-

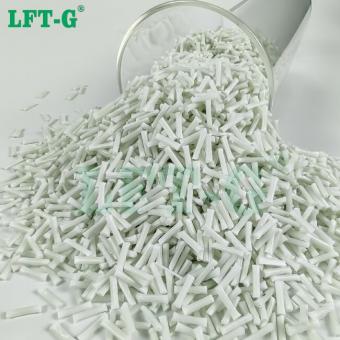

LFT-G modified ABS compounds Long Glass Fiber for automotive partsABS also has good dimensional stability and can be easily machined or drilled after molding.

- Modified material lft injection molding

- ABS compounds long glass fiber

- lgf injection mold abs for engineering

- reinforced material abs filling lgf

- ABS-LGF30 thermoplastic resin

- Thermoplastic resin ABS

Tags :

-

Xiamen LFT-G HDPE filling long glass fiber thermoplasitc reinforced compoundsHigh-density polyethylene (HDPE), also called polyethylene high-density (PEHD), is a thermoplastic polymer made from the monomer ethylene. When used for HDPE pipes, it is sometimes called "alkathene" or "polythene." With a high strength-to-density ratio, High-density polyethylene (HDPE) is used to produce corrosion-resistant piping. In addition, HDPE is commonly recycled.

- HDPE filling lgf20

- lgf hdpe composite materials

- reinforced hdpe plastic resin

- long glass fiber hdpe

- Thermoplastic hdpe lgf

- hdpe resin compounds

Tags :

-

dLong Fiber Composite Materials | LFT body { font-family: 'Inter', sans-serif; margin: 0; line-height: 1.6; color: #333; background-color: #f7f7f7; } header { background-color: #009245; color: white; padding: 2rem; text-align: center; } header h1 { font-size: 2.5rem; margin-bottom: 0.5rem; } header p { font-size: 1.2rem; color: #c0c0c0; } nav { display: flex; justify-content: center; background-color: #007a38; } nav a { color: white; text-decoration: none; margin: 0 1rem; padding: 1rem 0; transition: color 0.3s; } nav a:hover { color: #fca311; } section { max-width: 1200px; margin: 3rem auto; padding: 0 2rem; background-color: white; border-radius: 12px; box-shadow: 0 4px 12px rgba(0,0,0,0.1); } h2 { text-align: center; font-size: 2rem; margin-bottom: 1rem; color: #009245; } p { font-size: 1rem; color: #555; } .grid { display: grid; grid-template-columns: repeat(auto-fit, minmax(280px, 1fr)); gap: 2rem; margin-top: 2rem; } .card { padding: 1.5rem; background-color: #f7f7f7; border-radius: 8px; transition: transform 0.3s, box-shadow 0.3s; cursor: pointer; } .card:hover { transform: translateY(-5px); box-shadow: 0 8px 20px rgba(0,0,0,0.15); } .accordion { background-color: #007a38; color: white; cursor: pointer; padding: 1rem; width: 100%; border: none; text-align: left; outline: none; font-size: 1.1rem; margin-bottom: 0.5rem; border-radius: 6px; transition: background-color 0.3s; } .accordion:hover { background-color: #009245; } .panel { padding: 0 1rem; display: none; background-color: #f1f1f1; overflow: hidden; border-radius: 0 0 6px 6px; } .video-container { position: relative; padding-bottom: 56.25%; height: 0; overflow: hidden; margin-top: 2rem; } .video-container iframe { position: absolute; top:0; left:0; width:100%; height:100%; border-radius: 12px; } footer { background-color: #009245; color: white; text-align: center; padding: 2rem; margin-top: 3rem; } footer a { color: #fca311; text-decoration: none; } /* Button styling */ .btn { display: inline-block; background-color: #fca311; color: white; padding: 0.8rem 1.5rem; border-radius: 6px; text-decoration: none; margin-top: 1rem; transition: background-color 0.3s; } .btn:hover { background-color: #e59400; } form { display: flex; flex-direction: column; gap: 1rem; margin-top: 1rem; } input, textarea { padding: 0.8rem; border-radius: 6px; border: 1px solid #ccc; font-size: 1rem; } input[type="submit"] { background-color: #009245; color: white; border: none; cursor: pointer; transition: background-color 0.3s; } input[type="submit"]:hover { background-color: #007a38; } Long Fiber Composite Materials High-performance reinforced thermoplastics for industrial applications worldwide Overview Advantages Applications Specifications Video Contact Product Overview Our long fiber reinforced thermoplastic (LFT) materials are engineered for superior strength, impact resistance, and dimensional stability. They provide an ideal solution for replacing metal components, reducing weight while maintaining high performance. Material Types Available in PA6, PA66, PPA, PBT, and TPU variants, all reinforced with long glass or carbon fibers. Mechanical Strength High tensile, flexural, and impact strength compared to traditional short fiber materials. Thermal Resistance Excellent heat resistance for automotive, electrical, and industrial applications. Key Advantages High Strength & Stiffness Long fibers form a continuous network inside the matrix, efficiently transferring stress and enhancing mechanical performance. Weight Reduction Replace metals with LFT materials to achieve significant weight reduction without compromising strength. Impact & Fatigue Resistance Superior impact resistance compared to short fiber reinforced plastics, ideal for safety-critical components. Applications Automotive Powertrain components, structural parts, interior & exterior trims. Electronics Housings, connectors, and thermal management solutions. Industrial Power tools, machinery parts, and consumer appliances. Technical Specifications Property Unit Typical Value Tensile Strength MPa 200-300 Flexural Modulus GPa 15-25 Impact Strength kJ/m² 50-80 Heat Deflection Temp °C 250-300 Product Video Contact Us You can reach us instantly via WhatsApp or send us an email for inquiries or sample requests. WhatsApp Chat Email Us © 2025 LFT Composite Materials. All rights reserved. WhatsApp | Email: sale02@lfrtplastic.com

- d

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文