new blog

High-performance thermoplastic composites can replace metals. Although PEEK is regarded as the benchmark for engineering performance, reinforced PPS offers a truly cost-effective alternative.

The demand for engineering thermoplastics such as PC and high-performance thermoplastics like PEEK is steadily increasing in industrial applications. These materials, when produced in the form of 3D printing filaments, offer lightweight alternatives to metals for industries such as aerospace and energy.

By incorporating reinforcements, the properties of these high-performance plastics can be further enhanced. For example, the addition of chopped carbon fibers improves both strength and stiffness. Such reinforcements can be applied not only to low- and mid-range engineering plastics but also to high-performance thermoplastics. As long as the 3D printer nozzle can handle abrasive materials, these composites can be printed as easily as standard thermoplastics.

However, a major drawback of high-performance composites such as reinforced PEEK is the high cost of the required 3D printing hardware. These materials demand extremely high extrusion and chamber temperatures, and the equipment capable of meeting these requirements often costs six figures—undermining one of the key advantages of plastic 3D printing: cost efficiency.

This article explores carbon fiber reinforced PPS as an alternative that delivers performance comparable to metals and PEEK, while offering significant advantages in temperature requirements and overall cost.

Polyphenylene sulfide (PPS) is a semi-crystalline thermoplastic commonly classified as a high-performance polymer, alongside materials such as PEEK and PEI. It is widely used in machining, mold manufacturing, and additive manufacturing due to its excellent mechanical strength, superior heat resistance compared to standard and engineering thermoplastics, and inherent flame retardancy.

One of the most remarkable properties of PPS is its outstanding chemical resistance. It can withstand a wide range of acids, bases, and solvents, and even shows partial resistance to strong oxidizing agents under certain conditions. However, for particularly aggressive oxidizers such as chlorine dioxide, additional coatings or linings may be required for protection.

With its exceptional performance and more affordable cost compared to PEEK, PPS has found broad applications across various industries. Its mechanical and chemical durability make it ideal for automotive, energy, and chemical processing sectors, while its flame-retardant and self-extinguishing characteristics make it a preferred material for electrical and electronic components, such as surface-mount devices (SMT), motor housings, and transistor encapsulations.

Beyond being an outstanding thermoplastic, PPS is also a reliable replacement for metals such as steel and aluminum. Its thermal stability and chemical resistance enable it to perform effectively in harsh chemical environments, offering strong protection against corrosion and automotive fluids.

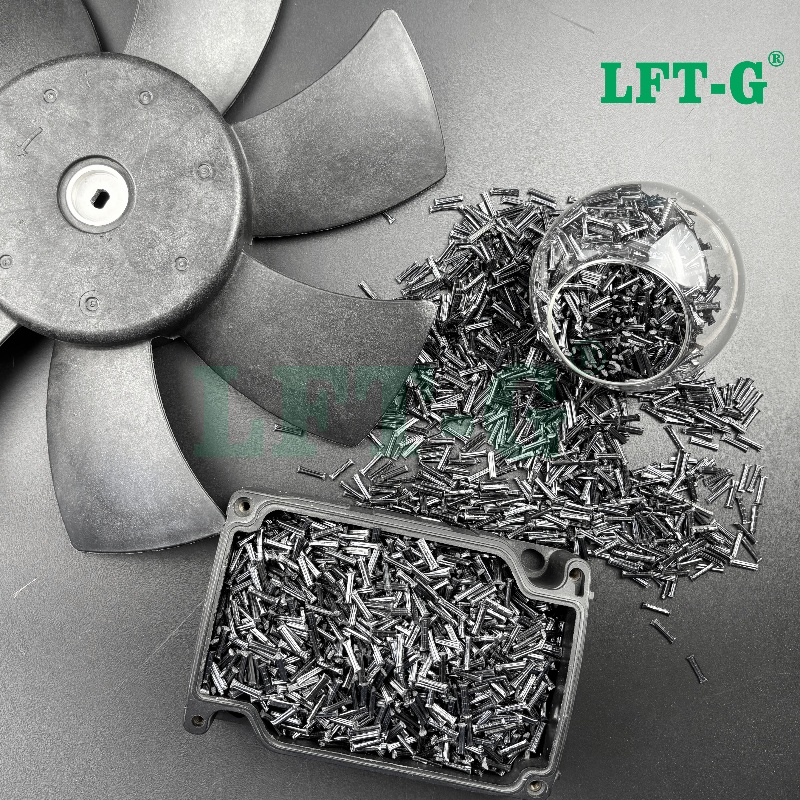

To improve its strength and rigidity, PPS is often reinforced with chopped carbon fibers or glass fibers, resulting in composite materials with enhanced performance. In fact, PPS is more commonly available in a filled form rather than unfilled.

Researchers have noted that “the addition of carbon fibers significantly enhances the mechanical properties, tribological behavior, post-fire structural integrity, as well as the electrical and thermal conductivity of PPS blends and composites.”

Discover how Long Carbon Fiber Reinforced PPS can elevate your product performance while reducing weight and cost. Our experienced technical team provides full customization and material support for your project.

Contact Our Team →