-

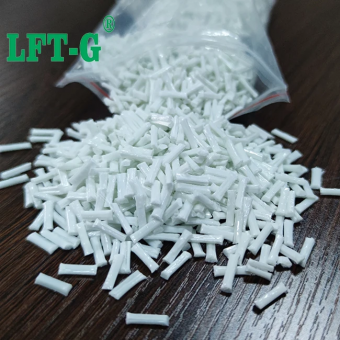

LFT Polyamide 66 high performance long carbon fiber reinforcementPolyamide 66 roving carbon fiber Nylon black color with heat resistance

- Long carbon fiber enhance pellets

- Roving carbon fiber PA66 instead metal and steel

- Nylon66 composite granules for injection

- High quality PA66 long fiber composite、

- Polyamide long fiber composite

- Virgin plastic PA6 LCF40 for car parts

Tags :

-

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinPP material Polypropylene, PP for short, is a polymer of propylene by adding polymerization. White waxy material, transparent and light in appearance. Polypropylene is a thermoplastic synthetic resin with excellent properties. It is a colorless translucent thermoplastic lightweight general plastic with chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear-resisting machining properties. PP-LGF material PP plus glass fiber is by adding glass fiber reinforced PP material, due to the addition of glass fiber, limited the mutual movement between polymer chains of PP plastic, therefore, the shrinkage rate of glass fiber reinforced PP (PP plus glass fiber) decreases, rigidity, impact resistance, tensile strength, compression strength, bending strength and flame retardant are improved. The mechanical properties of PP plus glass fiber specifically, tensile strength reached 65MPa--90MPa, bending strength reached 70MPa--20MPa, bending modulus reached 3000MPa--4500MPa, such mechanical strength can be completely comparable with ABS and enhanced ABS products, and more heat resistant. Generally, the heat resistance temperature of ABS and reinforced ABS is between 80℃--98℃, and the heat resistance temperature of glass fiber reinforced PP material can reach 135℃--145℃, and even 150 degrees can withstand more than 1000 hours. Compared with SGF(Short Glass Fiber) TDS for reference only Application of PP-Long glass fiber PP filling long glass fiber material, can be used to make refrigerators, air conditioning and other refrigeration machines in the axial flow fan and fan. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high mechanical performance requirements, used for rice cooker base and handle, electronic microwave oven and other places with high temperature resistance requirements, generally speaking, most glass fiber reinforced PP material is used in the structural parts of the product, is a kind of structural engineering materials. Cases Washing machine parts Automobile front end parts Scooter parts Frequently asked questions 1. Does long glass fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. 2. After long glass fiber reinforced, glass fiber can enter the surface of the plastic product during injection molding process, so that the surface of the product become rough and floating fiber. How to make the surface of the material smoothly? A. During injection molding process need to ensure that the plastic particles are well plasticized and dispersed, also ensure that the drying of plastic particles have no moisture removal, mold temperature adjustment to the appropriate temperature, mold surface is polished in place. 3. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products,

- long fibre reinforced thermoplastics

- long fiber compounds pp

- pp lgf40

- long glass fiber polypropylene

- long fiber composite PP granules

- PP LFT Compounds polymers

Tags :

-

LFT Polyamide 66 high performance Long Carbon Fiber ReinforcementPA66 carbon fiber conductive plastic reinforced nylon plastic material, which combines the electrical conductivity of metal (a voltage applied to both ends of the material, through the material through the current) and the various properties of plastic (that is, material molecules are composed of many small, repeated structural units).Density (g/cm3) : 1.2 ~ 1.7, conductive anti-static plastic shielding efficiency (30MHz-10GHz) : 60-85dB;, mainly used in electronics, integrated circuit packaging, electromagnetic shielding and other fields.It is an important type of conductive polymer materials.Conductive anti-static material Semi-conductive shielding material used in medium and high voltage cables.Conductive plastic is a kind of functional polymer material which mixes resin and conductive material and is processed in the way of plastic.Conductive anti-static plastic product density is low, the weight is reduced by 50%;Bending modulus (MPa) : 2400 ~ 6000. With the increase of carbon fiber content, the tensile strength, flexural strength and flexural elastic modulus of the composites all increase.The impact strength of the cantilever beam increases first and then decreases, and the impact strength reaches its maximum value when the carbon fiber mass fraction is 30%, which is. The reason is that when the fiber content is relatively large, the fracture stress and its energy threshold increase, and the absorption methods such as elongation of fracture path caused by avoiding fiber, demonding of fiber-matrix interface and fiber pull-out are added, while the internal notching effect of fiber increases slowly, thus increasing the impact strength.When the mass fraction of carbon fiber is more than 30%, the internal notching effect of carbon fiber increases with the increase of carbon fiber content, and the impact strength decreases. For more technical questions, please contact us:+ 86 139 5009 5727 WEB:www.lft-g.comview more

-

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinPP material Polypropylene, PP for short, is a polymer of propylene by adding polymerization. White waxy material, transparent and light in appearance. Polypropylene is a thermoplastic synthetic resin with excellent properties. It is a colorless translucent thermoplastic lightweight general plastic with chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear-resisting machining properties. PP-LGF material PP plus glass fiber is by adding glass fiber reinforced PP material, due to the addition of glass fiber, limited the mutual movement between polymer chains of PP plastic, therefore, the shrinkage rate of glass fiber reinforced PP (PP plus glass fiber) decreases, rigidity, impact resistance, tensile strength, compression strength, bending strength and flame retardant are improved. The mechanical properties of PP plus glass fiber specifically, tensile strength reached 65MPa--90MPa, bending strength reached 70MPa--20MPa, bending modulus reached 3000MPa--4500MPa, such mechanical strength can be completely comparable with ABS and enhanced ABS products, and more heat resistant. Generally, the heat resistance temperature of ABS and reinforced ABS is between 80℃--98℃, and the heat resistance temperature of glass fiber reinforced PP material can reach 135℃--145℃, and even 150 degrees can withstand more than 1000 hours. Compared with SGF(Short Glass Fiber) TDS for reference only Application of PP-Long glass fiber PP filling long glass fiber material, can be used to make refrigerators, air conditioning and other refrigeration machines in the axial flow fan and fan. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high mechanical performance requirements, used for rice cooker base and handle, electronic microwave oven and other places with high temperature resistance requirements, generally speaking, most glass fiber reinforced PP material is used in the structural parts of the product, is a kind of structural engineering materials. Cases Washing machine parts Automobile front end parts Scooter parts Frequently asked questions 1. Does long glass fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. 2. After long glass fiber reinforced, glass fiber can enter the surface of the plastic product during injection molding process, so that the surface of the product become rough and floating fiber. How to make the surface of the material smoothly? A. During injection molding process need to ensure that the plastic particles are well plasticized and dispersed, also ensure that the drying of plastic particles have no moisture removal, mold temperature adjustment to the appropriate temperature, mold surface is polished in place. 3. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products,view more

-

LFT Polypropylene PP filling long glass fiber 20%-60% high performance thermoplastic resinPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.view more

-

LFT Long Fiber Reinforced Nylon 66 High Strength CompoundsLFT long glass fiber reinforced PA66 material offers exceptional strength, impact resistance, and dimensional stability. With its superior mechanical properties, it is ideal for high-performance applications in automotive, electronics, and industrial components, providing durability and long-term reliability.

- Advanced Reinforced Thermoplastics

- Long Fiber Reinforced Polymers (LFRP)

- Long Fiber Composite Materials for Power Tools

- Injection Molding Long Fiber Materials

- PP/PA Reinforced Composite Materials

- Durable Composite Materials for Electronics

Tags :

-

LFT Long Fiber Reinforced Polyphenylene Sulfide Compounds Flame RetardantLFT®PPS-NA-LGF is glass reinforced PPS compound, which is filled with glass fiber based on the PPS resin. The characteristic of PPS compounds includes good mechanical properties, high rigidity, high creep resistance, high temperature resistance, flame resistance, chemical resistance, excellent electrical insulation properties, arc resistance, low water absorption, low mold shrinkage, easy processing, good dimensional stability, and radiation resistance.

- PPS Long Fiber Composite

- PPS Glass Fiber for Industrial Use

- PPS High Strength Materials

- PPS Thermoplastic for High-Temperature

- Long Glass Fiber Reinforced PPS

- Polyphenylene Sulfide High Performance Plastics

Tags :

-

LFT Long Glass Fiber Reinforced PBT Compounds Injection MoldingPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- High-Performance PBT Materials

- PBT Composite Materials for Industrial Applications

- PBT Thermoplastic for High-Temperature Parts

- PBT Long Glass Fiber for Manufacturing

- High-Strength PBT Long Fiber Composites

- Sustainable PBT Thermoplastics

Tags :

-

Advanced LGF Polyamide 6 Nylon for Structural ApplicationsOur PA6 Long Glass Fiber Reinforced Material is engineered to deliver exceptional strength, thermal stability, and impact resistance—making it the ideal alternative to metal for lightweight, high-performance components across multiple industries.

- nylon pa6 gf30

- nylon pa6 plastic material

- long fiber composites

- gfrp price per kg

- nylon 6 gf30 density

- long fiber thermoplastics

Tags :

-

New Materials LGF Polyamide 66 Nylon for Structural ApplicationsOur PA66 Long Glass Fiber Reinforced Material is a high-performance thermoplastic composite developed for applications demanding superior mechanical strength, dimensional stability, and heat resistance. Ideal for metal replacement and high-load structural components.view more

-

High Toughness Copo Polypropylene Carbon Fiber Filled Thermoplastic PelletsCombining the flexibility of Polypropylene and the properties of carbon fiber, PP-CF Compound material increases performance and brings reliability to the market.

- metal replacement solutions

- types of fibers in composite materials

- carbon reinforced plastic

- copolymer vs homopolymer polypropylene

- pp cf30

Tags :

-

High Performance Long Fiber ABS Lightweight Metal Replacement SolutionGlass fiber reinforced ABS modified plastics have many advantages, including excellent strength and stiffness, excellent heat resistance, good chemical resistance, low water absorption, good electrical insulation and stable performance. These advantages make it have a wide range of application prospects in many fields, and can meet the needs of different industries for high-performance materials.

- Reinforced ABS plastic

- High-performance plastic compounds

- Automotive ABS plastic parts

- Industrial ABS components

- ABS GF

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文