item no.:

PA6-NA-LCF40Payment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaLead Time:

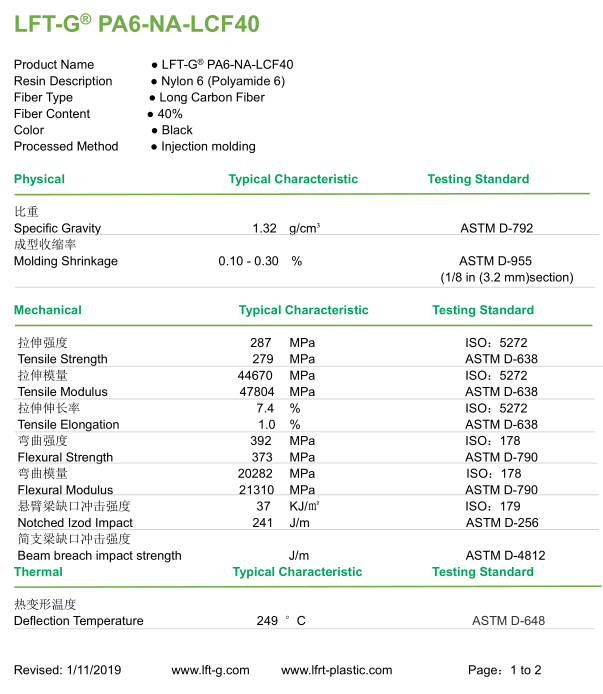

7-15 days after shipmentPolyamide 6 (PA6) has chemical and physical properties very similar to PA66. However, differences in molecular structure lead to distinct performance characteristics. PA6 features a lower melting point and a wider processing temperature window, offering better impact resistance and solubility resistance than PA66, while also exhibiting higher moisture absorption.

Since many quality characteristics of plastic parts are affected by hygroscopicity, molding shrinkage is largely influenced by crystallinity and moisture absorption. Therefore, these factors must be carefully considered when designing PA6 products.

Fiber-reinforced PA6 effectively reduces shrinkage and mitigates issues caused by moisture absorption. Its high crystallinity and excellent flowability contribute to improved dimensional stability and overall part performance.

Nylon products should be used with attention to dimensional deviation caused by thermal expansion and moisture absorption. Conventional PA6 also shows limited acid resistance and UV resistance. Long-term exposure to high temperatures may cause thermal oxidation, resulting in discoloration and eventual material degradation. Therefore, unmodified nylon is generally not recommended for outdoor applications.

Carbon fiber reinforced modified PA6 significantly improves creep resistance, rigidity, wear resistance, and mechanical strength, enabling stable performance in outdoor and demanding environments.

*Tip: Poor compatibility between carbon fiber and PA6 may lead to fiber floating and reduced mechanical properties. Xiamen LFT’s PA6 composites feature excellent fiber–matrix compatibility, effectively avoiding these issues.

Long carbon fiber reinforced PA6 enhances strength, heat resistance, impact resistance, and dimensional stability, making it suitable for both industrial and consumer applications.

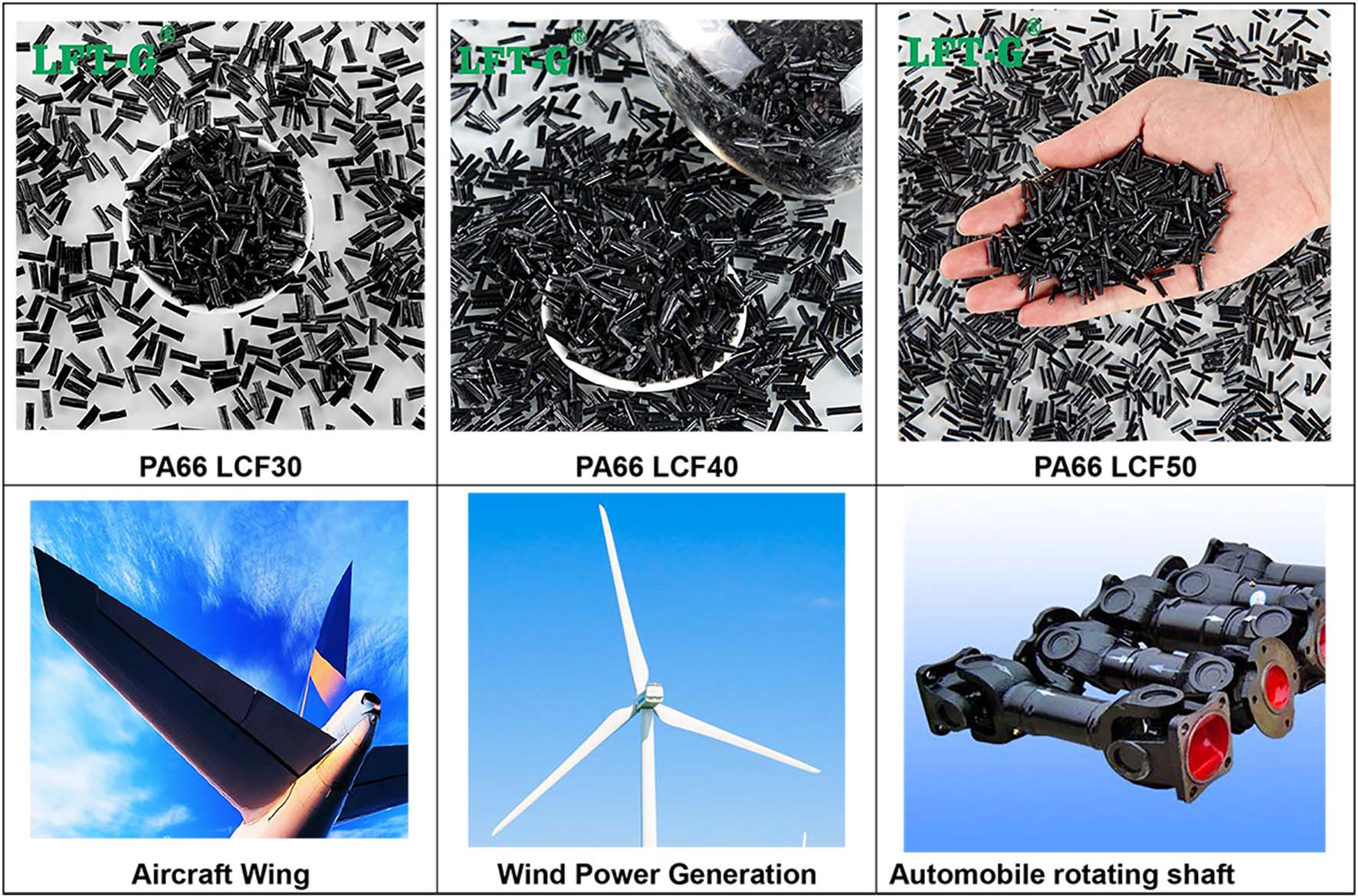

With trends toward lightweight and compact automotive design, under-the-hood temperatures continue to rise. Carbon fiber reinforced PA6 meets these demanding requirements and is widely used in automotive engine components, electrical systems, body structures, and airbag-related parts.

Due to its excellent mechanical properties, dimensional stability, heat resistance, and aging resistance, carbon fiber reinforced PA6 is also commonly applied in mechanical parts and aerospace equipment components.

Long carbon fiber reinforced PA6 features high flowability, high rigidity, excellent mechanical strength, low shrinkage, creep resistance, thermal stability, wear resistance, oil resistance, uniform fiber dispersion, and good surface gloss. Typical applications include power tools, fishing equipment, automotive parts, machinery components, and office accessories.

Related Tags :