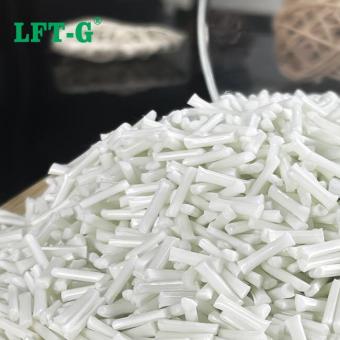

High-content long glass fiber LGF modified nylon PA66 Long Glass fiber Reinforced Polyamide nylon PA66 has extremely high mechanical properties. Excellent long-term heat resistance, dimensional stability, can replace ordinary aluminum alloy materials, and the cost is lower than metal materials.

-

Nylon series Polyamide 66 Long Glass Fiber Reinforced Thermoplastic ResinPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials. About PA66-LGF compounds Nylon 6,6, also written as nylon 6-6, nylon 66, or nylon 6/6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66. It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6. The advantages of nylon 6,6 are that the yield strength is higher than nylon 6 and nylon 610. It has high strength, toughness, rigidity, and low coefficient of friction in a wide temperature range. In addition, it is oil resistant and resistant to chemical reagents and solvents. However, PA66 has strong hygroscopicity and poor dimensional stability, which limits its application. In order to obtain nylon 66 engineering material with higher strength, it should be modified by glass fiber reinforcement. The mechanical properties of long glass fiber reinforced nylon 66 (LGFR-PA66) are obviously better than those of short glass fiber reinforced nylon 66 (SGFR-PA66), and the molding processing performance is also better. It can be molded by various molding methods such as injection molding and compression molding, and complex components can also be formed. Therefore, long glass fiber reinforced nylon 66 can be widely used in building materials, aerospace, electronic devices, furniture and other fields, especially in the automotive industry application market. The production process of long glass fiber reinforced nylon 66 is different from that of short glass fiber reinforced nylon 66. The short glass fiber reinforced nylon 66 particle is chopped under the friction and shearing of screw and barrel, and the short glass fiber reinforced nylon 66 particle is obtained with the length of glass fiber monofilament about 0.5mm. The length of some glass fiber monofilament in the final product is lower than the critical length of reinforcement, and the glass fiber is easy to be extracted from the nylon 66 matrix when the product is stressed. The strength of glass fiber is not fully utilized, and the mechanical properties of the product are not high. Long glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer. Materials Details Number PA66-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.

- PA66 PA 6.6 Enginering materials

- excellent heat resistance with filler

- injection molding products light weight

- car parts toy home applance use

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

LFT-G modified nylon66 PA66 filling long glass fiber compounds electronic appliancesPA66-LGF Long Glass Fiber Reinforced Nylon PA66, or Nylon 66, is a high-performance polyamide widely used in engineering plastics. It offers excellent mechanical properties including tensile strength, flexural strength, and impact resistance, along with superior thermal and chemical stability. With lightweight, high wear resistance, good electrical insulation, and self-extinguishing properties, PA66 is ideal for automotive, electrical, industrial equipment, and construction applications. Why Reinforce PA66 with Long Glass Fiber? While PA66 is versatile, it has limitations: high water absorption, low compressive strength when wet, poor alkali resistance, and potential deformation at ultra-low temperatures. Long glass fiber (LGF) reinforcement addresses these challenges. Adding LGF significantly improves impact resistance, thermal deformation resistance, mechanical performance, molding processability, and chemical resistance. LGF acts as a robust internal skeleton, enhancing the durability and reliability of PA66 components. PA66-LGF Technical Datasheet *The datasheet is tested by Xiamen LFT and provided for reference only.* Applications of PA66-LGF PA66 reinforced with 30% long glass fiber is ideal for high-performance applications such as: Automotive components and structural parts Power tool housings and mechanical parts Industrial equipment components For specialized applications, please consult our technical team. PA66-LGF Product Details Number Color Length Sample MOQ Port of Loading Delivery Time Payment Terms PA66-NA-LGF30 Original color (customizable) 12mm (customizable) Available 25kg Xiamen Port 7-15 days after shipment Discussed Xiamen LFT Composite Plastic Co., Ltd Xiamen LFT Composite Plastic Co., Ltd. is a leading manufacturer specializing in long fiber reinforced thermoplastics (LFT & LFRT), including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our thermoplastic LFT can be applied in LFT-G injection molding, extrusion molding, and LFT-D molding. We provide products according to customer requirements with fiber lengths from 5 to 25mm. Our continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 certifications and hold numerous national patents and trademarks. Our Services Technical parameters and leading-edge design of LFT & LFRT materials Mold front design recommendations Technical support for injection molding and extrusion molding processes

- Low warpage electronic appliance

- self owing pa66 pellets

- high strength and high toughness reinforced pa66 pellets

- best long glass fiber pa66 lgf30 granules

- PA66 6 twin screw lgf pellets

- Long Fiber PA66 granules Application

Tags :

-

PA66 Pellets Glass FiberNylon 6,6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66. It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6.

- nylon 66 pa66

- fiber reinforced nylon

- reinforced glass fiber

- nylon compounds

- glass fibre reinforced nylon

- glass fiber reinforced plastic

Tags :

-

New Materials LGF Polyamide 66 Nylon for Structural ApplicationsOur PA66 Long Glass Fiber Reinforced Material is a high-performance thermoplastic composite developed for applications demanding superior mechanical strength, dimensional stability, and heat resistance. Ideal for metal replacement and high-load structural components.

- nylon pa66 gf30

- china supplier pa 66

- long fiber composites

- gfrp price per kg

- engineer nylon

- injection molding nylon

Tags :

-

Long Glass Fiber Reinforced Composites PA 66 Series CopolymerLong glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer.

- pa66 glass fiber

- pa66 compound

- pa66 plastic material

- pa66 pellets

- custmized dyed nylon pa66 supply

Tags :

-

High Toughness Nylon PA66 Long Glass Fiber Polymer PelletsLong glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer.

- flammability properties

- lightweight composite

- glass fiber reinforced polymer price per kg

- nylon composites

- polyamide 66

- nylon glass

Tags :

-

LFT Modified Polyamide 66 filled long glass fiber compoundsLong glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer.view more

-

Nylon 6,6 Composite Pellets with 20-60% Long Glass Fiber ContentPA66 long glass fiber reinforced material offers excellent mechanical strength, high thermal stability, and outstanding dimensional stability, making it ideal for demanding structural applications. It is widely used in automotive, electrical, and industrial components where durability and precision are critical.

- glass fiber

- pa66 material

- glass fibre reinforced polyamide

- polyamide polymers

- density polyamide

- nylon fiber properties

Tags :

-

LFT Nylon Series Polyamide 6,6 Long Glass Fiber Reinforced CompositesThe mechanical properties of long glass fiber reinforced nylon 66 (LGFR-PA66) are obviously better than those of short glass fiber reinforced nylon 66 (SGFR-PA66), and the molding processing performance is also better. It can be molded by various molding methods such as injection molding and extrusion molding, and complex components can also be formed.view more

-

Nylon Polyamide 66 Long Fiber Reinforced CompoundsThe mechanical properties of long glass fiber reinforced nylon 66 (LGFR-PA66) are obviously better than those of short glass fiber reinforced nylon 66 (SGFR-PA66), and the molding processing performance is also better. It can be molded by various molding methods such as injection molding and compression molding, and complex components can also be formed.

- PA66 GFRP 40 30

- pa66-gf30 polymaker application

- Thermoplastic resin

- pA66 fiberglass

- EDM wholesell PA 66 materials

- Best price PA66

Tags :

-

New Materials LGF Polyamide 66 Nylon for Structural ApplicationsOur PA66 Long Glass Fiber Reinforced Material is a high-performance thermoplastic composite developed for applications demanding superior mechanical strength, dimensional stability, and heat resistance. Ideal for metal replacement and high-load structural components.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文