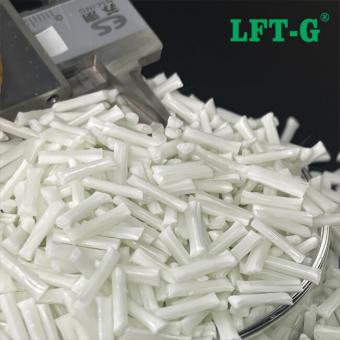

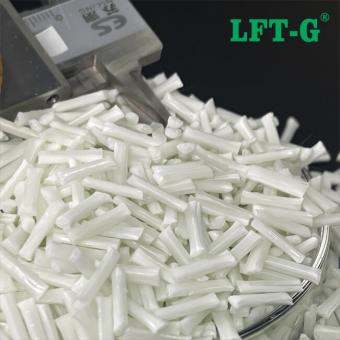

High-strength long glass fiber LGF modified nylon PA6 Long Glass fiber Reinforced Polyamide nylon PA6 has higher mechanical properties than ordinary modified PA6 nylon. Excellent long-term heat resistance, dimensional stability, can replace ordinary aluminum alloy materials, The cost is lower than that of metal materials.

-

Xiamen LFT-G Nylon 6 Polyamide 6 composite Long Glass Fiber modified plastic 12mm original colorPA6 Material Overview PA6 (Polyamide 6) is a widely used engineering plastic with excellent balanced performance. Its raw materials are readily available and cost-effective, making it accessible without dependence on foreign technology. However, PA6 has some limitations such as high water absorption, lower low-temperature impact toughness, and moderate dimensional stability. To overcome these limitations, PA6 is often reinforced with glass fiber (GF) to enhance mechanical properties. PA6-LGF (Long Glass Fiber Reinforced PA6) 1. Influence of Glass Fiber Content Glass fiber content is a key factor in the performance of reinforced composites. Increasing fiber content increases fiber density, thinning the PA6 matrix between fibers. This enhances impact toughness, tensile strength, and bending strength. Example: For PA6-LGF, increasing fiber content to 35% raised notch impact strength from 24.8 J/m to 128.5 J/m. However, excessive fiber content can reduce impact strength. Bending strength also improves as fibers transfer stress and absorb energy when broken, with experimental results showing bending modulus up to 4.99 GPa for 35% LGF. 2. Influence of Fiber Retention Length Fiber length significantly affects mechanical properties. When fiber length is below the critical length, increasing length improves resin-fiber bonding and tensile load resistance. When fiber exceeds the critical length, longer fibers absorb more impact energy and improve impact strength, as the number of fiber ends (crack initiation points) decreases. Example: At 40% fiber content, increasing fiber length from 4mm to 13mm improved tensile strength from 154.8 MPa to 164.4 MPa, with bending strength and notched impact strength increasing by 24% and 28%, respectively. Fibers longer than 7mm enhance warping resistance and mechanical stability under high temperature and humidity. Technical Data Reference (TDS) PA6-LGF can be reinforced with 20%-60% long glass fiber depending on product requirements. Compared to unreinforced PA6, PA6-LGF offers enhanced strength, heat resistance, impact resistance, dimensional stability, and reduced warping. The following TDS shows the data for PA6-LGF30. Applications of PA6-LGF PA6-LGF is widely used in automotive, electronic/electrical, and machinery/engineering parts. Automotive Parts Lightweight and miniaturization trends promote PA6-LGF use in engines, electrical systems, and body components. Electronic & Electrical Components Excellent flame retardancy and corrosion resistance make PA6-LGF suitable for switchgear, circuit breakers, contactors, connectors, and cable protection tubes. Mechanical & Engineering Parts Good impact resistance, wear resistance, and self-lubrication properties allow PA6-LGF to be used in machinery and engineering accessories. About Xiamen LFT Composite Plastics Co., Ltd. Xiamen LFT focuses on Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) reinforced thermoplastics. Our LFT materials support injection molding (LFT-G) and extrusion molding, as well as LFT-D molding, with fiber lengths from 5–25mm. Our products are ISO9001 & IATF16949 certified, patented, and widely used in automotive, electronics, industrial, and engineering applications.

- PA6 thermoplastic resin materials

- nylon 6 granules

- glass fiber reinforced plastics granules

- long fiber compounds pa6

- Injection molding plastic

- LFT-G reinforced material

Tags :

-

LFT-G PA6 Polyamide6 nylon6 filling long glass fiber40 orginal color for automotive partsPA6 & PA6-LGF Long Glass Fiber Reinforced Nylon PA6, also known as Nylon 6, is a high-performance polyamide widely used in engineering plastics, fibers, and films. It is a thermoplastic polymer with repeating amide groups (-NH-CO-) in the main chain, offering strong mechanical properties and versatile processing capabilities. What is PA6 Plastic? PA6 is an aliphatic polyamide that provides excellent strength, wear resistance, and chemical resistance to weak acids, alkalis, and certain organic solvents. Its lightweight and processable nature make it widely applied in fibers, engineering plastics, and thin films. However, the polar amide groups in PA6 easily form hydrogen bonds with water molecules, which can result in high moisture absorption, dimensional changes, and reduced impact strength in dry or low-temperature conditions. Advantages of PA6 High mechanical strength and toughness with excellent tensile and compressive properties Outstanding fatigue resistance, maintaining strength after repeated bending High softening point, heat resistant Low friction and wear-resistant surface Corrosion resistance to alkalis, salts, weak acids, oils, and most solvents Self-extinguishing, non-toxic, odorless, and good weather and biological resistance Excellent electrical insulation even in high humidity environments Lightweight, easy to dye, and easy to mold due to low melting viscosity Limitations of PA6 High moisture absorption (up to 3% when saturated) Poor light and thermal stability; prolonged high-temperature exposure may cause discoloration and surface cracking Strict injection molding requirements; trace moisture can affect product quality Dimensional stability is sensitive to thermal expansion and wall thickness variations Not resistant to strong acids or oxidizing agents; unsuitable for acid-resistant applications Why Reinforce PA6 with Long Glass Fiber? To overcome the natural limitations of PA6, long glass fiber (LGF) reinforcement is applied. PA6-LGF composites combine the lightweight, chemical, and heat resistance of PA6 with the mechanical strength and dimensional stability of long glass fibers. LGF reinforcement improves tensile, compressive, and flexural strength, reduces shrinkage, enhances fatigue resistance, and provides improved thermal and chemical stability. This makes PA6-LGF ideal for high-performance structural components. Applications of PA6-LGF PA6 reinforced with 30% long glass fiber (30% LGF) is widely used in: Power tool shells and components Engineering machinery parts Automobile structural and functional components The composite improves mechanical strength, dimensional stability, heat resistance, aging resistance, and fatigue resistance. Its fatigue strength can be up to 2.5x that of unreinforced PA6. Processing and Forming Tips for 30% PA6-LGF Shrinkage is reduced to ~0.3% compared with 1–1.5% for pure PA6. Excessive fiber content may cause surface floating fibers and poor compatibility. 30% LGF is recommended for balanced performance. Recycled material content should be kept below 25% to avoid color and mechanical property degradation. Gradual cooling after molding prevents warping due to fiber orientation during injection molding. Mold design, gate position, and temperature control are critical. Customers & Staffs Certificates

- Polyamide 6 composite

- lgf thermoplastic resin

- High impact PA6

- injection molding plastic

- pa6 filling long glass fiber

- Reinforced plastic

Tags :

-

PA6 Pellets Glass FiberIn the automotive industry, it is used because it is cheaper and lighter than metal. In machines, it is used over other materials due to its high flexibility and durability.

- nylon 6 pa6

- fiber reinforced nylon

- reinforced glass fiber

- nylon compounds

- glass fibre reinforced nylon

- glass fiber reinforced plastic

Tags :

-

LFT-G Polyamide6 nylon6 filling long glass fiber orginal color for automotive partsThe main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension. This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance.

- Polyamide 6 composite properties

- lgf thermoplastic resin good price

- High impact PA6 instead metal plastic

- injection molding plastic gf30 filter

- pa6 filling long glass fiber customized

- Reinforced plastic lightweight compounds

Tags :

-

Long Glass Fiber Reinforced Composites PA 6 Series CopolymerWith an experienced technical team in the industry, we provide high-quality Nylon 6 long glass fiber composite materials to help customers improve product performance and optimize production costs.

- pa6 glass fiber

- pa6 compound

- pa6 plastic material

- pa6 pellets

- custmized dyed nylon pa6 supply

Tags :

-

High Toughness Nylon PA6 Long Glass Fiber Polymer PelletsPolyamide, which is also known by Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials.

- flammability properties

- lightweight composite

- glass fiber reinforced polymer price per kg

- nylon composites

- polyamide 6

- nylon glass

Tags :

-

LFT-G Polyamide6 nylon6 filling long glass fiber orginal color for automotive partsThe main advantages of nylon 6 are its stiffness and resistance to abrasion. Moreover, this material has excellent impact strength, wear resistance, and electrical insulating properties. Nylon 6 is a highly elastic and fatigue-resistant material, meaning it will return to its original proportions after being distorted by tension. This polyamide is non-toxic and can be combined with glass or carbon fibers to increase performance.view more

-

Glass Fiber Reinforced Nylon 6 Resin Pellets High StrengthWhen molding nylon 6, the material is sometimes injected with a specified amount of glass fibers (usually between 20% and 60%) to boost its tensile strength. Glass fibers improve stiffness. Moreover, since UV radiation can be harmful to nylon, a UV stabilizer is frequently added to the material before injection molding to decrease the possible degradation of the item with time.

- fiberglass nylon 6

- thermoplastic composite materials

- nylon pa6 plastic material

- composites non-destructive testing

- composites for ev battery

- polypropylene disadvantages

Tags :

-

High Stifiness PA 6 Long Glass Fiber Plastic White or Black ColorPA6 refers to polyamide 6, which is a widely used engineering plastic with excellent mechanical strength, wear resistance, and chemical stability. Adding long glass fibers to PA6 can significantly enhance the material’s mechanical properties, such as strength, rigidity, impact resistance, and dimensional stability.

- glass fiber reinforced nylon

- pa6 polyamide

- glass fiber reinforced polymers

- glass fiber manufacturer

Tags :

-

Nylon 6 Composite Pellets with 20-60% Long Glass Fiber ContentLong glass fiber reinforced PA6 offers high mechanical strength, excellent heat resistance, and superior dimensional stability for demanding engineering applications. The addition of long glass fibers significantly enhances its stiffness and durability compared to unfilled PA6.view more

-

LFT Nylon Series Polyamide 6 Long Glass Fiber Reinforced CompositesPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials.

- Nylon composites

- Long-term light resistance plastic

- Fiberglass composites

- COMPOSITION OF POLYPROPYLENE COMPOUNDS

- LFT granules

- Plastic for automotive parts

Tags :

-

High Toughness Polyamide 6 Glass Fiber Polymer Wide ApplicationsWhen molding nylon 6, the material is sometimes injected with a specified amount of glass fibers (usually between 20% and 60%) to boost its tensile strength. Glass fibers improve stiffness.

- pa6 filament

- pa plastic

- polyamide and nylon

- pa plastic material

- Engineering thermoplastics supplier

- replacement for metal

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文