-

China Carbon Fiber Polyphenylene Sulfide Modified CompoundsPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- plastic granules price per kg

- long fibre reinforced thermoplastics

- PPS Plastic

- pps melting point

- Injection molding pps

- Engineering plastic

Tags :

-

ProFiber Long Glass Fiber Reinforced PP High Performance Homopolymer for Injection MoldingOur Glass Fiber Reinforced Polymer with High-Performance offers exceptional strength and durability, perfect for injection molding PP applications.

- Glass Fiber Reinforced Polymer

- High-Performance PP Material

- Injection Molding PP

- Copolymer Plastic Material

- Reinforced Thermoplastic

- Durable Plastic for Automotive

Tags :

-

China Carbon Fiber Polyphenylene Sulfide Modified CompoundsPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.view more

-

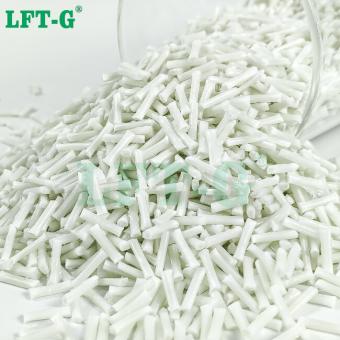

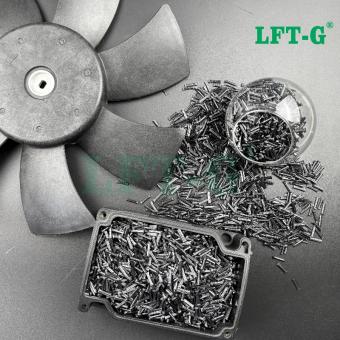

Xiamen LFT PP Polypropylene engineeing plastic long glass fiber composite granules 12mmWhat is Long Glass Fiber (LGF)? Long glass fiber reinforced plastics (LFT) are engineered materials in which long glass fibers and additives are incorporated into a base thermoplastic. This significantly improves mechanical strength, heat resistance, dimensional stability, and the overall performance of the material. Why Reinforce with Long Glass Fiber? High heat resistance: LFT significantly increases the thermal performance, especially for nylon-based plastics. Reduced shrinkage & higher rigidity: Fiber reinforcement restricts polymer chain movement, improving dimensional stability and stiffness. Improved impact resistance: Reinforced plastics are less prone to stress cracking and have better toughness. High strength: Long glass fibers increase tensile, compressive, and bending strength. Flame retardancy: Most LFT materials are self-extinguishing due to additives and fiber content. Why Choose Long Glass Fiber over Short Glass Fiber? Longer fiber length significantly enhances mechanical properties. High specific stiffness and strength with excellent impact resistance, ideal for automotive applications. Superior creep resistance and dimensional stability for precision parts. Excellent fatigue resistance for long-life components. Improved stability under hot and humid environments. Minimal fiber damage during molding due to relative fiber movement in the mold. Appearance of PP-LGF Applications of PP-LGF Automotive Parts Front end modules, door modules, shift mechanisms, electronic accelerator pedals, dashboards, cooling fans, battery carriers, bumper brackets, underbody protection plates, sunroof frames, etc. – replacing reinforced PA or metal components. Household Appliances Washing machine drums, brackets, air conditioning fans, etc. – replacing short glass fiber reinforced PA and metal components. Communications, Electronics, Electrical Appliances High-precision connectors, igniter components, coil shafts, relay bases, microwave transformer frames, solenoid valve housings, scanner components, etc. Other Applications Power tool housings, water pump/meter housings, impellers, bicycle frames, skis, locomotive pedals, safety helmets, safety shoes – replacing short fiber reinforced PA or PPO. Datasheet for Reference About Us Xiamen LFT Composite Plastics Co., Ltd. is a leading supplier of Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) reinforced thermoplastics. Our LFT materials support injection molding, extrusion molding, and are available in fiber lengths of 5–25mm, tailored to customer requirements. ISO9001 & IATF16949 certified, our products are patented and widely used in automotive, electronics, industrial, and defense applications. What We Offer Technical data and guidance for LFT & LFRT materials. Mold design recommendations for optimized production. Injection molding and extrusion support for consistent product quality.

- Polypropylene filling lgf GFRP 30

- thermopalstic Polymer virgin grade

- LFT-G car parts home appliance parts

- PP resin GF made in China modified plastic

- long fiber compounds pp instead metal and steel

- injection molding pp composite

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文