-

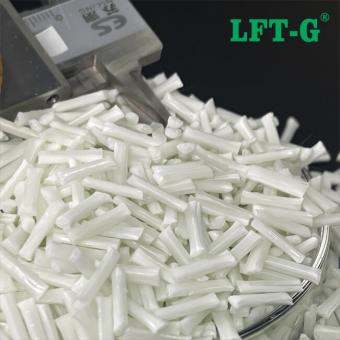

Long Fiber Thermoplastic with Bio-Based PLA MatrixPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- Bioplastic composite PLA

- eco-friendly high-strength PLA

- 3D printing filament materials

- biodegradable PLA glass fiber composite

- PLA long fiber for 3D printing

- Glass fiber PLA compound

Tags :

-

Engineering-Grade MXD6 LFT Material for Automotive & ElectronicsMXD6 Nylon - MXD6 is a kind of crystalline polyamide resin, which is synthesized by the condensation of m-benzoylamine and adipic acid. The advantages of nylon MXD6 1. In a wide range of temperature, maintain high strength, high rigidity 2. High thermal deformation temperature and small thermal expansion coefficient 3. Low water absorption rate, small size change after water absorption, less mechanical strength reduction 4. Forming shrinkage rate is very small, suitable for precision forming processing 5. Excellent coating, especially suitable for high temperature surface coating 6. Oxygen, carbon dioxide and other gases also have excellent barrier Application of MXD6 in plastic modification industry MXD6 can be combined with fiberglass, carbon fiber, mineral, and/or advanced fillers for use in fiberglass reinforced materials containing 50-60% and for exceptional strength and stiffness. Even when filled with high glass content, its smooth, resin-rich surface produces a fibre-free high gloss surface, ideal for painting, metal-plating, or creating naturally reflective shells. 1. suitable for high liquidity of thin wall It is a very fluid resin that can easily fill thin walls as thin as 0.5 mm thick even when the glass fiber content is as high as 60%. 2. Excellent surface finish A resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content. 3. High strength and stiffness The tensile and flexural strength of MXD6 is similar to that of many cast metals and alloys with the addition of 50-60% glass fiber reinforced material. 4. good dimensional stability At ambient temperatures, the linear expansion coefficient (CLTE) of MXD6 glass fiber composites is similar to that of many cast metals and alloys. Strong reproducibility due to low shrinkage and the ability to maintain tight tolerances (length tolerances as low as ± 0.05% if properly formed). Datasheet Tested by our own lab, for reference only. laboratory & Warehouse Frequently asked questions 1. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 2. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the products, it needs to be evaluated in combination with specific products. 3. Are there any special process requirements of long carbon fiber injection molding products? A. We must consider the requirements of long fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long fiber is a relatively high cost materiaql, and need to evaluate the cost performance problem in the selection process. Main materials Why choose us 1. Integration of R&D, production and sales 2. Customized products, one-to-one pre-sales and after-sales service 3. Passed a number of system certifications, and product quality is stable 4. Five warehousing centers nationwide to meet customers' high-volume needs 5. Testing is available in an independent laboratory with technical experts with 30 years of experience 6. Sold globally to Asia, Europe, North America, Middle East

- high performance MXD6

- MXD6 composite for drone frames

- MXD6 replacement for metal

- long fiber reinforced thermoplastics

- high stiffness thermoplastics for UAV

- China MXD6 long glass fiber supplier

Tags :

-

LFT-G™ Premium Long Carbon Fiber Reinforced Homopolymer Polypropylene (PP) for High-Performance ApplicationsOur Long Carbon Fiber PP is a high-performance polypropylene composite, engineered for exceptional strength and lightweight properties, making it ideal for demanding applications like automotive parts.

- Carbon fiber reinforced polypropylene

- Carbon Fiber PP for Automotive

- Lightweight Carbon Fiber plastic

- Long Carbon Fiber plastic

- Carbon Fiber Reinforced Polypropylene

- High-Performance PP

Tags :

-

Nylon Materials LFT Carbon Fiber Modified Polymer PelletsPA6 Long Carbon Fiber Reinforced Composite is a high-performance engineering material composed of a polyamide 6 (PA6) matrix reinforced with long carbon fibers. It delivers outstanding mechanical strength, rigidity, and fatigue resistance, while maintaining excellent dimensional stability and thermal performance.

- materials nylon

- pa cf filament

- pa plastic material

- different kinds of carbon fiber

- strength carbon fiber

- long fiber

Tags :

-

LFT Polyamide 66 Plastic Carbon Fiber Modified Polymer ResinPA66 Long Carbon Fiber Reinforced Composite is a superior engineering material made from a polyamide 66 (PA66) matrix reinforced with continuous long carbon fibers. It offers exceptional tensile strength, impact resistance, and high thermal stability, along with excellent chemical resistance and dimensional precision under demanding conditions.

- pa6.6 cf

Tags :

-

PPS High Temperature Resistance with Glass FiberPPS long carbon fiber reinforced materials combine excellent mechanical strength, high thermal stability, and outstanding chemical resistance. They are ideal for precision parts used in high-temperature, corrosive, or high-stress environments.

- pps resin suppliers

- long fiber compounds

- carbon fiber reinforced thermoplastic

- lft g for automobile market

- applications of polymers in aerospace engineering

- carbon thermoplastic

Tags :

-

LFT Long Fiber PEEK High Mechanical Properties Plastic for DroneLFT long carbon fiber reinforced PEEK material offers unmatched strength, stiffness, and exceptional resistance to high temperatures and chemicals. Its superior durability and dimensional stability make it ideal for demanding aerospace, automotive, and industrial applications, where performance and reliability are crucial.view more

-

LFT PLA Manufacturer Carbon Fiber filled Compounds green materialsPLA long carbon fiber reinforced materials offer improved strength, stiffness, and dimensional stability compared to standard PLA, while maintaining its biodegradability. They are ideal for eco-friendly applications requiring lightweight and enhanced mechanical performance.

- PLA recycled

- automotive thermoplastic composites

- pla green materials

- PLA Carbon

- carbon fiber pellets

- can pla be recycled?

Tags :

-

Carbon Fiber PPS Plastic High Impact Resistance for EngineeringLFT long carbon fiber reinforced PPS material combines superior thermal stability and high mechanical strength, making it perfect for high-performance applications. Its excellent resistance to wear, chemicals, and high temperatures ensures long-lasting reliability in challenging environments.

- pps plastic

- carbon fiber reinforced plastic

- what is pps

- pps cf

- pps properties

- modified plastic

Tags :

-

High Performance PPS GF Glass Fiber Reinforced Thermoplastic PolymersPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats. PPS-LGF compounds PPS plastic (polyphenylene sulfide), English name: Polyphenylenesulfide, is a thermoplastic special engineering plastic with excellent comprehensive properties. Its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties. The product will make a metallic sound when it is dropped to the ground. . Pure PPS is rarely used alone due to its brittle performance. Most of the PPS used is its modified variety. Glass fiber reinforced PPS is one of them. PPS lengthened glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, and good product appearance. It can be used in water heater impellers, pump casings, joints, valves, chemical pump impellers and casings, cooling water impellers and Shells, home appliance parts, etc. Automotive industry Applications: Due to its excellent mechanical properties, thermoplastic carbon fiber is widely used in the automotive field of fuel system components, sensors, shell components. On the one hand, it is because of the high strength and stiffness of PPS-LCF, and the finished parts are not easy to damage. On the other hand, PPS-LCF also has a relatively low coefficient of thermal expansion to ensure the stability of the finished product. In addition, PPS-LCF also has very good corrosion and heat resistance, making the application life of the finished product longer. Industrial Applications: In the industrial field, it is mainly used in the parts of equipment, such as chemical processing equipment, air pumps, gaskets, valves, etc. In addition to the high strength of the PS-LCF, it is also because the parts made by the PS-LCF have very good self-lubricating properties, which is very important for mechanical parts. Therefore, compared with the traditional carbon fiber material products, the performance has been greatly improved. The wide range of applications of PPS-LCF include aerospace, automotive manufacturing, electronic equipment, chemical and medical fields. Basic Performance of PPS-LGF 1 Excellent overall performance. PPS resin is a crystalline polymer with high hardness. Its crystal content is about 65% and its density is 1.34g/cm^3. It has excellent mechanical properties. Its tensile strength and bending strength are better than those of PA, PC, PBT, etc. It has extremely high rigidity and creep resistance. The mechanical properties will better after adding glass fiber reinforcement. 2 Excellent heat resistance. Its melting point can reach 275~291℃, and its heat distortion temperature is 135℃. After glass fiber reinforcement, its heat distortion temperature can reach 260℃. In air, polyphenylene sulfide reaches the weakening temperature at about 400°C, and polyphenylene sulfide begins to decompose in air at 700°C. The long-term use temperature is 200~240℃, and the thermal stability of long-term continuous use is better than all current engineering plastics. 3 The dielectric strength is better. PPS has a symmetrical molecular structure, non-polarity, and low water absorption, so its electrical insulation is very good. Compared with other engineering plastics, its dielectric constant is small, and its arc resistance is equivalent to that of thermosetting plastics. It can be used in high temperature, high humidity, frequency conversion, etc. Under harsh conditions, PPS can still maintain excellent electrical insulation. 4 preservative. Because PPS has a high degree of crystallinity, it has excellent chemical resistance and is insoluble in any organic solvent below 200°C. In addition to strong oxidizing acids, it can withstand the erosion of various acids, alkalis, and salts. After being soaked in various chemicals for a long time, it still maintains high strength. Materials Details Number PPS-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermopl...

- Glass fiber reinforced plastic

- pps gf

- plastic pps

- pps supplier

- what is the difference between pps and ppa

- pps pellets

Tags :

-

Homo Polypropylene Glass Fiber Polymer Wide ApplicationsPolypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- fiber glass resins

- gfrc glass fiber reinforced concrete

- properties of fiber glass

- metal replacement solutions

- what is homopolymer and copolymer

- China PP supplier

Tags :

-

High Toughness Polyamide 6 Glass Fiber Polymer Wide ApplicationsWhen molding nylon 6, the material is sometimes injected with a specified amount of glass fibers (usually between 20% and 60%) to boost its tensile strength. Glass fibers improve stiffness.

- pa6 filament

- pa plastic

- polyamide and nylon

- Engineering thermoplastics supplier

- replacement for metal

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文