectors, as well as sports equipment and other aspects have a wide range of applications. Datasheet for reference We can provide long carbon fiber filling from 20% to 60%. Different fiber specifications have different characteristics. Application More products you can contact us for technical supports. LCF VS SGF As the fiber length increases, the stiffness and strength of the composite material gradually increases, but the dimensional complexity gradually decreases and the productivity gradually decreases. Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher toughness than short fiber, and the tensile strength is increased by 0.5-1 times. Product details Number Length Color Sample Package MOQ Port of Loading Delivery time PA66-NA-LCF40 12mm (can be customized) Natural color (can be customized) Available 20kg/bag 1 ton Xiamen Port 7-15 days after shipment Xiamen LFT in the exhibitions We will offer you 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.

- Long carbon fiber Reinforced Polypropylene for electrial accessories

- self owing pp pellets

- high toughness plastic pp cf CFRP

- LFT-G PP resin modified best price

- PP made in China cf instead metal

- pp thermoplastic prepreg lightweight

Tags :

-

LFT-G PP Polyphenylene blends long carbon fiber thermoplastic resin original color sample available 12mmPP material Polypropylene fiber has remarkable performance. Compared with other fibers, polypropylene fiber has the lightest, warmest and most hydrophobic fiber properties. The density of polypropylene fiber is only 0.91g/cm3, which is the smallest among the five synthetic fibers and about 34% lighter than polyester fiber; the insulation rate of polypropylene fiber is 36.49%, which is the highest among the five synthetic fibers and 1.7 times that of polyester; the standard moisture regain rate of polypropylene fiber is almost zero, and the hydrophobic and moisture-conducting properties are the best. At the same time, polypropylene fiber has good acid and alkali resistance and heat aging properties. PP-LGF reinofrced material Long carbon fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. Its widespread use in aerospace and other advanced industries make it and a "high-tech" perception of consumers - you can use it to market products and create differentiation from competitors. Datasheet of PP-LCF Injection molding Aplication of PP-LCF More suitable for large parts and structural parts. Other application fields you can contact us for technical supports. Test 1. Heat Deflection Temperature Testing 2. Vicat Softening Temperature Testing 3. Tensile Testing 4. Flexural Strength Testing 5. Elongation Testing 6. Density Testing 7. Melt Flow Rate Testing 8. Impact Strength Testing. 9. Etc. Production process 1. The original carbon fiber is physically and chemically treated to remove impurities, improve surface activity, and enhance the mechanical properties and durability of the prepreg. 2. Add resin, curing agent, additives, etc. to form a formula to improve fluidity, hardness, and temperature stability. 3. The pretreated carbon fiber is placed on the machine and compounded with resin. 4. The machine solidifies the words and the two are fully bonded. 5. Cut into 5mm-24mm particles according to the needs of manufactured products。 Certification 1. Quality Management System ISO9001/16949 Certification 2. National Laboratory Accreditation Certificate 3. Modified Plastics Innovation Enterprise 4. Honorary Certificate 5. Heavy metal REACH & ROHS testing Frequently asked questions Q. What are the advantages of long carbon fiber materials? A. Thermoplastic LFT long carbon fiber material has high rigidity, good impact strength, low warpage, low shrinkage, electrical conductivity and electrostatic properties, and its mechanical properties are better than glass fiber series. Long carbon fiber has the characteristics of lighter and more convenient processing to replace metal products. Q. Are there any special process requirements of long carbon fiber injection molding products? A. We must consider the requirements of long carbon fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long carbon fiber is a relatively high cost material, and need to evaluate the cost performance problem in the selection process. Q. The cost of long fiber products is higher. Does it has a high recycling value? A. The thermoplastic LFT long fiber material can be recycled and reused very well

- best long carbon fiber pp lcf30 granules

- PLA Composite Pellets

- Modified Plastic pellets

- pp modified granules manufacturer

Tags :

-

LFT-G PLA Polylactic acid blends long carbon fiber thermoplastic resin original color can be recycled plasticWhat is the PLA? Poly(lactic acid), also known as poly(propylene glycol), is a polyester polymer obtained by polymerizing lactic acid as the main raw material, which is a new type of biodegradable material. PLA has good thermal stability, processing temperature 170-230℃, good solvent resistance, and can be processed in various ways, such as extrusion, spinning, biaxial stretching, and injection blow molding. In addition to being biodegradable, products made from PLA have good biocompatibility, gloss, transparency, handfeel and heat resistance. Why filling long carbon fiber? In the modified engineering plastics industry, long fiber reinforced composites are composites made from long carbon fiber, long glass fiber, aramid fiber or basalt fiber and a polymer matrix through a series of special modification methods. The most important feature of long fiber composites is that they have superior performance that the original materials do not have. If we classify them according to the length of the reinforcing materials added, they can be divided into: long fiber, short fiber and continuous fiber composites. Long carbon fiber composites are one kind of long fiber reinforced composites, which are a new fiber material with high strength and high modulus. It is a new material with excellent mechanical properties and many special functions. Application for reference What is the difference between Long glass fiber and Short glass fiber? As the fiber length increases, the stiffness and strength of the composite material gradually increases, but the dimensional complexity gradually decreases and the productivity gradually decreases. Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher toughness than short fiber, and the tensile strength is increased by 0.5-1 times. About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Main products Welcome to contact us!

- PLA pellets lcf 30 polymer

- self owing pla pellets

- best long carbon fiber pla lcf30 granules

- Modified materials PLA

- carbone fiber reinforced PLA pellets

- PLA with long carbon fiber

Tags :

-

LFT-G PA12 Polyamide12 30% Long Carbon Fiber composite higher performance lightweight sample availablePA12 information Long carbon chain nylon is a nylon with amide group in the main chain repeating unit of nylon molecule, and the length of methylene group between two amide groups is more than 10. We call it as long carbon chain nylon, including nylon 11, nylon 12, etc.. PA12 is nylon 12, also known as poly(dodecalactam) and poly(laurolactam), which is a kind of long carbon chain nylon. The basic raw material for polymerization is butadiene, a semi-crystalline - crystalline thermoplastic material. Nylon 12 is the most widely used long carbon chain nylon, it has most of the general properties of nylon, in addition to low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, PA12's raw material butadiene is only one-third the price of PA11's raw material castor oil, and can be used in most scenarios instead of PA11, and has wide applications in many fields such as automotive fuel hoses, air brake hoses, submarine cables, and 3D printing. Among long-chain nylon, PA12 has great advantages compared with other nylon materials, its advantages are the lowest water absorption, lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect, etc. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, to achieve the combination of lightweight and physical and chemical properties, with performance It has the advantages of light weight and physical and chemical properties. PA12-LCF If the base material is compared to concrete, the fiber is like steel reinforcement, and mixing the two is like adding steel reinforcement to concrete. If there is only concrete, the castings will easily crack under external forces, but once the high-strength reinforcement is added to it and the concrete wraps it sufficiently, they will become a single unit. When the object is subjected to external forces, the rebar can withstand most of the external forces, making the structural strength of this whole very high. Carbon fiber has many excellent properties, high axial strength and modulus of carbon fiber, low density, high specific performance, no creep, resistance to ultra-high temperature in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmittance. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness is also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. Datasheet for reference Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and grease resistance, medium resistance to alcohols and inorganic dilute acids and aromatics, good mechanical and electrical properties, and is a self-extinguishing material. Application Suitable for the automotive, sports parts, solar energy, high-end toys and other industries. Other products you may wonder PP-LCF PA6-LCF PA66-LCF ...

- Nylon polymer LCF

- extrusion level Nylon modified

- pa lcf30

- carbone fiber reinforced pa12 pellets

Tags :

-

LFT-G brand PA6 Nylon6 composite Long Carbon Fiber modified plastic 12mm in length original colorBackground At present, modern design tends to light weight requirements, the use of plastic proportion is increasing, no matter what industry, as long as the plastic can replace the absolutely no metal, plastic another advantage is the process cost is low, molding easier. Among the many polymer plastic materials, nylon and lead the way, especially in the automotive industry, nylon materials are essential. Therefore, it is necessary to understand the nylon industry. PA6 plastic Polyamide resin, the English name is polyamide, abbreviated as PA, commonly known as nylon (Nylon). It is a general term for polymers containing amide groups in the repeating units of the macromolecular main chain. It is one of the five major engineering plastics with the largest production, the most varieties, the most versatile species, with other polymer blends and alloys, etc., to meet different special requirements, widely used as a substitute for metal, wood and other traditional materials. The main varieties of nylon are nylon 6 (PA6) and nylon 66 (PA66), which occupy the absolute dominant position. Nylon 6 (PA6) is a polycaprolactam. The chemical and physical properties of PA6 are very similar to PA66, however, it has a lower melting point and a wide range of process temperatures. It has better impact and dissolution resistance than PA66, but is also more hygroscopic. Long Carbon Fiber compounds Long carbon fiber composite material is a kind of long fiber reinforced composite material, which is a new fiber material with high strength and high modulus fiber. LCF carbon fiber composite material shows high strength along the fiber axis direction, and has high strength and light weight, and has a full range of mechanical properties such as density, specific strength and specific modulus that are incomparable with other materials, which is a new material with excellent mechanical properties and many special functions. It is a new material with excellent mechanical properties and many special functions. Corrosion resistance: LCF carbon fiber composite materials have good corrosion resistance and can adapt to the harsh working environment. UV resistance: the ability to resist UV is strong, and the products are less damaged by UV. Abrasion and impact resistance: the advantage of comparing with general materials is more obvious. Low density: lower density than many metal materials, can achieve the purpose of light weight. Other properties: such as reducing warpage, improving rigidity, impact modification, increasing toughness, electrical conductivity, etc. LCF carbon fiber composites have higher strength, higher rigidity, lower weight, and excellent electrical conductivity compared with glass fiber. Datasheet Application PA6 is generally used for automotive parts, mechanical components, electronic and electrical products, engineering parts and other products. Product details Number Color Length MOQ Sample Package Delivery time Port of Loading PA6-NA-LCF30 Natural color (or as customized) 12mm about 1 ton Available 20kg/bag 7-15 days after shipment Xiamen Port About us Located in Xiamen, have over ten years of experience in the modified plastic industry. Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.view more

-

Xiamen LFT PPC reinforced long carbon fiber 12mm higher mechanical properties natural black best priceWhat is the PP-LCF? Polypropylene is a kind of polymer material with low cost, excellent performance and wide application. By carbon fiber reinforcement, the strength, heat deflection temperature and dimensional stability of polypropylene materials can be improved, which expands the application fields of polypropylene materials and is widely used in electronic appliances, automobiles and other fields. Especially in the automotive field, with the development of new energy vehicles and in the trend of automotive lightweighting, carbon fiber reinforced materials are more and more widely used in the automotive field. What is the advantages of PP-LCF? The modified polypropylene material reinforced by carbon fiber has a series of advantages such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat and impact resistance, corrosion resistance, and good vibration absorption. The datasheet was test by us, for reference only. What is the application of PP-LCF? High mechanical performance Meet the design trend of new energy vehicles Lower density meets the demand for lighter weight vehicles Other materials you may wonder PA6-LCF PA12-LCF PPS-LCF Test Processing Certifications Quality Management System ISO9001/16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testing Contact usview more

-

LFT-G raw material virgin composite PEEK filling Long Glass Fiber30% natural color high strength and rigidityPEEK-Long carbon fiber Polyetheretherketone (PEEK), the complete English name for polyetheretherketone, is a specialty engineering plastic with excellent performance, and has more advantages than other specialty engineering plastics, such as wear resistance, high temperature resistance, high strength and high modulus, flame retardant and radiation resistant, and so on. In addition polyetheretherketone (PEEK) has good thermal stability and melt flow above the melting point, so polyetheretherketone (PEEK) also has the typical processing properties of thermoplastics. PEEK resin is nontoxic, lightweight, corrosion-resistant, and one of the closest materials to the human skeleton, which is well compatible with the musculature, so it is often used instead of metal to make human bones. Carbon fiber-reinforced PEEK composites make up for the weaknesses of toughness and deviations in impact strength. Carbon fiber-reinforced PEEK composites can exhibit high mechanical strength and hydrolytic stability under conditions such as hot water, steam, solvents, and chemical reagents, and can be used to prepare various medical devices that require high-temperature steam sterilization. Advantages of PEEK-LCF PEEK has high rigidity, good dimensional stability, low coefficient of linear expansion, and can withstand great stress without significant elongation over time, and its low density and good processing properties make it suitable for parts with high requirements for fineness. Among these elements, carbon fiber materials overlap highly with the characteristics of PEEK. Carbon fiber is not only one of the typical lightweight materials, it is also outstanding in terms of mechanical properties. As a result, carbon fiber reinforced PEEK composites can reduce weight by at least 70% compared to traditional metal materials. PEEK material itself is very wear-resistant, and good interface bonding with carbon fibers to further enhance its wear resistance, through the carbon fiber reinforced PEEK composite parts and cobalt alloy materials for wear comparison experiments, the results show that: at 23 ℃, using the M-200 wear machine at 400 rpm after 100 minutes of wear, found that the carbon fiber reinforced PEEK composite surface smooth The wear marks were small, and the carbon fiber bonded well with PEEK without fiber extraction. In contrast, the cobalt alloy surface wear marks are very obvious, even a large number of wear particles appear, the metal internal impurities image visible. PEEK exhibits high mechanical strength and hydrolytic stability in hot water, steam, solvents and chemical reagents, etc. Datasheet for reference PEEK-LCF application Q&A 1. What are the types of thermoplastic carbon fiber composites? Carbon fiber thermoplastic composites are composites with carbon fiber as the reinforcing material and thermoplastic resin as the matrix. From the reinforcement method of carbon fiber, it can be divided into long-cut carbon fiber (LCF) reinforced thermoplastic composites, short-cut carbon fiber (SCF) reinforced thermoplastic composites and continuous carbon fiber (CCF) reinforced thermoplastic composites. Long-cut carbon fiber and short-cut carbon fiber mainly refer to the application length of carbon fiber materials, there is no strict fixed distinction between the two, generally between a few millimeters to a few centimeters, the more common specifications are 6mm, 12mm, 20mm, 30mm, 50mm. Carbon fiber thermoplastic composites can also be classified according to the thermoplastic resin. There are many common thermoplastic resins, such as PE, PP, PVC, etc. However, thermoplastic resin composites with carbon fiber reinforcement are mostly used in aerospace, precision equipment and other demanding working environments, therefore, carbon fiber thermoplastic composites are more often made of polyether ether ketone (PEEK), PPS, polyimide ( PI), polyetherimide (PAI) and other mid- to high-end thermoplastic resins as the matrix to achieve the optimization of material performance. 2. How does thermoplastic carbon fiber composite material achieve low cost and environmental protection? Thermoplastic carbon fiber composites are used to make parts for high-end machinery. They have excellent machinability, vacuum forming, stamping mold plasticity, and bending processability. For example, Teijin has been able to add a recycling process to the process according to specific needs, and to shred and mold the corners of thermoplastic carbon fiber composite materials after stamping to make recycled materials for making small products or for molding nuts and studs on carbon fiber prototypes. This method can greatly reduce the loss of raw materials, improve the efficiency of the use of thermoplastic carbon fiber composite materials, reduce the overall cost, and thus achieve the purpose of environmental protection. In addition, thermoplastic carbon fiber composites can reduce the molding cycle time compared with thermoset carbon fiber composi...

- PEEK with long carbon fiber

- factory in Xiamen thermoplastics

- peek cf30

- PEEK pellets lcf 30 polymer

- self owing peek pellets

Tags :

-

LFT-G PPS Polyphenylene sulfide composite long carbon fiber thermoplastic resin high rigidity and strengthPPS Information Polyphenylene sulfide (PPS) is not enhanced before modification, its disadvantages are brittle, poor toughness, low impact strength, after filling glass fiber, carbon fiber and other enhancements modified to overcome the above shortcomings, to obtain very good overall performance. PPS filling Long carbon fiber In the modified engineering plastics industry, long fiber reinforced composites are composites made from long carbon fibers, long glass fibers and polymer matrix through a series of special modification methods. The most important feature of long fiber composites is that they have superior performance that the original materials do not have. If we classify them according to the length of the reinforcing materials added, they can be divided into: long fiber, short fiber and continuous fiber composites. Long carbon fiber composites are one kind of long fiber reinforced composites, which are a new fiber material with high strength and high modulus. It is a new material with excellent mechanical properties and many special functions. Corrosion resistance: LCF carbon fiber composite materials have good corrosion resistance and can adapt to the harsh working environment. UV resistance: the ability to resist UV is strong, and the products are less damaged by UV. Abrasion and impact resistance: the advantage of comparing with general materials is more obvious. Low density: lower density than many metal materials, can achieve the purpose of light weight. Other properties: such as reducing warpage, improving rigidity, impact modification, increasing toughness, electrical conductivity, etc. LCF carbon fiber composites have higher strength, higher rigidity, lower weight, and excellent electrical conductivity compared with glass fiber. PPS TDS for reference PPS Application Other products you can also contact us for more technical advice. Q&A 1. Are carbon fiber composite products very expensive? The price of carbon fiber composite products is closely related to the price of raw materials, the level of technology and the number of products. The higher the performance of the raw material, the more expensive it is, such as the carbon fiber PEEK thermoplastic material used in orthopedics. Of course, the more complex the manufacturing process, the greater the working time and workload, and the increased production costs. However, the larger the order quantity, the lower the cost per product. In the long run, the superior performance of carbon fiber will extend the life of the product, reduce the number of maintenance, and is also very beneficial to reduce the cost of use. 2. Are carbon fiber composite products toxic? Carbon fiber composites are made of carbon fiber filaments mixed with ceramics, resins, metals and other substrates, and are generally not toxic. For example, the above-mentioned PEEK material is made of food-grade resin, which is very compatible with the human body and is not only harmless to humans, but also becomes a more ideal material for orthopedic surgery because of its high strength and elastic modulus close to the bone cortex. Carbon fiber medical bed plate, will be in daily contact with many patients body, will not have adverse effects on the human body, on the contrary, for the accuracy of medical diagnosis and a great help. 3. What is the difference between thermosetting carbon fiber composites and thermoplastic carbon fiber composites? Thermoset carbon fiber composites favor the role of curing agent in curing and molding. While thermoplastic carbon fiber composite products mainly rely on cooling down to achieve the shaping. Thermoplastic carbon fiber composites are not as popular as thermoset carbon fiber composites, mainly because they are expensive and are generally used in high-end industries. Thermoset carbon fiber composites are difficult to recycle due to the limitation of the resin matrix itself, and are generally not considered; thermoplastic carbon fiber composites can be recycled, and can be made twice as long as they are heated to a certain temperature. About us We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- PPS polyphenylent

- Low warpage electronic appliance

- pps lcf40 granules raw material

- PPS long carbon fiber extrusion

- pps LCf40 plastic injection part

- carbon fibre reinforced pps lcf pellet

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文