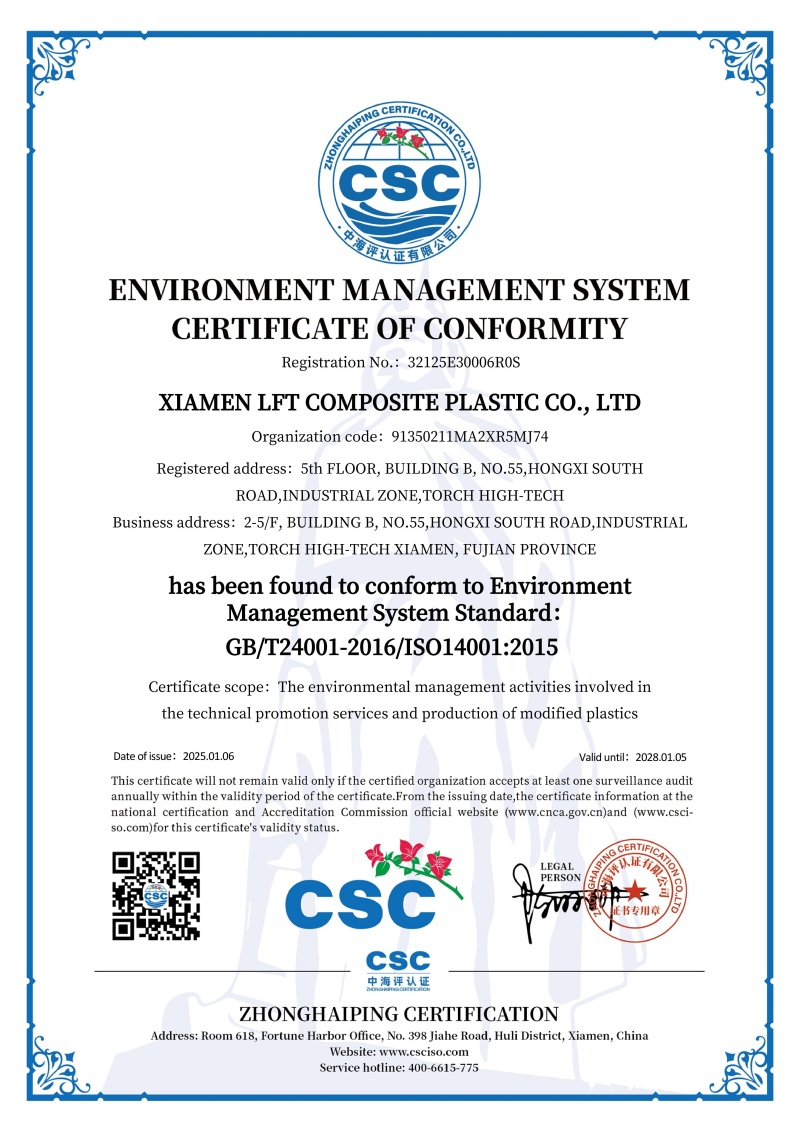

Xiamen LFT Composite Plastic Co., Ltd. Achieves

ISO 14001:2015 Environmental Management Certification.

(See at the bottom)

Xiamen LFT Composite Plastic Co., Ltd. is proud to announce that it has successfully achieved ISO 14001:2015 certification for its environmental management system. This certification underscores the company’s commitment to sustainable practices, environmental responsibility, and continuous improvement in reducing its ecological footprint.

ISO 14001:2015 is a globally recognized standard that outlines the framework for effective environmental management. By adhering to this standard, Xiamen LFT demonstrates its dedication to minimizing environmental impacts across all aspects of its operations, from production to product lifecycle, while complying with relevant environmental regulations.

The certification process involved a thorough assessment of the company’s environmental management practices, policies, and procedures. As part of the certification, Xiamen LFT has committed to ongoing monitoring, measurement, and improvement to ensure that its environmental goals are consistently met. The company is also focused on reducing waste, improving energy efficiency, and optimizing resource use in all areas of its business.

“We are extremely proud to achieve ISO 14001:2015 certification, which further solidifies our dedication to sustainable development,” said Mr. Zhu, Chairman at Xiamen LFT Composite Plastic Co., Ltd. “This achievement reflects our ongoing efforts to improve not only our products and services but also the environmental impact of our operations. We remain focused on our goal of providing innovative, eco-friendly solutions while contributing to a greener future.”

As part of its commitment to environmental stewardship, Xiamen LFT will continue to integrate sustainable practices into its operations, ensuring the long-term success of both the company and the planet.

For more information about Xiamen LFT’s products and services, please visit www.lft-g.com.