-

High-Performance Long Glass Fiber Reinforced ABS Material for Industrial ApplicationsLong glass fiber reinforced ABS material combines high strength and impact resistance, making it ideal for automotive parts, industrial applications, and electronic components, with excellent performance in injection molding processes.

- Long Glass Fiber Reinforced ABS Material Applications

- High Strength ABS Plastic with Glass Fiber

- Lightweight ABS Composite for Automotive Parts

- Injection Molding ABS with Glass Fiber Reinforcement

- Impact-Resistant ABS Material for Industrial Use

- Glass Fiber Reinforced ABS for Electronics Components

Tags :

-

ProFiber Long Glass Fiber Reinforced PP – High-Performance Homopolymer for Injection MoldingOur Glass Fiber Reinforced Polymer with High-Performance offers exceptional strength and durability, perfect for injection molding PP applications.

- Glass Fiber Reinforced Polymer

- High-Performance PP Material

- Injection Molding PP

- Copolymer Plastic Material

- Reinforced Thermoplastic

- Durable Plastic for Automotive

Tags :

-

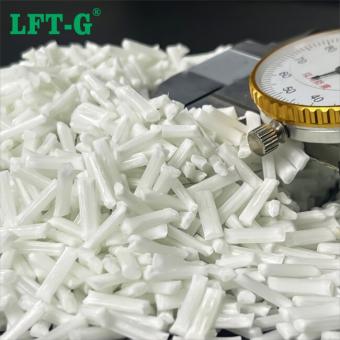

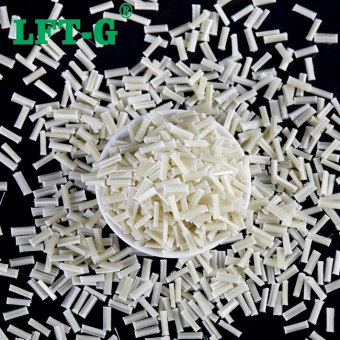

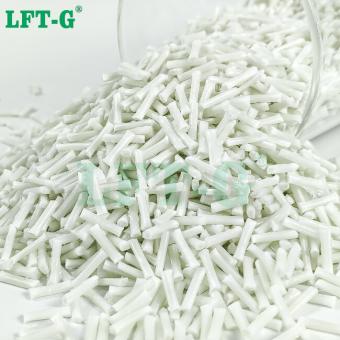

LFT PP Polypropylene engineeing plastic long fiber composite granules 12mmPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer.

- composite wind turbine blades

- flow marks in injection molding

- pp 30 gf

- polymer and copolymer

- compoosite

- modified plastic

Tags :

-

Xiamen LFT Polyamide 6,6 Long Glass Fiber Reinforced Thermoplastic Resin Nylon pelletsHigh melting points, Abrasion resistance, Poor chemical resistance, and High water absorption

- Polyamide 66 PA66 glass fiber reinforcement

- lft gf30 instead metal and steel lightweight

- easy to process good price

- high flexibility and durability composites plastic

- car frame injection molding

- hot sell compounds

Tags :

-

Xiamen LFT Thermoplastic Polyurethane (TPU) Long Glass Fiber Reinforced Thermoplastic CompoundsThermoplastic Polyurethane is soft and elastic, with excellent tensile and tear strength. For this reason, it is often used to make parts that demand a rubber-like elasticity. TPU is a little bit expensive than other resins, but there is no substitute for many applications, such as protective wire and cable sheaths. Another advantage is that TPU improves the grip for products that need to be held securely in hand. About TPU-LGF compounds What Products Are Best Manufactured via Thermoplastic Polyurethane (TPU)? Some of the TPU products manufactured are automotive instrument panels, caster wheels, sporting goods, power tools, drive belts, medical devices, footwear and etc. What is Thermoplastic Polyurethane (TPU) for Plastic Injection Molding? ETPU is a tough, highly abrasion-resistant resin that bridges the gap between rubbers and plastics. TPUs can be formulated to be rigid or elastomeric. TPU exhibits a high flex before break and is ideal for wheels and door panels. What is the Molding Temperature for Thermoplastic Polyurethane (TPU)? depending on the TPU being molded. Materials Details Number TPU-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.

- High performance thermoplastic engineering plastics

- excellent heat resistance with filler

- injection molding products light weight

- excellent tensile and tear strength

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

LFT Nylon 12 Polyamide plastic Long Glass Fiber Filled Composites pelletsPA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties.

- High impact strength Injection molding

- modified thermoplastic resin LFRT

- structural parts car gears and bearings

- versatile engineering plastic

- polymers manufactuer of China factory price

- good price plastic resin PA 12

Tags :

-

Homopolymer Polypropylene With Filler Long Glass Fiber Reinforced for InjectionHomopolymer long glass fiber reinforced polypropylene (PP) offers excellent mechanical properties, including high strength, impact resistance, and dimensional stability. With a glass fiber content ranging from 20% to 60%, it is ideal for applications in automotive, industrial machinery, and power tools, providing a lightweight yet durable alternative to traditional metals.

- homo PP home appliance use

- Polypropylene resin manufacture factory

- Thermoplastic resin made in China

- pp glass fiber roving injection molding use

- Customized PP Materials

- Best priice PP high toughness lightweight

Tags :

-

TPU Thermoplastic Urethane Long Glass Fiber Reinforced CompoundsETPU is a tough, highly abrasion-resistant resin that bridges the gap between rubbers and plastics. TPUs can be formulated to be rigid or elastomeric. TPU exhibits a high flex before break and is ideal for wheels and door panels.

- TPU for Lightweight Automotive Parts

- Industrial TPU Composite Materials

- TPU for Injection Molding

- High-Performance TPU Composites

- Long Fiber Reinforced TPU

- china manufacturer TPU good price warehouse

Tags :

-

ABS Acrylonitrile Butadiene Styrene Long Glass Fiber Reinforced CompoundsABS is another preferred type of engineering plastic that is valued for its chemical and thermal stability, strength, toughness, and glossy finish. Its host of desirable properties make it a versatile material. It is used in everything from consumer products like toys and bicycle helmets to automotive applications such as interior trim pieces, housings for electronics, and more.

- ABS for Lightweight Automotive Parts

- Industrial ABS Composite Materials

- ABS for Injection Molding

- High-Performance ABS Composites

- Long Fiber Reinforced ABS

- china manufacturer ABS good price warehouse

Tags :

-

PPS Polyphenylene Sulfide Long Glass Fiber Reinforced CompoundsPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- PPS for Lightweight Automotive Parts

- Industrial PPS Composite Materials

- PPS for Injection Molding

- High-Performance PPS Composites

- Long Fiber Reinforced PPS

- china manufacturer PPS good price warehouse

Tags :

-

Xiamen LFT PPA Polyphthalamide filled Long Glass Fiber reinforced plastic resinPPA (Polyphthalamide) is polyphthalamide.PPA is a kind of thermoplastic functional nylon with both semi-crystalline structure and non-crystalline structure. It is prepared by polycondensation of phthalic acid and phthalenediamine. It has excellent thermal, electrical, physical and chemical resistance and other comprehensive properties.

- PPA long fiber compounds manufacturer

- ppa granules natural polymer producer

- PPA producer LGF glass fiber

- China wholesale PPA resin pellet filler

- Thermoplastic materials PPA maker

- Injection molding PPA GF

Tags :

-

Factory Supply PPA Polyphthalamide Long Glass Fiber Reinforced CompoundsPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- PPA for injection molding products

- PPS to replace metal

- PPA with high properties for demanding industry

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文