-

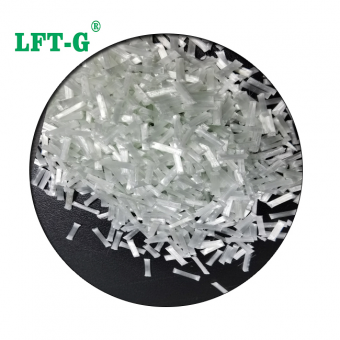

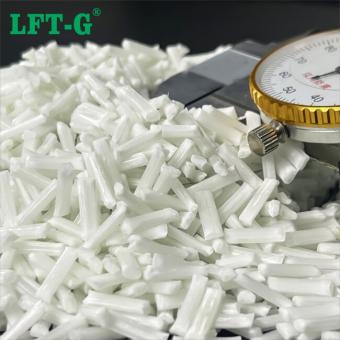

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.

- Compound plastic materials PP resin

- Polypropylene with long glass fiber

- pp filling glass fiber reinforced thermoplastic

- High strength modified material

- pp lgf lft PP GF30 high rigidity

- long glass fiber reinforced polypropylene

Tags :

-

Xiamen LFT ABS filling long glass fiber reinforced polymerabs lft manufactories granules polymer

- abs lft thermoplastic resin made in China

- abs lft glass fiber instead metal and steel good price

- abs lft glass fiber reinforced composite

- lft abs glass fiber Glass fiber reinforcement granules

- long glass fiber abs granules for engineering

Tags :

-

Xiamen LFT reinforcement Polypropylene long glass fiber modifiedLong glass fiber reinforcement thermoplastic polypropylene resin

- Long fiber reinforced thermoplastics composite PP

- metal replacement PP polymer glass fiber reinforced

- High fatigue and creep endurance

- China manufacturer Polypropylene good price

- long glass fiber modified PP for car parts gfrp PP GF30

- higher performance than short/chopped glass fiber filled compounds.

Tags :

-

Xiamen LFT high temperature resistance Polyphenylene sulfide PPS filled long glass fiber polymerPolyphenylene sulfide PPS plastic (polyphenylene sulfide) is a special engineering plastic with excellent comprehensive performance, high strength, the sound of metal, and the material is as hard as metal. It also has the characteristics of high temperature resistance, cold resistance, acid and alkali resistance, wear resistance, flame retardant V0, low warping and excellent electrical properties. Compared with metal, PPS material products are light in weight, which is particularly important for mechanical equipment requiring self-weight reduction, such as vehicles, ships and aircraft. PPS material strength is high, compared with the weight of metal, PPS strength is much higher than the general metal, is the highest strength of existing structural materials. PPS material has good chemical stability, and has good corrosion resistance to general acids, alkalis and other chemicals. The electrical properties of PPS materials are very outstanding, in the high temperature, high humidity, high frequency environment, high volume resistivity and insulation resistance remain unchanged, is an excellent insulation material. PPS material has good wear resistance and can be used to manufacture a variety of self-lubricating bearings, gears and seals. PPS material molding processing is convenient, products can often be formed at one time, and metal products always have to go through several, more than a dozen, or even dozens of processes to complete the processing. Long glass fiber compounds "Center Fill" is LFT compounds that are obtained through our technology by charging glass fiber rovings composed of thousands of filaments into an impregnation process and impregnating the glass fibers uniformly with molten thermoplastic resin and then cutting the resultant product into pellets. Significantly improved impact resistance Increased stiffness and strength Good heat resistance Improved creep and wear characteristics Reduced the degree of warpage and deformation Reinforced properties of recycled crystalline and non-crystalline resins Details Name Fiber content Color Length MOQ TDS FOB Price Delivery polyphenylene sulfide filled long glass fiber polymer 20%-60% Natural color/Customized 6-25mm 25KG/Bag Contact us for TDS USD8.8-11.1/KG By ship or air Company profile Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. Other materials you may interested PA66-NA-LGF PPA-NA-LCF PA12-NA-LGF

- Exceptional mechanical strength Polyphenylene sulfide plastic

- LFT PPS long glass fiber reinforced thermoplastic resin pellets

- PPS plastic granules high strength made in China

- PPS can be customized long cut fiber filament

- hot sell light weight plastic instead metal and steel

- engineering used plastic PPS good appearance gfrp

Tags :

-

Xiamen High toughness Thermoplastic Urethane filled Long Glass Fibertpu injection molding and extrusion grade polyurethane recycle material

- tpu long glass fiber thermoplasitc composite

- long glass fiber reinforced plastic

- tpu polyurethane plastic long glass fiber

- long fiber tpu thermoplastic modified plastic

- tpu and polyurethane lgf instead metal

- long fiber thermoplastic made in China manufacturer

Tags :

-

LFT-G TPU Thermoplastic Urethane filling long glass fiber materials compounds plasticWhat is TPU? TPU(Thermoplastic polyurethanes) name is elastomer rubber. It is mainly divided into polyester type and polyether type, its hardness range is wide (60HA-85HD), wear resistance, oil resistance, transparent, good elasticity, in daily necessities, sports goods, toys, decorative materials and other fields are widely used, halogen-free flame retardant TPU can also replace soft PVC to meet more and more fields of environmental protection requirements. The so-called elastic body refers to the glass transition temperature is lower than the room temperature, elongation at break >50%, the external force removed after the good recovery polymer material. Polyurethane elastomer is a special category of elastomer, polyurethane elastomer hardness range is very wide, performance range is very wide, so polyurethane elastomer is a kind of polymer material between rubber and plastic. It can be heated plasticized and has little or no crosslinking in chemical structure. Its molecules are basically linear, but there is some physical crosslinking. This type of polyurethane is called a TPU. Why filling long glass fiber? Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network. Performance is preserved in a wide range of environments. Compared with Short glass fiber Application Car doors and windows, Safty toe, Mechanical parts, Pneumatic nail gun boxes, Professional power tools, Nut and bolts, Etc. About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) and Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in legnth. The company's long-fiber continuous infiltration reinofrced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Quality Management System ISO9001&16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testing

- tpu lft injection molded made in China

- long fibre reinforced thermoplastics

- glass fiber reinforced plastics granules

- long glass fiber TPU low warping shoe sole

- long fiber composite TPU granules

- long glass fiber reinforced TPU lft

Tags :

-

LFT-G TPU Thermoplastic Urethane filled long glass fiber compoundsWhat is TPU? TPU(Thermoplastic polyurethanes) name is elastomer rubber. It is mainly divided into polyester type and polyether type, its hardness range is wide (60HA-85HD), wear resistance, oil resistance, transparent, good elasticity, in daily necessities, sports goods, toys, decorative materials and other fields are widely used, halogen-free flame retardant TPU can also replace soft PVC to meet more and more fields of environmental protection requirements. The so-called elastic body refers to the glass transition temperature is lower than the room temperature, elongation at break >50%, the external force removed after the good recovery polymer material. Polyurethane elastomer is a special category of elastomer, polyurethane elastomer hardness range is very wide, performance range is very wide, so polyurethane elastomer is a kind of polymer material between rubber and plastic. It can be heated plasticized and has little or no crosslinking in chemical structure. Its molecules are basically linear, but there is some physical crosslinking. This type of polyurethane is called a TPU. Why filling long glass fiber? Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network. Performance is preserved in a wide range of environments. Compared with Short glass fiber Application Car doors and windows, Safty toe, Mechanical parts, Pneumatic nail gun boxes, Professional power tools, Nut and bolts, Etc. About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) and Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in legnth. The company's long-fiber continuous infiltration reinofrced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Quality Management System ISO9001&16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testingview more

-

LFT-G TPU Thermoplastic Urethane filled long glass fiber compoundsWhat is TPU? TPU(Thermoplastic polyurethanes) name is elastomer rubber. It is mainly divided into polyester type and polyether type, its hardness range is wide (60HA-85HD), wear resistance, oil resistance, transparent, good elasticity, in daily necessities, sports goods, toys, decorative materials and other fields are widely used, halogen-free flame retardant TPU can also replace soft PVC to meet more and more fields of environmental protection requirements. The so-called elastic body refers to the glass transition temperature is lower than the room temperature, elongation at break >50%, the external force removed after the good recovery polymer material. Polyurethane elastomer is a special category of elastomer, polyurethane elastomer hardness range is very wide, performance range is very wide, so polyurethane elastomer is a kind of polymer material between rubber and plastic. It can be heated plasticized and has little or no crosslinking in chemical structure. Its molecules are basically linear, but there is some physical crosslinking. This type of polyurethane is called a TPU. Why filling long glass fiber? Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network. Performance is preserved in a wide range of environments. Compared with Short glass fiber Application Car doors and windows, Safty toe, Mechanical parts, Pneumatic nail gun boxes, Professional power tools, Nut and bolts, Etc. About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) and Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in legnth. The company's long-fiber continuous infiltration reinofrced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Quality Management System ISO9001&16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testingview more

-

Xiamen LFT Reinforced Plastic Thermoplastic Urethane Long Glass Fiber Filled Compoundstpu injection molding and extrusion grade polyurethane recycle materialview more

-

Xiamen LFT Polypropylene Copolymer High Impact Resistance Long Glass Fiber FilledWhat Is Copolymer? A copolymer is a polymer made up of more than one type of monomer unit. Copolymers are produced by polymerizing two or more types of monomer together in a process referred to as copolymerization. Copolymers produced in this way are sometimes also referred to as biopolymers. What Is the Purpose of Copolymer? The purpose of creating a copolymer is to manufacture a polymer with more desirable properties. Copolymers typically experience a lower crystallinity, higher glass transition temperature, and improved solubility. These characteristics are achieved through a process referred to as rubber toughening. Where Are Copolymers Used? Copolymers can be found in many industries, including in: Car parts, washing machine parts, water pump parts, water treatment components, furniture parts, etc. What Are the Advantages of Copolymer? The advantages of using copolymers include: 1.High shear resistance. 2.High operating temperature. 3.High corrosion resistance. 4.High impact resistance. 5.High dimensional stability. What is the Application of Polypropylene Long Glass Fiber Reinforcement? LFT-G production process LFT® is A LGF or LCF compound , through Centerfill manufacturing method which Offers exceptional Properties for weight and Cost reduction. With pellet length of 7-25mm and a range of 20%-70% of LGFor LCF content , LFT® Products family consist of Tailor made solutions to the Industry’s vast requirements , such as: LFT® - Fulfills heat stability requirements. LFT® - Offer Climate resistant Properties including UV resistance. LFT® - Ultra Performance & safety , with exceptional impact resistance Features, especially at low temperatures. LFT® - Cost Effective P.s. Centerfill manufacturing method:Centerfill uses our proprietary technology to introduce glass roving (GFR), which consists of several thousand filaments, into an impregnating device and melt the thermoplastic resin, uniformly impregnating between the filaments and then cutting them into pellets. Manufacture. Q & A Q. What are the differences and advantages of long fiber materials and staple fibers? A:Long-fiber reinforced composites show excellent mechanical properties compared to short fibers and are more suitable for applications requiring high strength. The impact performance of long fiber composites is 1-3 times higher than that of short fibers, tensile strength is more than 50% higher, and mechanical properties are 50-80% higher. Q. The product is easy to brittle, so changing to use long fiber reinforced thermoplastic materials can solve this problem? A: The overall mechanical properties must be improved. The characteristics of long glass fiber and long carbon fiber are the advantages in mechanical properties. It has 1-3 times higher (toughness) than short fiber , and the tensile strength(strength and rigidity) is increased by 0.5-1 times. Q. Using a more long fiber reinforced thermoplastic material, will it block the die hole due to the long length of the fiber or not ? A: When using long glass fiber or long carbon fiber, it is necessary to evaluate whether the product is suitable for LFT-G. If the product is too small or the dispensing is not suitable for long fiber materials. The long fiber itself has requirements for the mold nozzle. About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- LGF Glass Fiber Reinforced Thermoplastic Resin

- Manufacturer sell automovtive parts

- High quality raw materials

- Engineering Plastic Compounds Pellets

- High Mechanical Performance Hybrid Composites

- Can be recycled no toxic

Tags :

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.view more

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文