-

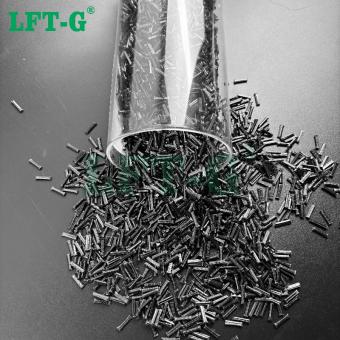

PPS High Temperature Resistance with Glass FiberPPS long carbon fiber reinforced materials combine excellent mechanical strength, high thermal stability, and outstanding chemical resistance. They are ideal for precision parts used in high-temperature, corrosive, or high-stress environments.

- pps resin suppliers

- long fiber compounds

- carbon fiber reinforced thermoplastic

- lft g for automobile market

- applications of polymers in aerospace engineering

- carbon thermoplastic

Tags :

-

LFT Long Fiber PEEK High Mechanical Properties Plastic for DroneLFT long carbon fiber reinforced PEEK material offers unmatched strength, stiffness, and exceptional resistance to high temperatures and chemicals. Its superior durability and dimensional stability make it ideal for demanding aerospace, automotive, and industrial applications, where performance and reliability are crucial.view more

-

Long Carbon Fiber Polypropylene Modified CompoundsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- pp 30 cf

- carbon fiber resistance

- difference between copolymer and homopolymer

- long-fiber thermoplastic composite solutions

- automotive thermoplastic composites

Tags :

-

Long Carbon Fiber Copolymer Polypropylene Modified CompoundsCarbon fiber reinforced composite (CFRP) is composed of carbon fiber as a reinforcement material and resin as a matrix material, and early carbon fiber composite materials are mainly used in the military field. With the improvement of material properties, molding process and price cost, carbon fiber composite materials are more and more used in general industry and sports and leisure fields.view more

-

PPS Thermoplastic Plastics Long Carbon Fiber Plastic CompoundsDue to its excellent mechanical properties, thermoplastic carbon fiber is widely used in the automotive field of fuel system components, sensors, shell components. It is because of the high strength and stiffness of PPS-LCF, and the finished parts are not easy to damage. PPS-LCF also has a relatively low coefficient of thermal expansion to ensure the stability of the finished product.

- carbon fiber frameset

- carbon fiber handlebars

- printing carbon fiber

- pps injection

- pps composite

Tags :

-

Long Carbon Fiber Polypropylene Modified CompoundsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- lft materials

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文