item no.:

PPS-NA-LCFPayment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

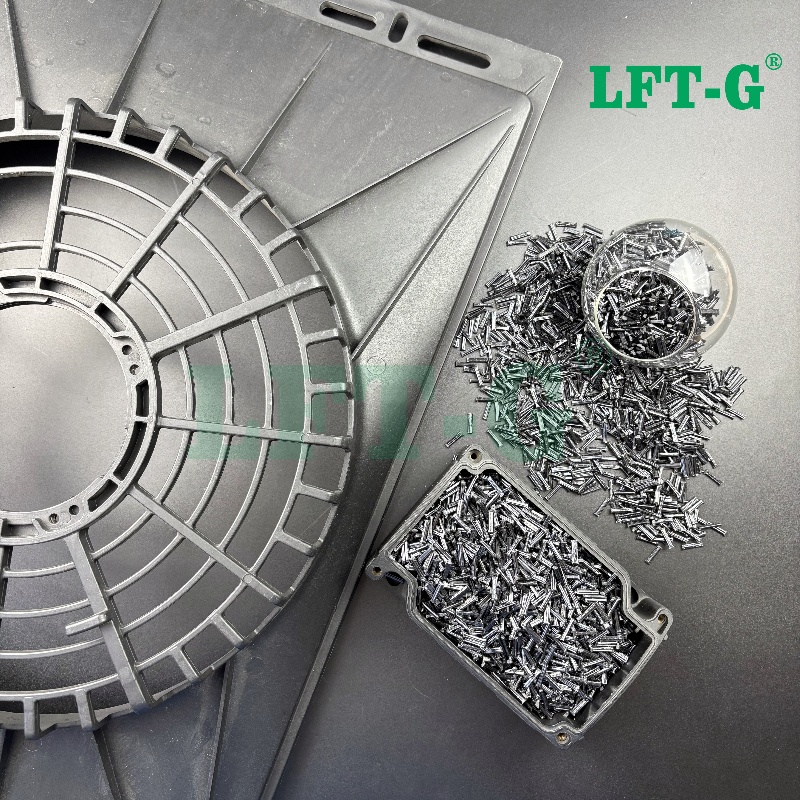

Xiamen, ChinaPolyphenylene Sulfide (PPS) is a high-performance, semi-crystalline engineering plastic with a rigid aromatic backbone. It offers an outstanding balance of heat resistance, chemical stability, dimensional precision, and electrical performance, making it one of the top materials in the engineering plastics performance pyramid.

PPS can operate continuously at 200–240°C, with reinforced grades reaching HDT values up to 260°C. It maintains mechanical strength even under long-term thermal stress.

PPS resists most acids, alkalis, fuels, oils, and solvents below 200°C. Its corrosion resistance is comparable to PTFE.

High rigidity, surface hardness, creep resistance, and fatigue resistance. Wear performance improves further with carbon fiber or lubricant fillers.

Stable dielectric properties under high temperature and humidity. PPS grades typically meet UL94 V-0 without added flame retardants.

Used in electric drive units, fuel systems, cooling modules, and sensor housings. Replaces metal and thermosets while reducing weight and processing cost.

Ideal for gears, bearings, and sliding components in printers and copiers due to low friction and dimensional accuracy.

Connectors, coil bobbins, SMT components, and high-temperature insulation parts requiring flame resistance and precision molding.

PPS provides insulation, thermal resistance, and chemical stability for battery structural parts and insulation components.

PPS fiber is widely used in high-temperature dust filter bags for steel plants, power stations, and waste incinerators.

| Item | Details |

|---|---|

| MOQ | 20 KG |

| Sample | Available |

| Packaging | 20 KG / Bag |

| Port of Loading | Xiamen Port |

| Lead Time | 7–15 Days After Shipment |

| Color | Customized |