Product Name:PA66 LGF20, Nylon 66 Fiber Reinforced Plastic, Polyamide 66 composite

Form: Length about 12mm, High strength, High toughness

Advantage: More than 20 years experience product in fiber reinforced plastic .

Product Name:PA66 LGF20, Nylon 66 Fiber Reinforced Plastic, Polyamide 66 composite

Form: Length about 12mm, High strength, High toughness

Advantage: More than 20 years experience product in fiber reinforced plastic .

item no.:

PA66-NA-LGF20product origin:

Xiamen FujianColor:

Naturalshipping port:

xiamen portLead Time:

1-15

|

Product name |

Color | Product size | Material |

| LFT Long Glass Fiber20% PA66 Polyamide Nylon 66 Reinforced Thermoplastic Pellets | natural & discuss | 5-25mm | PA66 filing long glass fiber |

| Contract way | Packing | Deliver time | Port |

|

sale04@lfrtplastic.com |

25kg/bag | 3-15day | xiamen |

Nylon five engineering plastic production is the largest, the most varieties, the most widely used varieties.Nylon material under development in China in 1980, at that time, amount to 300 tons a year, now our nylon material consumption has reached 20 million tons a year, is widely used in medical, aviation, electrical equipment, mechanical equipment, shipbuilding, automobile manufacturing, household appliances, digital products, textile equipment, supplies, construction equipment, toys, and other fields.

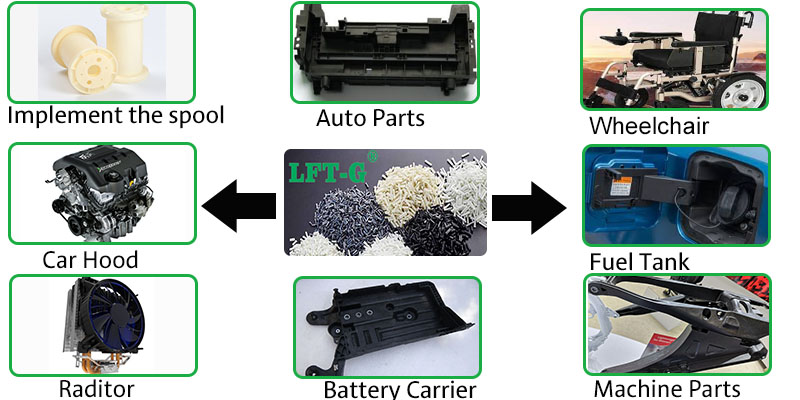

PA66 long fiber modified material , PA66 base fat after adding long glass fiber, processing growth of 12mm particles.Enhance its mechanical properties, suitable for a variety of structural requirements of parts, he is the first choice to replace metal.

|

Grade |

Filling Specification | Product number | Application range |

|

PA66 Long Glass Fiber General grade |

20% | PA66-NA-LGF20 |

atuomotive,electronic appliances,sports equipment,power tools,tool handles,high-speed rail accessories. |

| 30% |

PA66-NA-LGF30 |

||

| 40% |

PA66-NA-LGF40 |

||

| 50% | PA66-NA-LGF50 |

1. Medical field

Nylon material has mechanical strength and skin friendly feel that ordinary materials do not have, while medical equipment foot drop orthotics, rehabilitation wheelchairs and medical nursing beds usually need parts with certain bearing capacity, so PA66+15%GF is generally selected.

2. Automobile PA66+GF material can be used in engine intake pipe, engine cover cover, automobile chassis, engine fan blade, automobile air conditioning evaporator condenser, etc.

Start the intake pipe PA66+30%GF and PPS+30%GF, long-term temperature 140℃ more than 2000 hours.

Automobile chassis fender, engine fan blade PA66+PA+30%GF, need excellent toughness and strength, as well as very low deformation and dimensional stability.

Automotive air conditioning evaporator PA66+15%GF+10 talc, need good warping, long-term heat resistance, hydrolysis resistance, high size stability, high strength and toughness.

3. Various high-power fan blades and impellers

Modified PA66+30%GF material with high rigidity, high toughness, low warping, creep resistance and hydrolysis resistance.

4. Toys

Toy gun butt, drone propeller, motor bracket toys generally use high strength modified plastic (PA66+30%GF, PA66+30% carbon fiber).

Contracts email:sale02@lfrtplastic.com

Contracts wechat/whatsapp:+86 139 5009 5727