-

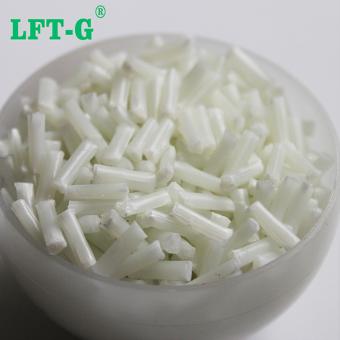

LFT PPS long glass fiber thermoplastic composite granulesPPS long glass fiber reinforced thermoplastic granules for introduction and properties

- glass fiber pps thermoplastic material

- pps fiber molding

- pps lgf glass fiber

- natural color pps lgf composite

- PPS polymer glass fiber pellets

- thermoplastic virgin granules PPS

Tags :

-

environment reinforced thermoplastic material HDPE lgf compoundHDPE modified pellets injection production material.

- HDPE enhance mateiral

- HDPE modified long fiber pellet

- High density polyethylene compound

- natural color LFT HDPE long glass fiber

- Composite injeciton mold virgin HDPE pellet

- Long glass fiber reinforced hdpe lgf

Tags :

-

Thermoplastic Polyurethane TPU LGF filling composite industry productProduct number: TPU-NA-LGF Product fiber specificaion: 20%-60% Product features: High toughness, High toughness, Low water absorption, High dimensional stability, chemical resistance, good product appearance.

- Low water absorption

- footwear

- Columnar particle

- Natural color

- Industrial supplies

- Sample available

Tags :

-

Thermoplastic reinforced PBT-LGF glass fiber resin plasticProduct grade: General grade Fiber specification: 20%-60% Product feature: High toughness, Low warpage Product application: Electronic appliances, Machinery parts etc.view more

-

LFT-G Polypropylene PP reinforced materials long glass fiber filled high mechanical properites for home appliance partsPP filling Long glass fiber PP (polypropylene), as one of the general-purpose plastic materials, has a large production volume and low price, as well as excellent comprehensive performance, good chemical stability, and better molding and processing performance. However, the shortcomings of PP, such as low strength, low service temperature, low hardness, and poor low-temperature impact strength, have seriously limited its application areas. Therefore, engineers by adding glass fiber, calcium carbonate and other reinforcing materials in PP, and when the length of the glass fiber and other lengths exceed the critical size, the mechanical properties are improved by leaps and bounds! Long Glass Fiber Reinforced PP (LFT-PP) is a very typical thermoplastic composite material, which is generally a column of particles with a length of 12 mm to 25 mm and a diameter of about 3 mm. In these particles, the glass fibers have the same length as the particles, the content of glass fibers can vary from 20% to 70%, and the color of the particles can be matched according to customer requirements. PP-LGF advantages 1. longer fiber length, significantly improve the mechanical properties of the products. 2. high strength, good impact resistance, especially suitable for furniture, automotive parts. 3. high creep resistance, good dimensional stability, high precision parts molding. 4. excellent fatigue resistance. 5. better stability in high temperature and humid environment. 6. molding process fiber can be in the molding mold relative movement, fiber damage is small. LGF VS SGF Application Automotive industry: front-end module, door module, gearshift mechanism, electronic gas pedal, instrument panel frame, cooling fan and frame, battery tray, bumper bracket, underbody protection plate, sunroof frame, etc., used to replace reinforced PA or metal materials. Home appliance industry: washing machine drum, washing machine triangle bracket, air conditioner fan, etc., used to replace short glass fiber reinforced PA, ABS or metal materials. Communication, electronics, electrical industry: communication electronics industry, high-precision connectors, ignition components, coil shafts, relay base, microwave oven transformer coil frame / frame, electrical connectors, solenoid valve package, scanner components, etc.. Others: power tool shells, water pump or water meter shells, impellers, bicycle skeletons, skis, ground locomotive pedals, military/civilian safety helmets, safety shoes, such as the head of the package, used to replace the short fiberglass-reinforced PA, PPO and so on. Produce processing Certification About us Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- LFT-G homopoymer plastic PP

- PP injection molded lgf natural color

- Polypropylene composite plastic modified

- pp gf30 for electrical connector price

- PP pellets lgf 30 polymer

- PP car parts use factory made

Tags :

-

Thermoplastic Polyurethane TPU LGF filling composite industry productProduct number: TPU-NA-LGF Product fiber specificaion: 20%-60% Product features: High toughness, High toughness, Low water absorption, High dimensional stability, chemical resistance, good product appearance.

- Low water absorption price good

- footwear shoes uses

- Columnar particle safty plastic

- Natural color images sa

- Industrial supplies film automotive

- Sample available tpu 3d printing

Tags :

-

Xiamen LFT-G Thermoplastic resin reinforced PBT Long glass fiber addition high qualityProduct grade: General grade Fiber specification: 20%-60% Product feature: High toughness, Low warpage Product application: Electronic appliances, Machinery parts etc.

- PBT resin high mechanical properties

- Electronic appliances composites

- sample available pbt

- Natural color widely applications

- Fiber filling material compounds

- High toughness industry use

Tags :

-

LFT-G Polyamide 66 with addition long glass fiber 20%-60% reinforced plastic as a replacement for metalWhat is Polyamide 66 materials? PA66, abbreviation of Polyamide 66, chemical name polyhexanediylhexanediamine, commonly known as nylon 66. It is a colorless transparent semi-crystalline thermoplastic polymer, widely used in automotive, electrical and electronic appliances, mechanical instruments and meters, industrial parts and other industries. However, due to the high water absorption, poor acid resistance, low impact strength in dry state and low temperature, and easy to deform after absorbing water, which affects the dimensional stability of the products, the scope of its application has been limited to a certain extent. In order to improve the above shortcomings, expand its field of application, and better meet the requirements for the use of performance, people use a variety of methods to modify PA66, in order to improve the impact, heat deformation, molding and processing performance and chemical corrosion resistance of PA66 plastic. As the specific strength and Young's modulus of glass fiber (GF) is 10-20 times larger than PA66, the coefficient of linear expansion is about 1/20 of PA66, the water absorption rate is close to zero, and there is good heat and chemical resistance, etc., so the glass fiber filling is the most commonly used means of enhancement and modification of PA66. Polyamide 66 fillin long glass fiber compounds Why do we use LFT plastics instead of metal? Many components that are currently manufactured in metal can be produced at lower cost and lower weight in high strength plastics. Compared to metals, plastics offer a number of significant advantages: • Faster production cycles • Lower investment in equipment and tooling • Elimination of finishing operations, such as machining or painting • No corrosion problems • Tighter tolerances • Easier assembly What is the difference between Long glass fiber and Stardard glass fiber? Long glass fiber (LGF) typically contain glass fibers with lengths of 10 to 12 mm, versus 0.7-mm fibers in standard glass-reinforced compounds. In the composite material made of fibers is sheared or pulled, the fibers are pulled out from the matrix, such a pulling process is conducive to the absorption of energy provided by the loading, the longer the fibers are within a certain length, the greater the absorption of energy, and the more significant its strength. And in the same volume amount, due to the longer the single fiber, the fewer the number of fiber roots, the less stress concentration generated at the fiber end, the more difficult the destruction of the material. From the results of practical application feedback, the various properties of long glass fiber reinforced thermoplastic composites are more excellent than Standard glass fiber. In addition, glass fiber reinforced composites in the friction process, the fiber body plays an important role in lubrication, long glass fiber can be much more sustainable, stable lubrication, so the coefficient of friction is lower, less wear, and the formation of the abrasive debris is finer. Because of these advantages, long glass-fiber reinforced thermoplastic composites perform better in real-world applications without fear of high frequencies and high loads. What is the advantages of Polyamide 66? Nylon 6/6 is composed of a molecular structure of higher order than Nylon 6, heightening Nylon 6’s positive characteristics: higher tensile strength and stiffness, better dimensional stability, and a higher melting point. Nylon 6/6 has a high lubricity and resistance to hydrocarbons; and exceptionally balanced strength, ductility, and heat resistance. As strong as it is independently, adding fillers, fibers, lubricants, and impact modifiers can increase Nylon 6/6’s strength times five and stiffness times ten. TDS of 30% long stand fiber glass reinforced Polyamide 6.6 All TDS with 20%-60% fiber specification, please aks technologists What are the applications of Nylon 66 filling long stand fiber glass pellets? Frequently asked questions Q. Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. Q. Using a long fiber reinforced thermoplastic material, will it block the die hole due to the long length of the fiber or not? A. When using long glass fiber or long carbon fiber, it is necessary to evaluate whether the product is suitable for LFT-G. If the product is too small or the dispensing is not suitable for long fiber materials. The long fiber itself has requirements for mold nozzle. Q. How to choose the rei...

- engineering thermoplastics PA66

- long glass fiber reinforced thermoplastic resin pa66

- heat deflection temperature pa66 gf

- Nylon 66 comounds more dystaline

- injection molded high stiffness and tensile

- gf filled plastic pa66 natural color

Tags :

-

LFT-G Polyamide 12 long carbon fiber filled modified nylon12 high impact resistance and toughnessLong carbon fiber Carbon fiber has many excellent properties, high axial strength and modulus, low density, high specific performance, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, good X-ray transmission. Good electrical and thermal conductivity, good electromagnetic shielding, etc. Compared with traditional glass fiber, carbon fiber has more than 3 times of Young's modulus; it is about 2 times of Young's modulus compared with Kevlar fiber, which is insoluble and swollen in organic solvents, acids and alkalis, and has outstanding corrosion resistance. But is there a way to reduce the price of carbon fiber? That is to mix it with relatively cheap nylon material to form a composite material with good performance and meet the requirements. In that case, there is no doubt that carbon fiber nylon will definitely have a place in the composite material. Nylon itself is an engineering plastic with excellent performance, but moisture absorption, poor dimensional stability of products. Strength and hardness are also far from metal. In order to overcome these shortcomings, as early as before the 70s. People have used carbon fiber or other varieties of fibers for reinforcement to improve its performance. Carbon fiber reinforced nylon materials have developed rapidly in recent years, because nylon and carbon fiber are excellent performance in the field of engineering plastics materials, its compound material synthesis reflects the superiority of the two, such as strength and rigidity than unreinforced nylon is much higher, high temperature creep is small, thermal stability has improved significantly, good dimensional accuracy, wear resistance. Excellent damping, compared with glass fiber reinforced has better performance. Therefore, carbon fiber reinforced nylon (CF / PA) composites have developed rapidly in recent years. And for 3D printing using SLS technology is the most suitable technical means to achieve carbon fiber reinforced nylon. TDS for reference Application Our company Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- long fibre reinforced thermoplastics resin pa12

- carbon fiber reinforced plastics granules

- long carbon fiber reinforced pa12

- thermoplastic Polyamide 12 natural color with addition fiber

- wear resistance injection molding pa12 gf

- pa12 lcf for car parts

Tags :

-

Xiamen LFT-G Polybutylene terephthalate contain long glass fiber reinforced PBT compoundsProduct grade: General grade Fiber specification: 20%-60% Product feature: High toughness, Low warpage Product application: Electronic appliances, Machinery parts etc.

- PBT resin great mechanical strength

- Electronic appliances use PBT-GF instead metal

- sample available PBT self factory made good price

- Natural color PBT filling LGF 20%-60%

- Fiber filling material injection molded PBT

- High toughness and strength PBT fiberglass

Tags :

-

LFT PPS long glass fiber reinforcement thermoplastic composite granulesPPS long glass fiber reinforced thermoplastic granules for introduction and propertiesview more

-

Xiamen LFT-G reinforced PBT plastic Long glass fiber polymers high qualityProduct grade: General grade Fiber specification: 20%-60% Product feature: High toughness, Low warpage Product application: Electronic appliances, Machinery parts etc.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文