-

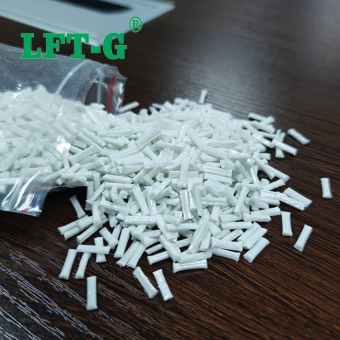

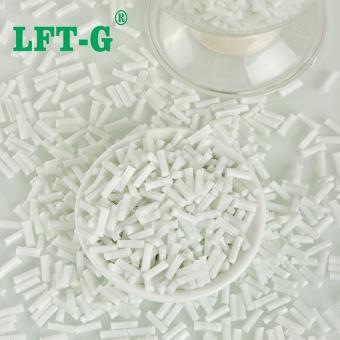

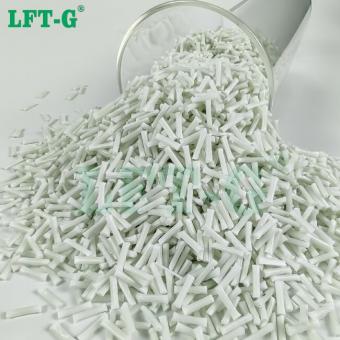

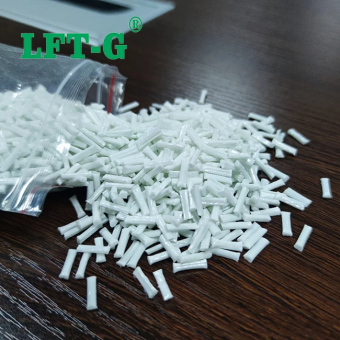

LFT-G Polyamide6 nylon6 filling long glass fiber orginal color for automotive partsWhat is PA6 plastic? polyamide (PA), usually called Nylon, is a hetero-chain polymer containing amide group (-NHCo -) in the main chain. It can be divided into aliphatic group and aromatic group. It is the earliest developed and the most used thermoplastic engineering material. Polyamide main chain contains many repeated amide group, used as a plastic called nylon, used as a synthetic fiber called nylon. A variety of different polyamides can be prepared according to the number of carbon atoms contained in binary amines and dibasic acids or amino acids. At present, there are dozens of polyamides, among which polyamide-6, polyamide-66 and polyamide-610 are the most widely used. Polyamide-6 is an aliphatic polyamide, with light weight, strong strength, wear resistance, weak acid and alkali resistance and some organic solvents, easy molding and processing and other excellent properties, widely used in fiber, engineering plastics and thin films and other fields, but PA6 molecular chain segment contains strong polarity amide groups, easy to form hydrogen bonds with water molecules, The product has the disadvantages of large water absorption, poor dimensional stability, low impact strength in dry state and low temperature, strong acid and alkali resistance. Advantages of nylon 6: High mechanical strength, good toughness, high tensile and compressive strength. Outstanding fatigue resistance, the parts after repeated bending can still maintain the original mechanical strength. High softening point, heat resistant. Smooth surface, small friction coefficient, wear-resistant. Corrosion resistance, very resistant to alkali and most salts, also resistant to weak acids, oil, gasoline, aromatic compounds and general solvents, aromatic compounds are inert, but not resistant to strong acids and oxidants. It can resist the corrosion of gasoline, oil, fat, alcohol, alkaline and so on, and has good anti-aging ability. It is self-extinguishing, non-toxic, odorless, good weather resistance, inert to biological erosion, and has good antibacterial and mildew resistance. Has excellent electrical performance, good electrical insulation, nylon volume resistance is high, high breakdown voltage resistance, in dry environment, can work frequency insulation material, even in high humidity environment still has good electrical insulation. Light weight, easy dyeing, easy forming, because of low melting viscosity, can flow quickly. Disadvantages of Nylon 6: Easy to absorb water, water absorption, saturated water can reach more than 3%. Poor light resistance, in the long-term high temperature environment will oxidize with oxygen in the air, the color turns brown at the beginning, and the subsequent surface is broken and cracked. Injection molding technology requirements more strict, the existence of trace moisture will cause great damage to the quality of molding; The dimensional stability of the product is difficult to control because of thermal expansion. The existence of sharp Angle in the product will lead to stress concentration and reduce the mechanical strength; If the wall thickness is not uniform, it will lead to the distortion and deformation of the parts. High precision of equipment is required in post-processing. Will absorb water, alcohol and swelling, not resistant to strong acid and oxidant, can not be used as acid-resistant materials. Why filling Long Glass Fiber? PA6 has excellent properties such as light weight, strong strength, abrasion resistance, weak acid and alkali resistance and some organic solvents, and easy molding and processing. It is widely used in the fields of fibers, engineering plastics and films. However, the molecular chain segment of PA6 contains highly polar amide groups, which are easy to form hydrogen bonds with water molecules. The product has the disadvantages of large water absorption, poor dimensional stability, low impact strength in dry state and low temperature, strong acid and alkali resistance. With the development of science and technology and the improvement of life quality, the defects in some properties of traditional PA6 materials have limited its development in some fields. In order to improve the performance of PA6 and expand its application field, PA6 should be modified. Filling enhancement modification is a common method for physical modification of PA6. It refers to the modification of PA6 by adding fillers such as glass fiber and carbon fiber into the matrix to significantly improve the mechanical properties, flame retardant properties, thermal conductivity and dimensional stability of the material. What is application of PA6-LGF? Modified section of 30% long glass fiber reinforced PA6 is the ideal material for processing power tool shell, power tool parts, engineering machinery parts and automobile parts. Its mechanical properties, dimensional stability, heat resistance and aging resistance have been significantly improved. The fatigue resistance strength is 2.5 times that of unenha...

- Polyamide 6 composite properties

- lgf thermoplastic resin good price

- High impact PA6 instead metal plastic

- injection molding plastic gf30 filter

- pa6 filling long glass fiber customized

- Reinforced plastic lightweight compounds

Tags :

-

LFT-G fiber filled PBT composites high strength injection moldingOur long glass fiber reinforced PBT compounds offer high strength and excellent chemical compatibility, making them ideal for industrial applications where durability and performance are critical.

- chemical compatibility PBT

- long glass fiber filler polymer

- natural color pbt supplier

- PBT application reinforced materials

- compounds resin high strength

- Long fiber PBT for industrial use

Tags :

-

Xiamen LFT-G HDPE filling long glass fiber thermoplasitc reinforced compoundsHDPE-LGF High density polyethylene (HDPE)/ glass fiber (LGF) composites were prepared by twin-screw extrusion mechanism, and the mechanical properties and non-isothermal crystallization behavior of HDPE/LGF composites were studied. The results show that the impact strength of the composite can be improved by MAH-g-POE, and the interface bond between the glass fiber and HDPE is good. The Avrami index (n) of the composite does not change with the cooling rate. Datasheet Application Packages Xiamen LFT composite plastic Co.,Ltd Come and find us! We will offer you: 1. LFT & LFRT material technical parameters and leading edge design. 2. Mold front design and recommendations. 3. Provide technical support such as injection molding and extrusion molding.

- HDPE filling lgf20

- lgf hdpe composite materials

- reinforced hdpe plastic resin

- long glass fiber reinforced hdpe

- Thermoplastic hdpe lgf compounds

- hdpe resin with filler

Tags :

-

China LFT-G Nylon Polyamide 6 composite Long Glass Fiber modified plastic original colorPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials.

- PA6 thermoplastic resin materials

- nylon 6 granules

- glass fiber reinforced plastics granules

- long fiber compounds pa6

- Injection molding plastic

- LFT-G reinforced material

Tags :

-

LFT Long Glass Fiber Reinforced High Density Polyethylene for Industrial UseHigh-density polyethylene (HDPE), also called polyethylene high-density (PEHD), is a thermoplastic polymer made from the monomer ethylene. When used for HDPE pipes, it is sometimes called "alkathene" or "polythene." With a high strength-to-density ratio, High-density polyethylene (HDPE) is used to produce corrosion-resistant piping. In addition, HDPE is commonly recycled.

- hdpe glass

- fiber reinforced hdpe composite pipe

- lft pellets

- long glass fiber

- long fiber compounds

- long fiber thermoplastic composites

Tags :

-

China LFT High Toughness MXD6 Composite filling Long Glass Fiber Original ColorNylon - MXD6 is a kind of crystalline polyamide resin, which is synthesized by the condensation of m-benzoylamine and adipic acid.

- Crystalline nylon resin mxd6 gf good price

- Composite materials with long glass fiber mxd6

- Higher performance plastic mxd6

- Made in China products compounds mxd6

- Customized plastic fiber glass add high sstrength mxd6

- Thermoplastic resin thermoplastic resin

Tags :

-

High Strength ABS Resin Long Glass Fiber filled PelletsABS long glass fiber reinforced modified materials are engineering plastics with high strength, excellent impact toughness, and heat resistance, widely used in industries such as automotive, electronics, and home appliances. The reinforcement of long glass fibers enhances the material's rigidity and fatigue resistance. It is suitable for industrial products requiring high strength and performance.

- glass fiber reinforced abs

- abs glass fiber compound

- abs granules manufacturer

- natural abs color

- LFT advanced materials

- Acrylonitrile Butadiene Styrene

Tags :

-

Advanced Carbon Materials PP Resin Long Carbon Fiber filled PelletsPP long carbon fiber reinforced material offers exceptional strength and lightweight properties, making it ideal for high-performance applications. Its superior rigidity and impact resistance enhance product durability and structural integrity. Widely used in automotive, drones, and industrial components, it ensures excellent mechanical performance.

- PP CF30

- Polypropylene granules manufacturer

- PP copolymer pellets

- copolymer vs homopolymer pp

- pp carbon fiber compound

- Carbon Fiber Reinforced Materials

Tags :

-

Advanced Carbon Materials Nylon 12 Resin Long Carbon Fiber Reinforced PelletsPA12 long carbon fiber reinforced material offers excellent impact resistance, low moisture absorption, and dimensional stability, making it ideal for demanding engineering applications. With superior mechanical properties and lightweight advantages, this material is widely used in automotive, electronics, and electrical industries. Its high strength and rigidity ensure stable performance even in harsh environments.

- China manufacturer carbon fiber compounds

- pa12 pellets

- PA12 black

- pa12 carbon fiber

- PA12 polymer

- carbon fiber nylon pa12

Tags :

-

Advanced Carbon Materials Polypropylene Resin Long Carbon Fiber Reinforced PelletsPolypropylene long carbon fiber reinforced material provides exceptional strength, stiffness, and lightweight properties, making it an ideal choice for high-performance engineering applications. With excellent impact resistance, chemical resistance, and cost-effectiveness, this material is widely used in automotive, industrial, and consumer goods sectors. Its durability and thermal stability ensure reliable performance even under challenging conditions.

- Polypropylene raw materials

- PA12 black carbon

- PP carbon fiber

- PP polymer

- carbon fiber nylon pp

Tags :

-

Advanced Carbon Materials Polyphenylene Sulfide Resin Long Carbon Fiber Reinforced PelletsPPS long carbon fiber reinforced material features outstanding thermal stability, exceptional chemical resistance, and excellent mechanical strength, making it ideal for high-performance engineering applications. With superior stiffness, low moisture absorption, and inherent flame retardancy, this material is widely used in automotive, aerospace, and electrical industries. Its high strength and dimensional stability ensure reliable performance even in extreme environments.view more

-

LFT-G fiber filled PBT composites high strength injection moldingOur long glass fiber reinforced PBT compounds offer high strength and excellent chemical compatibility, making them ideal for industrial applications where durability and performance are critical.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文