ABS glass fiber pellets Granules ABS virgin raw materials +glass fiber

-

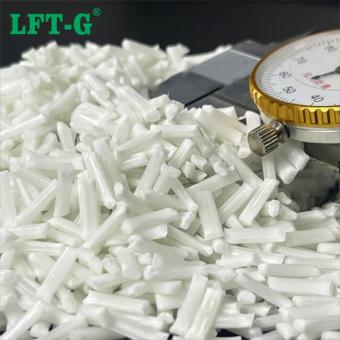

Glass Fiber Reinforced ABS Resin Pellets Injection MoldingAfter adding glass fiber to ABS, the rigidity, heat resistance and dimensional stability of the composite are significantly improved. In addition, the cost performance of ABS plus glass fiber is extremely good, which can meet the needs of manufacturers while reducing costs.

- abs plastic melting point

- abs plastic pellets

- abs granules manufacturer

- natural abs color

- abs glass fiber compound

- abs raw material

Tags :

-

Xiamen LFT ABS (Acrylonitrile Butadiene Styrene) Long Glass Fiber Reinforced Thermoplastic CompoundsABS-LGF (Glass Fiber Reinforced ABS) Overview ABS is a versatile engineering plastic known for chemical and thermal stability, strength, toughness, and glossy finish. It is widely used in consumer products such as toys and helmets, as well as automotive applications like interior trim, housings for electronics, and more. Reinforcing ABS with glass fiber significantly improves rigidity, heat resistance, and dimensional stability. ABS-LGF composites provide excellent cost-performance balance, helping manufacturers reduce costs while meeting production needs. About ABS-LGF Compounds Applications of Modified ABS 1. Automotive Parts: Instrument panels, fenders, interiors, lights, mirrors, audio systems. 2. Electronic & Electrical Components: IT and OA equipment shells, converters, power sockets. 3. Electronic Appliances: Switches, controllers, monitors, housings, brackets. 4. Home Appliances: Electrical components, control boxes. Advantages of ABS Injection Molding High Productivity: Efficient, low-waste process ideal for high-volume manufacturing. Complex Part Design: Capable of multi-featured components, including overmolding and metal inserts. Increased Strength: ABS provides excellent mechanical strength and durability. Flexible Color & Material Options: Easily colored, painted, or electroplated to improve environmental resistance. Decreased Waste: Low-wastage production, limited to sprue, runners, and flashing. Low Labor Cost: Highly automated process reduces human intervention and lowers cost per part. Material Details Number ABS-NA-LGF Color Natural or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead Time 2-15 days Port of Loading Xiamen Port Trade Terms EXW / FOB / CFR / CIF / DDU / DDP About Xiamen LFT Founded in 2009, Xiamen LFT Composite Plastics Co., Ltd. is a leading global supplier of long fiber reinforced thermoplastic materials, integrating R&D, production, and marketing. Our products are ISO9001 & IATF16949 certified, patented, and applied in automotive, aerospace, medical, new energy, military, sports equipment, and more. Compared to short fiber thermoplastics (1-2 mm fibers), our LFT materials (5-25 mm fibers) are fully impregnated with resin, ensuring superior mechanical performance. Base resins include PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Conventional fibers include glass and carbon fibers. Finished products can be used for injection molding, extrusion, or directly replace steel and thermoset components.

- High performance thermoplastic engineering plastics

- excellent heat resistance with filler

- injection molding products light weight

- automotive parts house hold appliances

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

Xiamen LFT-G ABS Acrylonitrile Butadiene Styrene long glass fiber reinforced for industrial useABS Plastic | Acrylonitrile Butadiene Styrene Engineering Thermoplastic ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent impact resistance, mechanical strength, and processing versatility. ABS plastic is an amorphous polymer commonly used in automotive, electrical, consumer, and industrial applications. What Is ABS Plastic? ABS plastic is a thermoplastic polymer produced by polymerizing acrylonitrile, butadiene, and styrene. Each component contributes specific performance advantages: Acrylonitrile – chemical resistance and thermal stability Butadiene – toughness and impact resistance Styrene – rigidity, surface quality, and processability Due to this balanced structure, ABS engineering plastic offers high impact resistance, good dimensional stability, and easy processing, making it one of the most versatile thermoplastics on the market. ABS is non-toxic in solid form, provides good electrical insulation, and is widely accepted as a safe and reliable material for mass production. Main Advantages of ABS Plastic As a general-purpose engineering thermoplastic, ABS plastic offers the following key advantages: Excellent impact resistance and toughness Good mechanical strength with low weight Easy injection molding, extrusion, and machining Good surface finish and paintability Low electrical and thermal conductivity Cost-effective and widely available ABS can withstand repeated heating and cooling cycles, making it suitable for recyclable applications and long-term industrial use. ABS Plastic vs PLA: Material Comparison ABS and PLA are both popular thermoplastics, but they serve very different application requirements. ABS is a tougher and more durable engineering plastic, while PLA is primarily used for prototyping and hobbyist 3D printing. ABS vs PLA: Mechanical Strength ABS offers higher impact resistance and toughness than PLA PLA is stiffer but more brittle ABS vs PLA: Heat Resistance ABS softening temperature: ~105°C PLA softening temperature: ~60°C Due to its superior heat resistance, ABS is better suited for functional parts exposed to elevated temperatures. ABS vs PLA: Dimensional Stability & Accuracy PLA is easier to print and produces dimensionally stable parts during 3D printing. ABS, however, tends to warp during printing but performs better in real-world mechanical applications once molded. ABS vs PLA: Surface Finish Both materials show visible layer lines in FDM printing. ABS can be vapor-smoothed using solvents such as acetone, resulting in a smooth and glossy surface, while PLA typically requires sanding or coating. ABS vs PLA: Environmental Impact PLA is biodegradable under industrial composting conditions ABS is not biodegradable but is recyclable PLA degradation requires controlled industrial conditions and can take decades in natural environments. ABS offers long service life and durability for industrial products. ABS vs PLA: Cost Comparison Both ABS and PLA are low-cost thermoplastics. ABS may be slightly more expensive, but the difference is generally minimal and application-dependent. Typical Applications of ABS Plastic Thanks to its balance of toughness, processability, and cost efficiency, ABS engineering plastic is widely used in: Automotive interior and exterior components Electrical and electronic housings Consumer products and appliances Industrial enclosures and structural parts Injection molded and extruded components

- ABS can be recycled plastic made in China

- thermoplastic resin raw materials

- abs for whole sell good price fiberglass

Tags :

-

ABS Pellets Glass FiberABS injection molding refers to the process of injecting molten ABS plastic into a mold at high pressures and temperatures. There are many ABS injection molding applications as it is a widely used plastic and can be found in the automotive, consumer product, and construction industries to name a few.

- reinforced glass fiber

- glass fiber reinforced polymer rebar

- glass fiber reinforced concrete panel

- abs plastic

- abs resin pellets

- engineering plastic

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS injection molding refers to the process of injecting molten ABS plastic into a mold at high pressures and temperatures. There are many ABS injection molding applications as it is a widely used plastic and can be found in the automotive, consumer product, and construction industries to name a few.

- ABS Long Glass Fiber Reinforced Polymer

- ABS long fiber reinforced

- lgf injection mold abs for engineering

- China manufacturer ABS GF fiber reinforced

- High-performance engineering plastic ABS composite

- Natural color abs materials with filler

Tags :

-

Long Glass Fiber Reinforced Composites ABS Series CopolymerABS injection molding refers to the process of injecting molten ABS plastic into a mold at high pressures and temperatures. There are many ABS injection molding applications as it is a widely used plastic and can be found in the automotive, consumer product, and construction industries to name a few.view more

-

High Tensile ABS Long Glass Fiber Polymer PelletsABS injection molding refers to the process of injecting molten ABS plastic into a mold at high pressures and temperatures. There are many ABS injection molding applications as it is a widely used plastic and can be found in the automotive, consumer product, and construction industries to name a few.

- flammability properties

- lightweight composite

- glass fiber reinforced polymer price per kg

- ABS GF

- ABS electronics

- ABS Car parts

Tags :

-

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS also has good dimensional stability and can be easily machined or drilled after molding.

- Modified material lft injection molding

- ABS compounds long glass fiber

- reinforced material abs filling lgf

- ABS-LGF30 thermoplastic resin

- Thermoplastic resin ABS

Tags :

-

Glass Fiber Reinforced ABS Resin Pellets Injection MoldingAfter adding glass fiber to ABS, the rigidity, heat resistance and dimensional stability of the composite are significantly improved. In addition, the cost performance of ABS plus glass fiber is extremely good, which can meet the needs of manufacturers while reducing costs.view more

-

High Impact Resistance ABS Long Glass Fiber Plastic Injection MoldingABS is often used as a replacement for metal in the automotive industry. Various automotive parts that look for weight reduction factors use ABS thermoplastic.

- glass fiber reinforced composite

- abs plastic molds

- abs plastic materials

- abs plastic enclosure

- abs plastic cost

Tags :

-

ABS Composite Pellets with 20-60% Long Glass Fiber ContentABS long glass fiber reinforced material offers enhanced strength, impact resistance, and dimensional stability, making it ideal for demanding structural applications. With its excellent processability and toughness, it is widely used in automotive, electronics, and industrial components.view more

-

LFT ABS Plastic Long Glass Fiber Reinforced CompositesABS is sturdy, lightweight, and ductile, being easily machined but retaining good resistance to chemicals, impacts, and abrasions. In addition, ABS is more heat-resistant than other thermoplastics in its weight class and can withstand multiple cycles of heating/cooling, making it a fully recyclable plastic.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文