item no.:

PPS-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

PPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

About PPS-LGF compounds

PPS plastic (polyphenylene sulfide), English name: Polyphenylenesulfide, is a thermoplastic special engineering plastic with excellent comprehensive properties. Its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties. The product will make a metallic sound when it is dropped to the ground. .

Pure PPS is rarely used alone due to its brittle performance. Most of the PPS used is its modified variety. Glass fiber reinforced PPS is one of them.

PPS lengthened glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, and good product appearance. It can be used in water heater impellers, pump casings, joints, valves, chemical pump impellers and casings, cooling water impellers and Shells, home appliance parts, etc.

Basic Performance of PPS-LGF

1

Excellent overall performance.

PPS resin is a crystalline polymer with high hardness. Its crystal content is about 65% and its density is 1.34g/cm^3. It has excellent mechanical properties. Its tensile strength and bending strength are better than those of PA, PC, PBT, etc. It has extremely high rigidity and creep resistance. The mechanical properties will better after adding glass fiber reinforcement.

2

Excellent heat resistance.

Its melting point can reach 275~291℃, and its heat distortion temperature is 135℃. After glass fiber reinforcement, its heat distortion temperature can reach 260℃. In air, polyphenylene sulfide reaches the weakening temperature at about 400°C, and polyphenylene sulfide begins to decompose in air at 700°C. The long-term use temperature is 200~240℃, and the thermal stability of long-term continuous use is better than all current engineering plastics.

3

The dielectric strength is better.

PPS has a symmetrical molecular structure, non-polarity, and low water absorption, so its electrical insulation is very good. Compared with other engineering plastics, its dielectric constant is small, and its arc resistance is equivalent to that of thermosetting plastics. It can be used in high temperature, high humidity, frequency conversion, etc. Under harsh conditions, PPS can still maintain excellent electrical insulation.

4

preservative.

Because PPS has a high degree of crystallinity, it has excellent chemical resistance and is insoluble in any organic solvent below 200°C. In addition to strong oxidizing acids, it can withstand the erosion of various acids, alkalis, and salts. After being soaked in various chemicals for a long time, it still maintains high strength.

Materials Details

| Number | PPS-NA-LGF |

| Color | Natural color or Customized |

| Length |

6-25 mm |

| Package | 25kg/bag |

| MOQ | 25kg |

| Lead time | 2-15 days |

| Port of Loading | Xiamen Port |

| Trade terms | EXW/FOB/CFR/CIF/DDU/DDP |

About Xiamen LFT

Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

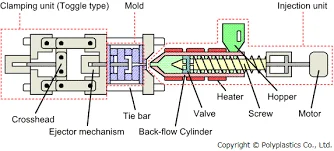

LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.