-

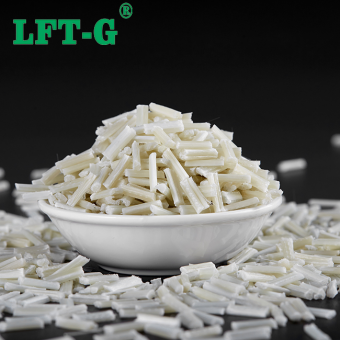

LFT-G brand high strength PBT reinforced plastic Long Glass Fiber filled injection grade compounds best pricePBT materials Polybutylene terephthalate (PBT) is a thermoplastic polyester and one of the top five engineering plastics. PBT has excellent overall performance, is one of the toughest engineering plastics, and has high dimensional stability, good chemical resistance, excellent electrical insulation, good mechanical properties and elasticity, low water absorption, etc. PBT filling Long glass fiber compounds PBT (polybutylene terephthalate) is a polyester-based plastic, while glass fiber is a reinforcing material that is usually added to plastics in fiber form to enhance their mechanical properties. When PBT is combined with glass fibers, the following effects occur: 1. Enhanced strength and stiffness: glass fiber has excellent strength and stiffness, and adding it to PBT can significantly increase the mechanical properties of the plastic. This makes the material of PBT with glass fiber more strong and rigid when it is subjected to force or stress, and less likely to deform or break. 2. Improve heat resistance: glass fiber has a high melting point and good heat resistance performance. When glass fiber is added to PBT, it can improve the heat resistance of PBT, so that it can keep better performance at higher temperature and prevent softening or melting. 3. Improve corrosion resistance: Glass fiber has excellent corrosion resistance, and adding it to PBT can improve its resistance to chemicals, solvents and other corrosive media. This makes PBT with glass fiber have longer service life in some special environments. 4. Improve insulation performance: PBT itself has good insulation performance, and the addition of glass fiber further improves the insulation performance of PBT material. This makes the PBT with glass fiber more suitable for electrical and electronic applications, which can effectively isolate the current and reduce leakage and electromagnetic interference. All in all, PBT with glass fiber can enhance the mechanical properties, heat resistance, corrosion resistance and insulation properties of plastics, making them more widely used in various applications. However, the performance of the material may vary depending on the specific glass fiber content and the addition process. Fiber specification Grade Fiber specification Characteristics Application Length Color Package General grade 20%-60% High toughness, Low warpage Electronic appliances, mechanical parts, etc. About 12mm, or customzied Natural color, or customized 25kg/bag The difference between LGF & SGF Short glass fiber particles: Size size is about 3-4mm, length to width ratio 50-250 Long glass fiber particles: Size is about 10-12mm, aspect ratio >400 In addition, the distribution of glass fiber in the two kinds of particles is also different. Compared with SGF, the rigidity, strength and modulus of LGF have been improved, especially the notched impact performance has got a qualitative leap. Application Datasheet for reference About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- PBT reisn composite lgf 30

- long glass fiber reinforced pbt for auto parts

- virgin white pbt can be recycled lgf

- thermoplastic plastic pbt lft

- high performance pbt with filler lgf

- PBT composite plastic

Tags :

-

LFT-G high performance PA6 Polyamide6 compounds long glass fiber instead metal original color sample availablePolyamide 66 plastic PA66 melting point 260~265℃, glass transition temperature (dry state) is 50℃. Density is 1.13~1.16 g/cm3. PA66 has low water absorption, excellent dimensional stability and high rigidity. Higher melting point, can be used for a long time in harsh environments, in a wide range of temperatures can still maintain sufficient stress, continuous use temperature of 105 ℃. Long glass fiber reinforced composite Glass fiber reinforced plastic is based on the original pure plastic, filling glass fibers and other additives, so as to improve the scope of use of the material. Generally speaking, most of the glass fiber reinforced materials are used in the structural parts of the products, which is a kind of structural engineering materials, such as: PP, ABS, PA66, PA6, TPU, PPA, PBT, PEEK, PBT, PPS and so on. Advantages 1)After glass fiber reinforcement, glass fiber is a high temperature resistant material, therefore, the heat-resistant temperature of reinforced plastics is much higher than before without glass fiber, especially nylon plastics. 2)After the glass fiber reinforcement, due to the addition of glass fiber, the plastic polymer chain is restricted to move with each other, therefore, the shrinkage of reinforced plastics decreases a lot, and the rigidity is greatly improved. 3)After glass fiber reinforced, the reinforced plastic will not stress cracking, at the same time, the impact resistance of the plastic improves a lot. 4)After the glass fiber reinforcement, the glass fiber is a high strength material, which also greatly improves the strength of the plastic, such as: tensile strength, compression strength, bending strength, improve a lot. 5)After glass fiber reinforcement, due to the addition of glass fiber and other additives, the combustion performance of the reinforced plastics decreases a lot, most of the materials can not be ignited, it is a kind of flame-retardant material. Datasheet for reference Applications PA66's comprehensive performance is good, with high strength, good rigidity, impact resistance, oil and chemical resistance, abrasion resistance and self-lubricating advantages, especially hardness, rigidity, heat resistance and creep performance is better. Datails Grade Fiber specification Main characteristics Applications General grade 20%-60% high toughness (especially at low temperatures), excellent creep and fatigue resistance, low warpage Automobiles, electronic and electrical appliances, sports equipment, power tools, high-speed rail parts, etc. Toughen resistance grade 20%-50% high impact strength, light texture Automobiles, electronic appliances, sports equipment, power tools, tool handles, high-speed rail parts, gears, etc. Lab & Factory About company Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- PA66 Nylon pellets reinforced plastic

- polyamide 6 engineering plastics lgf

- Low warpage modified PA6 LGRF

- injection mold PA66 auto parts polymers

- Nylon composite pellets Polymer granules

- long glass fiber reinforced plastic pa66

Tags :

-

Xiamen LFT-G ABS plastic raw material filled Long glass fiber granules polymer injection moldedabs v0 plastic raw material abs granules polymer lgf40 which one is made in ourself factory.

- ABS resin long glass fiber reinforced thermoplastic

- ABS pellets extrusion molding

- ABS nylon best price supplier

- ABS injection molding pellets composites

- ABS Composite Pellets low warpage

- ABS material data sheet

Tags :

-

Xiamen LFT-G High Density Polyethylene HDPE LGF60 Fill Long Glass Fiber Composite materialsProduct Name:HDPE LGF60, Polyethylene Long Glass Fiber Reinforced 60% Form: UV resistant and aging resistant Advantage: High quality and low cost

- HDPE LGF60 recycled plastic

- LFT HDPE Composite pure plastic virgin grade

- High Density Polyethylene LGF60

- HDPE Long Glass Fiber Reinforced Plastic

- Lightweight HDPE GF60 application

- HDPE Glass Fiber Compounds

Tags :

-

Xiamen LFT-G PLA Polylactic acid composite long glass fiber filling thermoplastic resin original colorPLA PLA (polylactic acid) is also known as polylactic acid, the production process of polylactic acid is pollution-free, and the product can be biodegradable to achieve recycling in nature, so it is an ideal green polymer material, and one of the representatives of biodegradable plastics. The structure of PLA has important influence on its heat resistance, toughness, mechanical strength, degradability and biocompatibility. The influence on heat resistance is mainly discussed below. There is only one submethylene on the main chain of PLA molecule, the molecular chain has a spiral structure, and its activity is poor. As a result, the PLA after injection molding almost does not crystallize due to slow crystallization speed, so the heat resistance of the product is poor. During hot processing, the ester bond is partially broken to produce terminal carboxyl group, which plays an autocatalytic degradation effect on the thermal degradation of PLA. LGF reinforced PLA The rigidity of the fiber makes it play the role of skeleton support in the polymer matrix. When the polymer is heated, the movement of the chain segment is limited, thus improving the heat resistance of the material. At present, the fibers that can be used for enhancement modification of PLA include natural plant fiber (sisal, flax, linen, bamboo, coconut, wood fiber, etc.), natural animal fiber (silk, etc.), mineral fiber (basalt fiber, etc.), and chemical fiber (carbon fiber, glass fiber, etc.). Among these fibers, carbon fiber and glass fiber are widely used for their high strength and high modulus. Natural plant fiber has been widely studied because of its wide source, degradability and improved thermal and mechanical properties of composites. Modified natural fiber and modified inorganic fiber (glass fiber or carbon fiber) were mixed into the PLA matrix to prepare two kinds of fiber reinforced PLA composites. The test results show that the Vica softening temperature of the composites exceeds 140℃. Compared with Short fiber(SGF) Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Injection molding Lab Warehouse Certification Xiamen LFT composite plastic Co., Ltd Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- PLA composite plastic can be recycled

- polyactic acid materials injection molding

- modified pla compounds

- pla long glass fiber reinforced plastic resin

- long glass fiber filling pla sample available

- lft-g pla lgf low warpage

Tags :

-

High strength PA12 nylon12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.

- Nylon12 filling long glass fiber reinforced plastic

- Durability high mechanical properties

- Photovoltaic industry compounds

- Injection grade thermoplastic resin

- 24h service customized plastic instead metal

- Supplier price good price pa6 composites

Tags :

-

LFT-G Polyamide 66 with addition long glass fiber 20%-60% reinforced plastic as a replacement for metalWhat is Polyamide 66 materials? PA66, abbreviation of Polyamide 66, chemical name polyhexanediylhexanediamine, commonly known as nylon 66. It is a colorless transparent semi-crystalline thermoplastic polymer, widely used in automotive, electrical and electronic appliances, mechanical instruments and meters, industrial parts and other industries. However, due to the high water absorption, poor acid resistance, low impact strength in dry state and low temperature, and easy to deform after absorbing water, which affects the dimensional stability of the products, the scope of its application has been limited to a certain extent. In order to improve the above shortcomings, expand its field of application, and better meet the requirements for the use of performance, people use a variety of methods to modify PA66, in order to improve the impact, heat deformation, molding and processing performance and chemical corrosion resistance of PA66 plastic. As the specific strength and Young's modulus of glass fiber (GF) is 10-20 times larger than PA66, the coefficient of linear expansion is about 1/20 of PA66, the water absorption rate is close to zero, and there is good heat and chemical resistance, etc., so the glass fiber filling is the most commonly used means of enhancement and modification of PA66. Polyamide 66 fillin long glass fiber compounds Why do we use LFT plastics instead of metal? Many components that are currently manufactured in metal can be produced at lower cost and lower weight in high strength plastics. Compared to metals, plastics offer a number of significant advantages: • Faster production cycles • Lower investment in equipment and tooling • Elimination of finishing operations, such as machining or painting • No corrosion problems • Tighter tolerances • Easier assembly What is the difference between Long glass fiber and Stardard glass fiber? Long glass fiber (LGF) typically contain glass fibers with lengths of 10 to 12 mm, versus 0.7-mm fibers in standard glass-reinforced compounds. In the composite material made of fibers is sheared or pulled, the fibers are pulled out from the matrix, such a pulling process is conducive to the absorption of energy provided by the loading, the longer the fibers are within a certain length, the greater the absorption of energy, and the more significant its strength. And in the same volume amount, due to the longer the single fiber, the fewer the number of fiber roots, the less stress concentration generated at the fiber end, the more difficult the destruction of the material. From the results of practical application feedback, the various properties of long glass fiber reinforced thermoplastic composites are more excellent than Standard glass fiber. In addition, glass fiber reinforced composites in the friction process, the fiber body plays an important role in lubrication, long glass fiber can be much more sustainable, stable lubrication, so the coefficient of friction is lower, less wear, and the formation of the abrasive debris is finer. Because of these advantages, long glass-fiber reinforced thermoplastic composites perform better in real-world applications without fear of high frequencies and high loads. What is the advantages of Polyamide 66? Nylon 6/6 is composed of a molecular structure of higher order than Nylon 6, heightening Nylon 6’s positive characteristics: higher tensile strength and stiffness, better dimensional stability, and a higher melting point. Nylon 6/6 has a high lubricity and resistance to hydrocarbons; and exceptionally balanced strength, ductility, and heat resistance. As strong as it is independently, adding fillers, fibers, lubricants, and impact modifiers can increase Nylon 6/6’s strength times five and stiffness times ten. TDS of 30% long stand fiber glass reinforced Polyamide 6.6 All TDS with 20%-60% fiber specification, please aks technologists What are the applications of Nylon 66 filling long stand fiber glass pellets? Frequently asked questions Q. Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. Q. Using a long fiber reinforced thermoplastic material, will it block the die hole due to the long length of the fiber or not? A. When using long glass fiber or long carbon fiber, it is necessary to evaluate whether the product is suitable for LFT-G. If the product is too small or the dispensing is not suitable for long fiber materials. The long fiber itself has requirements for mold nozzle. Q. How to choose the rei...

- engineering thermoplastics PA66

- long glass fiber reinforced thermoplastic resin pa66

- heat deflection temperature pa66 gf

- Nylon 66 comounds more dystaline

- injection molded high stiffness and tensile

- gf filled plastic pa66 natural color

Tags :

-

Xiamen LFT high strength PBT reinforced plastic Long Glass Fiber filled compoundsPBT materials Polybutylene terephthalate (PBT) is a thermoplastic polyester and one of the top five engineering plastics. PBT has excellent overall performance, is one of the toughest engineering plastics, and has high dimensional stability, good chemical resistance, excellent electrical insulation, good mechanical properties and elasticity, low water absorption, etc. PBT filling Long glass fiber compounds PBT (polybutylene terephthalate) is a polyester-based plastic, while glass fiber is a reinforcing material that is usually added to plastics in fiber form to enhance their mechanical properties. When PBT is combined with glass fibers, the following effects occur: 1. Enhanced strength and stiffness: glass fiber has excellent strength and stiffness, and adding it to PBT can significantly increase the mechanical properties of the plastic. This makes the material of PBT with glass fiber more strong and rigid when it is subjected to force or stress, and less likely to deform or break. 2. Improve heat resistance: glass fiber has a high melting point and good heat resistance performance. When glass fiber is added to PBT, it can improve the heat resistance of PBT, so that it can keep better performance at higher temperature and prevent softening or melting. 3. Improve corrosion resistance: Glass fiber has excellent corrosion resistance, and adding it to PBT can improve its resistance to chemicals, solvents and other corrosive media. This makes PBT with glass fiber have longer service life in some special environments. 4. Improve insulation performance: PBT itself has good insulation performance, and the addition of glass fiber further improves the insulation performance of PBT material. This makes the PBT with glass fiber more suitable for electrical and electronic applications, which can effectively isolate the current and reduce leakage and electromagnetic interference. All in all, PBT with glass fiber can enhance the mechanical properties, heat resistance, corrosion resistance and insulation properties of plastics, making them more widely used in various applications. However, the performance of the material may vary depending on the specific glass fiber content and the addition process. Fiber specification Grade Fiber specification Characteristics Application Length Color Package General grade 20%-60% High toughness, Low warpage Electronic appliances, mechanical parts, etc. About 12mm, or customzied Natural color, or customized 25kg/bag The difference between LGF & SGF Short glass fiber particles: Size size is about 3-4mm, length to width ratio 50-250 Long glass fiber particles: Size is about 10-12mm, aspect ratio >400 In addition, the distribution of glass fiber in the two kinds of particles is also different. Compared with SGF, the rigidity, strength and modulus of LGF have been improved, especially the notched impact performance has got a qualitative leap. Application Datasheet for reference About us Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- PBT reisn composite lgf 30 best price

- thermoplastic plastic pbt lft made in China whole sell

- PBT composite plastic manufacturert direct sell

Tags :

-

Xiamen LFT-G TPU Thermoplastic Urethane filling long glass fiber compounds plasticWhat is TPU? TPU(Thermoplastic polyurethanes) name is elastomer rubber. It is mainly divided into polyester type and polyether type, its hardness range is wide (60HA-85HD), wear resistance, oil resistance, transparent, good elasticity, in daily necessities, sports goods, toys, decorative materials and other fields are widely used, halogen-free flame retardant TPU can also replace soft PVC to meet more and more fields of environmental protection requirements. The so-called elastic body refers to the glass transition temperature is lower than the room temperature, elongation at break >50%, the external force removed after the good recovery polymer material. Polyurethane elastomer is a special category of elastomer, polyurethane elastomer hardness range is very wide, performance range is very wide, so polyurethane elastomer is a kind of polymer material between rubber and plastic. It can be heated plasticized and has little or no crosslinking in chemical structure. Its molecules are basically linear, but there is some physical crosslinking. This type of polyurethane is called a TPU. Why filling long glass fiber? Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network. Performance is preserved in a wide range of environments. Compared with Short glass fiber Application of TPU filling Long Glass Fiber compounds Car doors and windows, Safty toe, Mechanical parts, Pneumatic nail gun boxes, Professional power tools, Nut and bolts, Etc. About Xiamen LFT Composite Plastic Co., Ltd. Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) and Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in legnth. The company's long-fiber continuous infiltration reinofrced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents. Quality Management System ISO9001&16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testing

- tpu lft long glass fiber composites polymers

- long fibre reinforced thermoplastics

- glass fiber reinforced plastics granules

- long glass fiber TPU made in China

- long fiber composite TPU granules

- long glass fiber reinforced TPU lft shoes

Tags :

-

Xiamen LFT Polyamide6 compounds with long glass fiber instead metal high strengthWhat is Polyamide 66 plastic? PA66 melting point 260~265℃, glass transition temperature (dry state) is 50℃. Density is 1.13~1.16 g/cm3. PA66 has low water absorption, excellent dimensional stability and high rigidity. Higher melting point, can be used for a long time in harsh environments, in a wide range of temperatures can still maintain sufficient stress, continuous use temperature of 105 ℃. Long glass fiber reinforced composite Glass fiber reinforced plastic is based on the original pure plastic, filling glass fibers and other additives, so as to improve the scope of use of the material. Generally speaking, most of the glass fiber reinforced materials are used in the structural parts of the products, which is a kind of structural engineering materials, such as: PP, ABS, PA66, PA6, TPU, PPA, PBT, PEEK, PBT, PPS and so on. Advantages 1)After glass fiber reinforcement, glass fiber is a high temperature resistant material, therefore, the heat-resistant temperature of reinforced plastics is much higher than before without glass fiber, especially nylon plastics. 2)After the glass fiber reinforcement, due to the addition of glass fiber, the plastic polymer chain is restricted to move with each other, therefore, the shrinkage of reinforced plastics decreases a lot, and the rigidity is greatly improved. 3)After glass fiber reinforced, the reinforced plastic will not stress cracking, at the same time, the impact resistance of the plastic improves a lot. 4)After the glass fiber reinforcement, the glass fiber is a high strength material, which also greatly improves the strength of the plastic, such as: tensile strength, compression strength, bending strength, improve a lot. 5)After glass fiber reinforcement, due to the addition of glass fiber and other additives, the combustion performance of the reinforced plastics decreases a lot, most of the materials can not be ignited, it is a kind of flame-retardant material. Datasheet for reference Applications PA66's comprehensive performance is good, with high strength, good rigidity, impact resistance, oil and chemical resistance, abrasion resistance and self-lubricating advantages, especially hardness, rigidity, heat resistance and creep performance is better. Datails Grade Fiber specification Main characteristics Applications General grade 20%-60% high toughness (especially at low temperatures), excellent creep and fatigue resistance, low warpage Automobiles, electronic and electrical appliances, sports equipment, power tools, high-speed rail parts, etc. Toughen resistance grade 20%-50% high impact strength, light texture Automobiles, electronic appliances, sports equipment, power tools, tool handles, high-speed rail parts, gears, etc. Lab & Factory About company Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.view more

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.

- Compound plastic materials PP resin

- Polypropylene with long glass fiber

- pp filling glass fiber reinforced thermoplastic

- High strength modified material

- pp lgf lft PP GF30 high rigidity

- long glass fiber reinforced polypropylene

Tags :

-

Xiamen LFT high temperature resistance Polyphenylene sulfide PPS filled long glass fiber polymerPolyphenylene sulfide PPS plastic (polyphenylene sulfide) is a special engineering plastic with excellent comprehensive performance, high strength, the sound of metal, and the material is as hard as metal. It also has the characteristics of high temperature resistance, cold resistance, acid and alkali resistance, wear resistance, flame retardant V0, low warping and excellent electrical properties. Compared with metal, PPS material products are light in weight, which is particularly important for mechanical equipment requiring self-weight reduction, such as vehicles, ships and aircraft. PPS material strength is high, compared with the weight of metal, PPS strength is much higher than the general metal, is the highest strength of existing structural materials. PPS material has good chemical stability, and has good corrosion resistance to general acids, alkalis and other chemicals. The electrical properties of PPS materials are very outstanding, in the high temperature, high humidity, high frequency environment, high volume resistivity and insulation resistance remain unchanged, is an excellent insulation material. PPS material has good wear resistance and can be used to manufacture a variety of self-lubricating bearings, gears and seals. PPS material molding processing is convenient, products can often be formed at one time, and metal products always have to go through several, more than a dozen, or even dozens of processes to complete the processing. Long glass fiber compounds "Center Fill" is LFT compounds that are obtained through our technology by charging glass fiber rovings composed of thousands of filaments into an impregnation process and impregnating the glass fibers uniformly with molten thermoplastic resin and then cutting the resultant product into pellets. Significantly improved impact resistance Increased stiffness and strength Good heat resistance Improved creep and wear characteristics Reduced the degree of warpage and deformation Reinforced properties of recycled crystalline and non-crystalline resins Details Name Fiber content Color Length MOQ TDS FOB Price Delivery polyphenylene sulfide filled long glass fiber polymer 20%-60% Natural color/Customized 6-25mm 25KG/Bag Contact us for TDS USD8.8-11.1/KG By ship or air Company profile Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. Other materials you may interested PA66-NA-LGF PPA-NA-LCF PA12-NA-LGF

- Exceptional mechanical strength Polyphenylene sulfide plastic

- LFT PPS long glass fiber reinforced thermoplastic resin pellets

- PPS plastic granules high strength made in China

- PPS can be customized long cut fiber filament

- hot sell light weight plastic instead metal and steel

- engineering used plastic PPS good appearance gfrp

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文