-

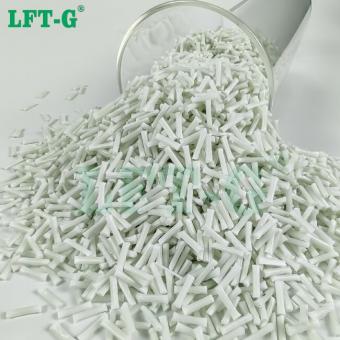

MXD6 Polyamide Composite Pellets with 20-60% Long Glass Fiber ContentMXD6 is a high-performance semi-aromatic polyamide known for its exceptional gas barrier properties, mechanical strength, and thermal stability. It is widely used in automotive, packaging, and industrial applications where durability and chemical resistance are essential. Ideal for structural and functional components, MXD6 delivers reliable performance in demanding environments.view more

-

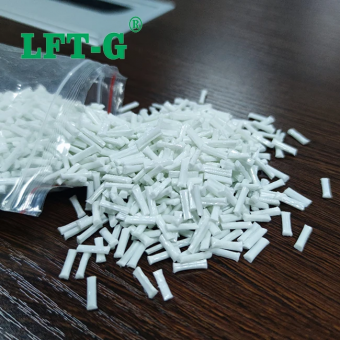

Glass Fiber Reinforced PE High Density Resin Pellets Injection MoldingThis material combines high-density polyethylene (HDPE) with long glass fibers for enhanced mechanical strength, impact resistance, and dimensional stability. It is ideal for structural applications requiring durability, lightweight, and chemical resistance, commonly used in automotive, industrial, and outdoor products.

- fiber reinforced hdpe composite pipe

- hdpe glass

- metal replacement solutions

- thermoplastic composite materials

- lft pellets

- long fibres composites

Tags :

-

Glass Fiber Reinforced PLA Resin Pellets Injection MoldingPLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance. By incorporating long glass fibers, the performance of PLA is significantly improved, making it suitable for demanding applications.

- pps plastic

- long-fiber thermoplastic composite solutions

- pla plastic pellets

- thermoplastic glass fiber composite

- thermoplastic gfrp

Tags :

-

Glass Fiber Reinforced ABS Resin Pellets Injection MoldingAfter adding glass fiber to ABS, the rigidity, heat resistance and dimensional stability of the composite are significantly improved. In addition, the cost performance of ABS plus glass fiber is extremely good, which can meet the needs of manufacturers while reducing costs.

- abs plastic melting point

- abs plastic pellets

- abs granules manufacturer

- natural abs color

- abs glass fiber compound

- abs raw material

Tags :

-

Excellent Regidity PBT Long Glass Fiber Plastic Injection MoldingAdding glass fiber to PBT is a commonly used method to enhance and modify PBT. The bonding force between glass fiber and PBT resin is good. After adding a certain amount of glass fiber to PBT resin, it can not only maintain the original advantages of PBT resin such as chemical resistance and processability, but also greatly improve its mechanical properties and overcome the problems. PBT resin notch sensitivity.view more

-

Glass Fiber Reinforced PLA Resin Pellets Injection MoldingPLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance. By incorporating long glass fibers, the performance of PLA is significantly improved, making it suitable for demanding applications.view more

-

LFT-G PPS Polyphenylene sulfide LGF composite long glass fiber customized engineering plasticsPPS & PPS-LGF | High Performance Engineering Plastic body { font-family: Arial, Helvetica, sans-serif; line-height: 1.6; color: #333; } h2 { font-size: 24px; margin-top: 40px; } h3 { font-size: 20px; margin-top: 25px; } p { font-size: 16px; margin: 12px 0; } ul { font-size: 16px; margin-left: 20px; } table { width: 100%; border-collapse: collapse; margin-top: 20px; } table, th, td { border: 1px solid #000; } th, td { padding: 10px; text-align: center; font-size: 16px; } img { max-width: 100%; margin: 20px 0; } What Is PPS? Polyphenylene Sulfide (PPS) is a high-performance engineering thermoplastic known for its excellent heat resistance, chemical stability, flame retardancy, and mechanical strength. Through reinforcement and modification, PPS offers a well-balanced combination of physical, mechanical, and electrical properties. PPS features outstanding dimensional stability, corrosion resistance, and electrical insulation performance, making it suitable for harsh industrial environments. Key Characteristics of PPS Excellent high-temperature resistance High hardness and wear resistance Strong creep resistance under long-term load Excellent electrical properties over a wide temperature range Low sensitivity of mechanical properties to temperature changes Unmodified PPS is naturally brittle and has relatively low impact strength. These limitations can be effectively overcome through fiber reinforcement and material modification. What Is PPS-LGF? PPS-LGF refers to Polyphenylene Sulfide reinforced with Long Glass Fiber. Among engineering plastics, PPS-LGF stands out for its superior heat resistance, structural strength, and long-term reliability. Heat deflection temperature (HDT) above 260°C Chemical resistance second only to PTFE Low molding shrinkage and extremely low water absorption Excellent flame retardancy and vibration fatigue resistance Outstanding electrical insulation even in high humidity and high-temperature environments By incorporating long glass fibers, PPS-LGF significantly improves toughness and impact strength, overcoming the brittleness of pure PPS and delivering excellent comprehensive performance. In many applications, PPS-LGF can replace metals such as stainless steel, copper, aluminum, and alloys—making it an ideal material for metal replacement and lightweight design. Applications of PPS-LGF PPS-LGF is widely used in industries requiring high strength, heat resistance, and chemical stability, including: Automotive components Aerospace structures Household appliances Mechanical and structural parts Chemical processing equipment Electrical insulation and corrosion-resistant components Product Details Grade Color Pellet Length MOQ Packaging Sample Delivery Time Port of Loading PPS-NA-LGF30 Natural (Customizable) ≥ 5–25 mm 25 kg 25 kg / bag Available 7–15 days after shipment Xiamen Port Production Process Our PPS-LGF materials are produced using advanced long-fiber impregnation technology, ensuring excellent fiber length retention, uniform dispersion, and stable mechanical performance. Trademarks and Patents Our materials are supported by proprietary technologies, registered trademarks, and patented processes to ensure consistent quality and reliable performance. Teams and Customers Backed by an experienced R&D and production team, our PPS-LGF materials are trusted by customers worldwide across automotive, industrial, and electrical sectors. What We Offer LFT & LFRT material technical data and advanced design support Mold-front design recommendations and optimization Professional technical support for injection molding and extrusion processing

- PPS Long glass fiber 40

- pps compounds lgf

- pps resin materials lft

- lft-g pps reinforced plastic

- long glass fiber filling pps

- termoplastic resin pps lgf

Tags :

-

Xiamen LFT ABS (Acrylonitrile Butadiene Styrene) Long Glass Fiber Reinforced Thermoplastic CompoundsABS-LGF (Glass Fiber Reinforced ABS) Overview ABS is a versatile engineering plastic known for chemical and thermal stability, strength, toughness, and glossy finish. It is widely used in consumer products such as toys and helmets, as well as automotive applications like interior trim, housings for electronics, and more. Reinforcing ABS with glass fiber significantly improves rigidity, heat resistance, and dimensional stability. ABS-LGF composites provide excellent cost-performance balance, helping manufacturers reduce costs while meeting production needs. About ABS-LGF Compounds Applications of Modified ABS 1. Automotive Parts: Instrument panels, fenders, interiors, lights, mirrors, audio systems. 2. Electronic & Electrical Components: IT and OA equipment shells, converters, power sockets. 3. Electronic Appliances: Switches, controllers, monitors, housings, brackets. 4. Home Appliances: Electrical components, control boxes. Advantages of ABS Injection Molding High Productivity: Efficient, low-waste process ideal for high-volume manufacturing. Complex Part Design: Capable of multi-featured components, including overmolding and metal inserts. Increased Strength: ABS provides excellent mechanical strength and durability. Flexible Color & Material Options: Easily colored, painted, or electroplated to improve environmental resistance. Decreased Waste: Low-wastage production, limited to sprue, runners, and flashing. Low Labor Cost: Highly automated process reduces human intervention and lowers cost per part. Material Details Number ABS-NA-LGF Color Natural or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead Time 2-15 days Port of Loading Xiamen Port Trade Terms EXW / FOB / CFR / CIF / DDU / DDP About Xiamen LFT Founded in 2009, Xiamen LFT Composite Plastics Co., Ltd. is a leading global supplier of long fiber reinforced thermoplastic materials, integrating R&D, production, and marketing. Our products are ISO9001 & IATF16949 certified, patented, and applied in automotive, aerospace, medical, new energy, military, sports equipment, and more. Compared to short fiber thermoplastics (1-2 mm fibers), our LFT materials (5-25 mm fibers) are fully impregnated with resin, ensuring superior mechanical performance. Base resins include PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Conventional fibers include glass and carbon fibers. Finished products can be used for injection molding, extrusion, or directly replace steel and thermoset components.

- High performance thermoplastic engineering plastics

- excellent heat resistance with filler

- injection molding products light weight

- automotive parts house hold appliances

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

High strength PA12 nylon12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.

- Nylon12 filling long glass fiber reinforced plastic

- Durability high mechanical properties

- Photovoltaic industry compounds

- Injection grade thermoplastic resin

- 24h service customized plastic instead metal

- Supplier price good price pa6 composites

Tags :

-

Nylon series Polyamide 66 Long Glass Fiber Reinforced Thermoplastic ResinPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials. About PA66-LGF compounds Nylon 6,6, also written as nylon 6-6, nylon 66, or nylon 6/6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66. It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6. The advantages of nylon 6,6 are that the yield strength is higher than nylon 6 and nylon 610. It has high strength, toughness, rigidity, and low coefficient of friction in a wide temperature range. In addition, it is oil resistant and resistant to chemical reagents and solvents. However, PA66 has strong hygroscopicity and poor dimensional stability, which limits its application. In order to obtain nylon 66 engineering material with higher strength, it should be modified by glass fiber reinforcement. The mechanical properties of long glass fiber reinforced nylon 66 (LGFR-PA66) are obviously better than those of short glass fiber reinforced nylon 66 (SGFR-PA66), and the molding processing performance is also better. It can be molded by various molding methods such as injection molding and compression molding, and complex components can also be formed. Therefore, long glass fiber reinforced nylon 66 can be widely used in building materials, aerospace, electronic devices, furniture and other fields, especially in the automotive industry application market. The production process of long glass fiber reinforced nylon 66 is different from that of short glass fiber reinforced nylon 66. The short glass fiber reinforced nylon 66 particle is chopped under the friction and shearing of screw and barrel, and the short glass fiber reinforced nylon 66 particle is obtained with the length of glass fiber monofilament about 0.5mm. The length of some glass fiber monofilament in the final product is lower than the critical length of reinforcement, and the glass fiber is easy to be extracted from the nylon 66 matrix when the product is stressed. The strength of glass fiber is not fully utilized, and the mechanical properties of the product are not high. Long glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer. Materials Details Number PA66-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.view more

-

Xiamen LFT-G Nylon 6 Polyamide 6 composite Long Glass Fiber modified plastic 12mm original colorPA6 Material Overview PA6 (Polyamide 6) is a widely used engineering plastic with excellent balanced performance. Its raw materials are readily available and cost-effective, making it accessible without dependence on foreign technology. However, PA6 has some limitations such as high water absorption, lower low-temperature impact toughness, and moderate dimensional stability. To overcome these limitations, PA6 is often reinforced with glass fiber (GF) to enhance mechanical properties. PA6-LGF (Long Glass Fiber Reinforced PA6) 1. Influence of Glass Fiber Content Glass fiber content is a key factor in the performance of reinforced composites. Increasing fiber content increases fiber density, thinning the PA6 matrix between fibers. This enhances impact toughness, tensile strength, and bending strength. Example: For PA6-LGF, increasing fiber content to 35% raised notch impact strength from 24.8 J/m to 128.5 J/m. However, excessive fiber content can reduce impact strength. Bending strength also improves as fibers transfer stress and absorb energy when broken, with experimental results showing bending modulus up to 4.99 GPa for 35% LGF. 2. Influence of Fiber Retention Length Fiber length significantly affects mechanical properties. When fiber length is below the critical length, increasing length improves resin-fiber bonding and tensile load resistance. When fiber exceeds the critical length, longer fibers absorb more impact energy and improve impact strength, as the number of fiber ends (crack initiation points) decreases. Example: At 40% fiber content, increasing fiber length from 4mm to 13mm improved tensile strength from 154.8 MPa to 164.4 MPa, with bending strength and notched impact strength increasing by 24% and 28%, respectively. Fibers longer than 7mm enhance warping resistance and mechanical stability under high temperature and humidity. Technical Data Reference (TDS) PA6-LGF can be reinforced with 20%-60% long glass fiber depending on product requirements. Compared to unreinforced PA6, PA6-LGF offers enhanced strength, heat resistance, impact resistance, dimensional stability, and reduced warping. The following TDS shows the data for PA6-LGF30. Applications of PA6-LGF PA6-LGF is widely used in automotive, electronic/electrical, and machinery/engineering parts. Automotive Parts Lightweight and miniaturization trends promote PA6-LGF use in engines, electrical systems, and body components. Electronic & Electrical Components Excellent flame retardancy and corrosion resistance make PA6-LGF suitable for switchgear, circuit breakers, contactors, connectors, and cable protection tubes. Mechanical & Engineering Parts Good impact resistance, wear resistance, and self-lubrication properties allow PA6-LGF to be used in machinery and engineering accessories. About Xiamen LFT Composite Plastics Co., Ltd. Xiamen LFT focuses on Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) reinforced thermoplastics. Our LFT materials support injection molding (LFT-G) and extrusion molding, as well as LFT-D molding, with fiber lengths from 5–25mm. Our products are ISO9001 & IATF16949 certified, patented, and widely used in automotive, electronics, industrial, and engineering applications.

- PA6 thermoplastic resin materials

- nylon 6 granules

- glass fiber reinforced plastics granules

- long fiber compounds pa6

- Injection molding plastic

- LFT-G reinforced material

Tags :

-

Xiamen LFT PP Polypropylene engineeing plastic long glass fiber composite granules 12mmWhat is Long Glass Fiber (LGF)? Long glass fiber reinforced plastics (LFT) are engineered materials in which long glass fibers and additives are incorporated into a base thermoplastic. This significantly improves mechanical strength, heat resistance, dimensional stability, and the overall performance of the material. Why Reinforce with Long Glass Fiber? High heat resistance: LFT significantly increases the thermal performance, especially for nylon-based plastics. Reduced shrinkage & higher rigidity: Fiber reinforcement restricts polymer chain movement, improving dimensional stability and stiffness. Improved impact resistance: Reinforced plastics are less prone to stress cracking and have better toughness. High strength: Long glass fibers increase tensile, compressive, and bending strength. Flame retardancy: Most LFT materials are self-extinguishing due to additives and fiber content. Why Choose Long Glass Fiber over Short Glass Fiber? Longer fiber length significantly enhances mechanical properties. High specific stiffness and strength with excellent impact resistance, ideal for automotive applications. Superior creep resistance and dimensional stability for precision parts. Excellent fatigue resistance for long-life components. Improved stability under hot and humid environments. Minimal fiber damage during molding due to relative fiber movement in the mold. Appearance of PP-LGF Applications of PP-LGF Automotive Parts Front end modules, door modules, shift mechanisms, electronic accelerator pedals, dashboards, cooling fans, battery carriers, bumper brackets, underbody protection plates, sunroof frames, etc. – replacing reinforced PA or metal components. Household Appliances Washing machine drums, brackets, air conditioning fans, etc. – replacing short glass fiber reinforced PA and metal components. Communications, Electronics, Electrical Appliances High-precision connectors, igniter components, coil shafts, relay bases, microwave transformer frames, solenoid valve housings, scanner components, etc. Other Applications Power tool housings, water pump/meter housings, impellers, bicycle frames, skis, locomotive pedals, safety helmets, safety shoes – replacing short fiber reinforced PA or PPO. Datasheet for Reference About Us Xiamen LFT Composite Plastics Co., Ltd. is a leading supplier of Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) reinforced thermoplastics. Our LFT materials support injection molding, extrusion molding, and are available in fiber lengths of 5–25mm, tailored to customer requirements. ISO9001 & IATF16949 certified, our products are patented and widely used in automotive, electronics, industrial, and defense applications. What We Offer Technical data and guidance for LFT & LFRT materials. Mold design recommendations for optimized production. Injection molding and extrusion support for consistent product quality.

- Polypropylene filling lgf GFRP 30

- thermopalstic Polymer virgin grade

- LFT-G car parts home appliance parts

- PP resin GF made in China modified plastic

- long fiber compounds pp instead metal and steel

- injection molding pp composite

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文