-

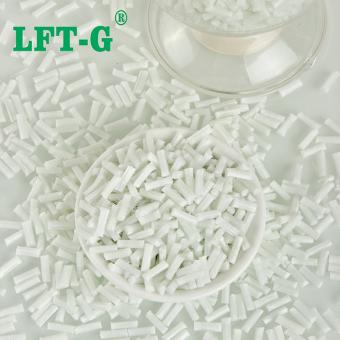

LFT-G brand Polyamide6 nylon6 filling long glass fiber40 orginal color for automotive partsWhat is PA6 plastic? polyamide (PA), usually called Nylon, is a hetero-chain polymer containing amide group (-NHCo -) in the main chain. It can be divided into aliphatic group and aromatic group. It is the earliest developed and the most used thermoplastic engineering material. Polyamide main chain contains many repeated amide group, used as a plastic called nylon, used as a synthetic fiber called nylon. A variety of different polyamides can be prepared according to the number of carbon atoms contained in binary amines and dibasic acids or amino acids. At present, there are dozens of polyamides, among which polyamide-6, polyamide-66 and polyamide-610 are the most widely used. Polyamide-6 is an aliphatic polyamide, with light weight, strong strength, wear resistance, weak acid and alkali resistance and some organic solvents, easy molding and processing and other excellent properties, widely used in fiber, engineering plastics and thin films and other fields, but PA6 molecular chain segment contains strong polarity amide groups, easy to form hydrogen bonds with water molecules, The product has the disadvantages of large water absorption, poor dimensional stability, low impact strength in dry state and low temperature, strong acid and alkali resistance. Advantages of nylon 6: High mechanical strength, good toughness, high tensile and compressive strength. Outstanding fatigue resistance, the parts after repeated bending can still maintain the original mechanical strength. High softening point, heat resistant. Smooth surface, small friction coefficient, wear-resistant. Corrosion resistance, very resistant to alkali and most salts, also resistant to weak acids, oil, gasoline, aromatic compounds and general solvents, aromatic compounds are inert, but not resistant to strong acids and oxidants. It can resist the corrosion of gasoline, oil, fat, alcohol, alkaline and so on, and has good anti-aging ability. It is self-extinguishing, non-toxic, odorless, good weather resistance, inert to biological erosion, and has good antibacterial and mildew resistance. Has excellent electrical performance, good electrical insulation, nylon volume resistance is high, high breakdown voltage resistance, in dry environment, can work frequency insulation material, even in high humidity environment still has good electrical insulation. Light weight, easy dyeing, easy forming, because of low melting viscosity, can flow quickly. Disadvantages of Nylon 6: Easy to absorb water, water absorption, saturated water can reach more than 3%. Poor light resistance, in the long-term high temperature environment will oxidize with oxygen in the air, the color turns brown at the beginning, and the subsequent surface is broken and cracked. Injection molding technology requirements more strict, the existence of trace moisture will cause great damage to the quality of molding; The dimensional stability of the product is difficult to control because of thermal expansion. The existence of sharp Angle in the product will lead to stress concentration and reduce the mechanical strength; If the wall thickness is not uniform, it will lead to the distortion and deformation of the parts. High precision of equipment is required in post-processing. Will absorb water, alcohol and swelling, not resistant to strong acid and oxidant, can not be used as acid-resistant materials. Why filling Long Glass Fiber? PA6 has excellent properties such as light weight, strong strength, abrasion resistance, weak acid and alkali resistance and some organic solvents, and easy molding and processing. It is widely used in the fields of fibers, engineering plastics and films. However, the molecular chain segment of PA6 contains highly polar amide groups, which are easy to form hydrogen bonds with water molecules. The product has the disadvantages of large water absorption, poor dimensional stability, low impact strength in dry state and low temperature, strong acid and alkali resistance. With the development of science and technology and the improvement of life quality, the defects in some properties of traditional PA6 materials have limited its development in some fields. In order to improve the performance of PA6 and expand its application field, PA6 should be modified. Filling enhancement modification is a common method for physical modification of PA6. It refers to the modification of PA6 by adding fillers such as glass fiber and carbon fiber into the matrix to significantly improve the mechanical properties, flame retardant properties, thermal conductivity and dimensional stability of the material. What is application of PA6-LGF? Modified section of 30% long glass fiber reinforced PA6 is the ideal material for processing power tool shell, power tool parts, engineering machinery parts and automobile parts. Its mechanical properties, dimensional stability, heat resistance and aging resistance have been significantly improved. The fatigue resistance strength is 2.5 times that of unenha...

- Polyamide 6 composite properties

- lgf thermoplastic resin good price

- High impact PA6 instead metal plastic

- injection molding plastic gf30 filter

- pa6 filling long glass fiber customized

- Reinforced plastic lightweight compounds

Tags :

-

Xiamen LFT-G High Density Polyethylene HDPE LGF60 Fill Long Glass Fiber Composite materialsProduct Name:HDPE LGF60, Polyethylene Long Glass Fiber Reinforced 60% Form: UV resistant and aging resistant Advantage: High quality and low cost

- HDPE LGF60 recycled plastic

- LFT HDPE Composite pure plastic virgin grade

- High Density Polyethylene LGF60

- HDPE Long Glass Fiber Reinforced Plastic

- Lightweight HDPE GF60 application

- HDPE Glass Fiber Compounds

Tags :

-

Xiamen LFT-G PLA Polylactic acid composite long glass fiber filling thermoplastic resin original colorPLA PLA (polylactic acid) is also known as polylactic acid, the production process of polylactic acid is pollution-free, and the product can be biodegradable to achieve recycling in nature, so it is an ideal green polymer material, and one of the representatives of biodegradable plastics. The structure of PLA has important influence on its heat resistance, toughness, mechanical strength, degradability and biocompatibility. The influence on heat resistance is mainly discussed below. There is only one submethylene on the main chain of PLA molecule, the molecular chain has a spiral structure, and its activity is poor. As a result, the PLA after injection molding almost does not crystallize due to slow crystallization speed, so the heat resistance of the product is poor. During hot processing, the ester bond is partially broken to produce terminal carboxyl group, which plays an autocatalytic degradation effect on the thermal degradation of PLA. LGF reinforced PLA The rigidity of the fiber makes it play the role of skeleton support in the polymer matrix. When the polymer is heated, the movement of the chain segment is limited, thus improving the heat resistance of the material. At present, the fibers that can be used for enhancement modification of PLA include natural plant fiber (sisal, flax, linen, bamboo, coconut, wood fiber, etc.), natural animal fiber (silk, etc.), mineral fiber (basalt fiber, etc.), and chemical fiber (carbon fiber, glass fiber, etc.). Among these fibers, carbon fiber and glass fiber are widely used for their high strength and high modulus. Natural plant fiber has been widely studied because of its wide source, degradability and improved thermal and mechanical properties of composites. Modified natural fiber and modified inorganic fiber (glass fiber or carbon fiber) were mixed into the PLA matrix to prepare two kinds of fiber reinforced PLA composites. The test results show that the Vica softening temperature of the composites exceeds 140℃. Compared with Short fiber(SGF) Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Injection molding Lab Warehouse Certification Xiamen LFT composite plastic Co., Ltd Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- PLA composite plastic can be recycled

- polyactic acid materials injection molding

- modified pla compounds

- pla long glass fiber reinforced plastic resin

- long glass fiber filling pla sample available

- lft-g pla lgf low warpage

Tags :

-

High strength PA12 nylon12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.

- Nylon12 filling long glass fiber reinforced plastic

- Durability high mechanical properties

- Photovoltaic industry compounds

- Injection grade thermoplastic resin

- 24h service customized plastic instead metal

- Supplier price good price pa6 composites

Tags :

-

Xiamen LFT-G MXD6 meta-xylylene adipamide nylon Long glass fiber filling 30% high barrier propertiesWhat is MXD6? Conventional aliphatic nylon is easy to process but has strong water absorption and low glass conversion temperature. Although all-aromatic nylon has solved the shortcomings of aliphatic products to a large extent, the processing difficulty has increased exponentially. After 1972, Toyo Textile and Mitsubishi Gas Chemical synthesized a new kind of semi-aromatic nylon MXD6, which not only overcame the disadvantages of aliphatic and all-aromatic resins to a large extent, but also had some advantages of all-aromatic resins. It is widely used in packaging materials with high gas barrier and engineering structural materials. In summary, MXD6 has the following advantages: High strength and elastic modulus; The high glass transition temperature is 237℃ for Tm and 85℃ for Tg. Low water absorption and moisture permeability; Fast crystallization speed, easy to form and manufacture; Excellent gas barrier performance. Why add Long Glass Fiber? Long glass fiber reinforced composite can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace matal with plastic. Long Glass Fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanial properties of engineering internal skeleton network. Performance is preserved in a wide range of environments. MXD6 performance and application Compared with other materials, MXD6 has the advantages of high strength and elastic modulus, high glass transition temperature, low water absorption and moisture permeability, fast crystallization speed, convenient molding and manufacturing, excellent gas barrier properties, and can also be a good barrier to carbon dioxide and oxygen even under high humidity. In the end market, MXD6 is rarely used alone and is generally added to other polymers as a modified component. Materials containing MXD6 are mainly used in automotive and packaging fields. As an engineering plastic, MXD6 can replace the use of metal materials in the automotive industry, such as power tools, magnetic materials, automotive shell, chassis, girders, engine accessories, etc. We will offer you: 1) LFT & LFRT material technical parameters and leading edge design; 2) Mold front design and recommendations; 3)Provide technical support such as injection molding and extrusion molding. System Certification Quality Management System ISO9001/1949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testing

- New material MX-Nylon plastic

- Polycondensation product mxd6

- Crystalline polymer reinforced plastic

- Special nylon Polyxylylene

- Polyamide fibre made in China

- Long glass fiber composite

Tags :

-

Xiamen LFT-G MXD6 meta-xylylene adipamide nylon Long glass fiber filling 30% high barrier propertiesWhat is MXD6? Conventional aliphatic nylon is easy to process but has strong water absorption and low glass conversion temperature. Although all-aromatic nylon has solved the shortcomings of aliphatic products to a large extent, the processing difficulty has increased exponentially. After 1972, Toyo Textile and Mitsubishi Gas Chemical synthesized a new kind of semi-aromatic nylon MXD6, which not only overcame the disadvantages of aliphatic and all-aromatic resins to a large extent, but also had some advantages of all-aromatic resins. It is widely used in packaging materials with high gas barrier and engineering structural materials. In summary, MXD6 has the following advantages: High strength and elastic modulus; The high glass transition temperature is 237℃ for Tm and 85℃ for Tg. Low water absorption and moisture permeability; Fast crystallization speed, easy to form and manufacture; Excellent gas barrier performance. Why add Long Glass Fiber? Long glass fiber reinforced composite can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace matal with plastic. Long Glass Fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanial properties of engineering internal skeleton network. Performance is preserved in a wide range of environments. MXD6 performance and application Compared with other materials, MXD6 has the advantages of high strength and elastic modulus, high glass transition temperature, low water absorption and moisture permeability, fast crystallization speed, convenient molding and manufacturing, excellent gas barrier properties, and can also be a good barrier to carbon dioxide and oxygen even under high humidity. In the end market, MXD6 is rarely used alone and is generally added to other polymers as a modified component. Materials containing MXD6 are mainly used in automotive and packaging fields. As an engineering plastic, MXD6 can replace the use of metal materials in the automotive industry, such as power tools, magnetic materials, automotive shell, chassis, girders, engine accessories, etc. We will offer you: 1) LFT & LFRT material technical parameters and leading edge design; 2) Mold front design and recommendations; 3)Provide technical support such as injection molding and extrusion molding. System Certification Quality Management System ISO9001/1949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testingview more

-

LFT-G Polyamide 12 long carbon fiber filled modified nylon12 high impact resistance and toughnessLong carbon fiber Carbon fiber has many excellent properties, high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. But is there a way to reduce the price of carbon fiber? That is to mix it with relatively cheap nylon material to form a composite material with good performance and meet the requirements. In that case, there is no doubt that carbon fiber nylon will definitely have a place in the composite material. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness are also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF / PA) composites have developed rapidly in recent years. And for 3D printing using SLS technology is the most suitable technical means to achieve carbon fiber reinforced nylon. TDS for reference Application Our company Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- long fibre reinforced thermoplastics resin pa12

- carbon fiber reinforced plastics granules

- long carbon fiber reinforced pa12

- thermoplastic Polyamide 12 natural color with addition fiber

- wear resistance injection molding pa12 gf

- pa12 lcf for car parts

Tags :

-

Xiamen LFT-G HDPE filling long glass fiber high toughness stiffness modified pellets for shellHDPE Introduction High-density polyethylene is an opaque white waxy material, lighter than water, specific gravity of 0.941 ~ 0.960, soft and tough, but slightly harder than LDPE, but also slightly elongated, non-toxic, odorless. Flammable, can continue to burn after leaving the fire, the upper end of the flame is yellow, the lower end is blue, will melt when burning, there are liquid drops, no black smoke, at the same time, emitting the smell of paraffin wax when burning. Acid and alkali resistance, organic solvent resistance, excellent electrical insulation, low temperature, can still maintain a certain degree of toughness. Surface hardness, tensile strength, rigidity and other mechanical strength are higher than LDPE, close to PP, tougher than PP, but the surface finish is not as good as PP. Poor mechanical properties, poor air permeability, easy to deformation, easy to aging, easy to brittle, brittle than PP, easy stress cracking, low surface hardness, easy to scratch. Difficult to print, when printing, surface discharge treatment is required, can not be plated, and the surface is not glossy. HDPE-Long glass fiber Because of its high crystallinity, poor impact strength and environmental cracking resistance and other defects, limiting its scope of application, so a lot of toughening modification HDPE research work has been carried out at home and abroad. Our company has greatly improved the performance of HDPE through the way of co-blending modification. Long fiber reinforced thermoplastic composites are reinforced thermoplastics with fiber lengths greater than 10mm. The reinforcing fibers are mainly glass fibers, carbon fibers, etc. Depending on the type of resin with appropriate fiber surface treatment, better results can be achieved. The addition of fiber material to the resin can greatly improve the overall material performance. Fiber composites absorb external forces in three ways: fiber pullout, fiber breakage, and resin fracture. The increase of fiber length consumes more energy for fiber pull-out, which is beneficial to the improvement of impact strength; the end of fiber in the composite is often the initiation point of crack growth, and the small number of long fiber ends also makes the impact strength increase; the long fiber blends entangle, flip and bend each other when filling the mold, unlike the short fiber blends which are arranged in the flow direction, therefore, the long fiber blends molded products are better than the same molded parts of short fiber blends. Therefore, compared with the same molded parts of short fiber blends, the long fiber blends have higher isotropy, better straightness, less warpage, and therefore better dimensional stability; the heat deflection temperature of long fiber reinforced thermoplastics is also increased than that of short fiber blends. Therefore, long-fiber composites exhibit better performance than short-fiber composites, which can improve rigidity, compression strength, bending strength, and creep resistance. Process TDS for your reference Tests Certifications Quality Management System ISO9001/16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROSH testing Application We will provide technical supports according to your product's images. About us We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design ang recommendations. 3. Provide technical support such as injection molding and extrusion molding. Frequently asked questions Q: How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A: The selection of materials depend on the requirements of products. It is necessary to assess how much the content is reinforced and how much length is more appropriate, which are depending on the performance requirements of the products. Q: In addition to being suitable for injection molding, long fiber products can be extruded or other processes? A: LFT long glass fiber and long carbon fiber are mainly used for injection molding, and can also extrusion plate profile tube and mold edges a variety of thermoplastic molding methods. Q: The cost of long fiber products is higher than raw materials. Does it has a high recycling value? A: The thermoplastic LFT long fiber material can be recycled and reused very well.

- long glass fiber HDPE instead metal and steel

- long fibre reinforced thermoplastics

- glass fiber reinforced plastics granules

- LFT composite PE for pipe undergrund

- HDPE LGF sample available injection mold

- Glass fiber fill hdpe virgin grade

Tags :

-

Xiamen LFT-G PPS Polyphenylene sulfide composite long glass fiber thermoplastic original colorPPS information The resin matrix of thermoplastic composites involves general and special engineering plastics, and PPS is a typical representative of special engineering plastics, commonly known as "plastic gold". Performance advantages include the following aspects: excellent heat resistance, good mechanical properties, corrosion resistance, self-flame retardant up to UL94 V-0 level. Because PPS has the advantages of the above properties, and compared with other high performance thermoplastic engineering plastics and has the characteristics of easy processing, low cost, so it becomes an excellent resin matrix for manufacturing composite materials. PPS composite material PPS filling short glass fiber (SGF) composite material has the advantages of high strength, high heat resistance, flame retardant, easy processing, low cost, and has been applied in automotive, electronics, electrical, machinery, instruments, aviation, aerospace, military and other fields. PPS filling long glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, good product appearance and so on. It can be used in water heater impeller, pump shell, joint, valve, chemical pump impeller and shell, cooling water impeller and shell, household appliance parts and so on. What are the specific differences between short glass fiber (SGF) and long glass fiber (LGF) reinforced PPS composites? 1. Mechanical property analysis The reinforcement fiber added in the resin matrix can form a supporting skeleton, and the reinforcement fiber can effectively bear the external load when the composite is subjected to external force. At the same time, energy can be absorbed by fracture, deformation and other ways to improve the mechanical properties of resin. The tensile strength and bending strength of the composites are gradually increased by increasing the amount of glass fiber. The main reason is that when the glass fiber content increases, more glass fiber in the composite material can withstand the action of external force. Meanwhile, due to the increase in the number of glass fibers, the resin matrix between the glass fibers becomes thinner, which is more conducive to the construction of glass fiber reinforced frame. Therefore, with the increase of glass fiber content, more stress is transferred from resin to glass fiber under external load, which effectively improves the tensile and bending properties of composite materials. The tensile and bending properties of PPS/LGF composites are higher than those of PPS/SGF composites. When the glass fiber mass fraction is 30%, the tensile strength of PPS/SGF and PPS/LGF composites is 110MPa and 122MPa, respectively. The bending strength was 175MPa and 208MPa, respectively. The flexural elastic modulus were 8GPa and 9GPa, respectively. The tensile strength, bending strength and bending elastic modulus of PPS/LGF composites are increased by 11.0%, 18.9% and 11.3% compared with PPS/SGF composites, respectively. PPS/LGF composites have higher length retention rate of glass fiber. Under the condition of the same glass fiber content, the composites have stronger load resistance and better mechanical properties. When the glass fiber content is low, the impact strength of the composite decreases. The main reason is that the lower glass fiber content cannot form a good stress transfer network in the composite material, so that the glass fiber exists in the form of defects under the impact load of the composite material, resulting in the overall impact strength of the composite material is reduced. With the increase of the glass fiber content, the glass fiber in the composite can form an effective spatial network, and the reinforcement effect is greater than that of the glass fiber tip. Under the action of external load, the external load can be transferred to the reinforced fiber better, thus improving the overall performance of the composite. In the PPS/LGF system, the length of the glass fiber is longer and the spatial network is more dense. The reinforced glass fiber has greater bearing capacity and better impact strength. When the mass fraction of glass fiber is 30%, the impact strength of PPS/LGF is increased by 19.4% from 31kJ/m2 to 37kJ/m2, and the notch impact strength is increased by 54.5%(from 7.7kJ/m2 to 11.9kJ/m2). 2. Thermal properties analysis of PPS/SGF and PPS/LGF composites When the mass fraction of glass fiber is 30%, the thermal deformation temperature of PPS/SGF composite and PPS/LGF composite reaches 250℃ and 275℃, respectively. The thermal deformation temperature of PPS/LGF composite is 10% higher than that of PPS/SGF composite. The main reason is that the introduction of glass fiber makes the network skeleton of reinforced fiber formed inside the composite material, which greatly improves the heat resistance of the composite material. The size of glass fiber in PPS/LGF is longer, and the heat resistance improvement advantage is more obvious....

- New high performance thermoplastic resin

- A crystalline polymer reinforced plastic pps

- Long glass fiber filling plastic

- Customized material PPS self factory made

- Industrial raw material thermoplastic ppa

- High impact resistance lgf

Tags :

-

Xiamen LFT Polypropylene filling long carbon fiber composites PP higher toughness and strengthLong Carbon Fiber Reinforced Polymer (LCFRP) is composed of carbon fiber as the reinforcement material and resin as the matrix material

- Polymeric compounds thermoplastic resin

- White waxy material can be customized compounds

- Thermoplastic synthetic resin injection molding PP instead metal

- polymer PP polypropylene CFRP black carbon filament

- Translucent solid material reinforced plastic

- Industrial use for automotive parts car

Tags :

-

Xiamen LFT-G Nylon 6 Polyamide 6 composite Long Glass Fiber modified plastic 12mm original colorPA6 material PA6 is one of the most widely used materials in the current field, and PA6 is a very good engineering plastic with balanced and good performance. The raw materials for the manufacture of nylon 6 engineering plastic are extensive and inexpensive, and it is not restricted by the technological monopoly of foreign companies. However, in order to make good use of this inexpensive and excellent material, we must first understand it. Today, we will start with glass fiber reinforced PA6 engineering plastics, because it is the most important category of PA6 engineering plastics. Just like any other engineering plastics, PA6 has advantages and disadvantages, such as high water absorption, low temperature impact toughness and dimensional stability is relatively poor. So engineers will use different methods to make PA6 better, which we call modification. At present, the most common method is to blend and modify PA6 with glass fiber (GF). Today, we will take a look at the mechanical properties of PA6 engineering plastics under the glass fiber GF system for reference and help us select materials. PA6-LGF 1. Influence of glass fiber content on PA6 engineering plastics We can find from the application and experiment that the content index is often one of the biggest influencing factors in fiber reinforced composites. As the glass fiber content increases, the number of glass fibers per unit area of the material will increase, which means that the PA6 matrix between the glass fibers will become thinner. This change determines the impact toughness, tensile strength, bending strength and other mechanical properties of glass fiber reinforced PA6 composites. In terms of impact performance, the increase of glass fiber content will greatly increase the notch impact strength of PA6. Taking long glass fiber (LGF) filling PA6 as an example, when the filling volume increases to 35%, the notch impact strength will increase from 24.8J/m to 128.5J/m. But the glass fiber content is not more is better, short glass fiber (SGF) filling volume reached 42%, the impact strength of the material reached the highest 17.4kJ/㎡, but continue to add will let the gap impact strength showed a downward trend. In terms of bending strength, the increase of the amount of glass fiber will make the bending stress can be transferred between the glass fiber through the resin layer; At the same time, when the glass fiber is extracted from the resin or broken, it will absorb a lot of energy, thus improving the bending strength of the material. The above theory is verified by experiments. The data show that the bending elastic modulus increases to 4.99GPa when the LGF (long glass fiber) is filled to 35%. When the content of SGF (short glass fiber) is 42%, the bending elastic modulus reaches 10410MPa, which is about 5 times that of pure PA6. 2. Influence of glass fiber retention length on PA6 composites The fiber length of the glass fiber also has an obvious effect on the mechanical properties of the material. When the length of the glass fiber is less than the critical length (the length of the fiber when the material has the tensile strength of the fiber), the interface binding area of the glass fiber and the resin increases with the increase of the length of the glass fiber. When the composite material is broken, the resistance of the glass fiber from the resin is also greater, so as to improve the ability to withstand the tensile load. When the length of glass fiber exceeds the critical, the longer glass fiber can absorb more impact energy under impact load. In addition, the end of the glass fiber is the initiation point of crack growth, and the number of long glass fiber ends is relatively less, and the impact strength can be significantly improved. The experimental results show that the tensile strength of the material increases from 154.8MPa to 164.4MPa when the glass fiber content is kept at 40% and the length of the glass fiber increases from 4mm to 13mm. The bending strength and notched impact strength increased by 24% and 28%, respectively. Moreover, the research shows that when the original length of the glass fiber is less than 7mm, the material performance increases more obviously. Compared with short glass fiber, long glass fiber reinforced PA6 material has better appearance warping resistance, and can better maintain mechanical properties under high temperature and humidity conditions. TDS for your reference PA6 can be made into long glass fiber reinforced material by adding 20%-60% long glass fiber according to the characteristics of the product. PA6 with long glass fiber added has better strength, heat resistance, impact resistance, dimensional stability and warping resistance than without glass fiber added. Following TDS show the data of PA6-LGF30. Application PA6-LGF has the largest proportion of applications in the automotive industry, by electronic and electrical applications, and also involving machinery and engineering ...

- PA6 thermoplastic resin materials

- nylon 6 granules

- long fiber compounds pa6

- Injection molding plastic

- LFT-G reinforced material

Tags :

-

LFT-G PPS Polyphenylene sulfide LGF composite long glass fiber customized engineering plasticsWhat is the PPS? Polyphenylene sulfide (PPS) is a new thermoplastic resin with high performance. By filling, modified with excellent high temperature resistance, corrosion resistance, wear resistance, flame retardant, balanced physical and mechanical properties and excellent dimensional stability and excellent electrical properties and other characteristics of the new high performance thermoplastic resin, as well as high mechanical strength, chemical resistance, flame resistance, good thermal stability, excellent electrical properties and other advantages. It has the advantages of hard and brittle, high crystallinity, inflammability, good thermal stability, high mechanical strength, excellent electrical properties, strong chemical corrosion resistance and so on. The mechanical properties of pure PPS are not high, especially the impact strength is relatively low. Good creep resistance under load, high hardness; High wear resistance, the wear at 1000 RPM is only 0.04g, and will be further improved after filling F4 and molybdenum disulfide; It also has a certain degree of self-moistening. The mechanical properties of PPS are less sensitive to temperature. What is the PPS-LGF? PPS is one of the best varieties of heat resistance in the engineering plastic department. The thermal deformation temperature of the material modified by glass fiber is generally greater than 260 degrees, and the chemical resistance is second only to PTFE. In addition, it also has small shrinkage, low water absorption, good fire resistance. Good resistance to vibration fatigue, strong resistance to arc, especially at high temperature. Excellent electrical insulation in high humidity. But its disadvantages are brittleness, toughness, low impact strength, after modification, can overcome the above shortcomings, obtain very excellent comprehensive performance. As a plastic, its properties and uses far exceed those of ordinary plastics, and in many ways it is as good as metal materials. Excellent material PPS has the advantages of high temperature corrosion resistance, excellent mechanical properties, can replace metal including stainless steel, copper, aluminum, alloy, etc., is considered to be the best substitute for metal, copper. What is the application of PPS-LGF? PPS is now widely used in automotive, aerospace, household appliances, mechanical construction and chemical industry for a variety of structural parts, transmission parts, insulation parts, corrosion resistant parts and seals. Under the condition of ensuring sufficient strength and other properties, the weight of the product is greatly reduced. Datasheet for reference Details Number Color Length MOQ Package Sample Delivery time Port of Loading PPS-NA-LGF30 Original color (can be customized) 5-25mm above 25kg 25kg/bag Available 7-15 days after shipment Xiamen Poer Production process Trademarks and patents Teams and customers We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.

- PPS Long glass fiber 40

- pps compounds lgf

- pps resin materials lft

- lft-g pps reinforced plastic

- long glass fiber filling pps

- termoplastic resin pps lgf

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文