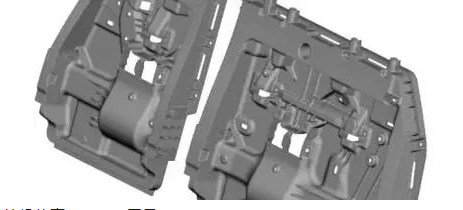

The resin parts of traditional car seats contain metal reinforcement, which increases the cost of the process. The hope is to obtain a whole injection parts without complex, expensive processing. To meet the requirements, an exclusive 35% fiberglass reinforced, impact-resistant modified polyamide PA6 product was used along with its proprietary computer simulation (CAE) tool that can be used in multiple stages of development.

Basf's proprietary computer simulation (CAE) tools

"I classify the third row seat design of the 2021 Toyota Senna as an enabling technology," said the developer. It is the first all-injection molded seat back of its kind to be designed without any inserts, and one of the design challenges was to ensure the seat had high elongation and impact resistance to meet crash-avoidance requirements. "At the same time, we focused on the strength and stiffness of the seats, because the third row also supports the floor."

Contact us, we will offer you the best materials with the best price.