-

pp long glass fiber polypropylene homopolymer injectionpp long glass fiber recycle pellets for car parts,washing machine parts.

- pp pp injection grade

- pp raw materials

- pp filling

- High Toughness PP

- pp granules fiber reinforced pp

- pp gf30 pellets

Tags :

-

pp long glass fiber polypropylenepp long glass fiber Polypropylene chips;

- Polypropylene PP Pellets

- raw materials PP resin

- Glass fiber filled

- Long fiber reinforced thermoplastics PP

- Polypropylene granules fiber reinforced pp

- pp gf30 chips

Tags :

-

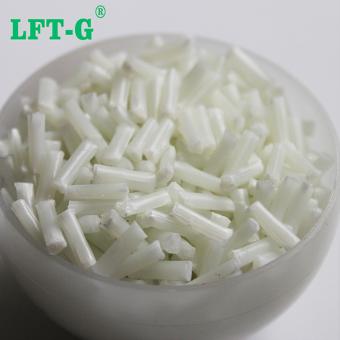

LFT Homopolymer PP Long Glass Fiber 30% Polypropylene MaterialsProduct Name:Homopolymer LGF30, Polypropylene LGF30, Polypropylene Long Fiber Thermoplastic Form: Length about 12mm, High strength, High toughness Advantage: More than 20 years experience product in fiber reinforced plastic .

- PP LGF30

- PP GF30

- LFT PP LGF

- Homopolymer PP Glass Fiber 20%

- Polypropylene Long Fiber Thermoplastic

- Polypropylene LGF30

Tags :

-

LFT-G PP Polyphenylene compounds long glass fiber thermoplastic resin original color sample availablePP fill Long glass fiber Advantages of glass fiber reinforced PP material in modified PP material. 1、The heat resistance temperature of glass fiber reinforced PP is much higher. 2、The shrinkage of glass fiber reinforced PP decreases a lot, and the rigidity is greatly improved. 3, glass fiber reinforced PP plastic, will not stress cracking, impact resistance improved a lot. 4、After glass fiber reinforced, the burning performance of PP plastic is reduced a lot. 5、After glass fiber reinforcement, the strength of PP is improved, such as: tensile strength, compressive strength, bending strength. The disadvantages of glass fiber reinforced PP material in modified PP material. 1、After glass fiber reinforcement, the transparency of the material decreases. 2、After glass fiber reinforced, the toughness of PP decreases and the brittleness increases. 3、After glass fiber reinforced, the hygroscopic property of PP is greatly enhanced, therefore, it should be dried when injection molding. 4、After glass fiber reinforcement, the melt viscosity of PP increases, the fluidity becomes worse, and the injection pressure increases a lot. 5、After glass fiber reinforcement, the fluidity of PP material is poor, and the injection temperature of reinforced plastic is increased by 10℃-30℃. 6、After glass fiber reinforced, attention should be paid to the surface corrosion treatment and surface hardness treatment of the equipment. 7、After glass fiber reinforcement, during the injection process, glass fiber can enter the surface of plastic products, making the surface of the products become rough. It is necessary to use the mold temperature machine to heat the mold when injection molding, so that the plastic polymer can enter the surface of the products and obtain a higher surface quality. TDS for reference only We have general grade, heat-resistance grade, UV-resistance grade, toughen-resistance grade for you to choose. Application General grade: Car parts, washing machine parts, water pump parts, water treatment components, furniture parts, etc. Heat-resistance grade: Car front and back module, water tank frame, battery bracket, engine cover, skylight frame, etc. UV-resistance grade: Car handle, car mirror parts, battery case, truck outside pedal etc. Toughen resistance grade: Power tools, pump shell, pipe fittings etc. LGF VS SGF Frequently askes questions Q. Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. Q. The causes and solutions for floating fibers for long glass fiber and long carbon fiber products. A. Due to the low temperature of the sol or the low temperature of the mold and the low injection molding pressure, the glass fiber and the resin can not be well compatible and diffused. The uneven temperature of the mold surface mold will cause the floating fiber problem, and can be solved by increasing the sol temperature, mold temperature and injection pressure. Q. Long glass fiber reinforced PP will reduce the toughness of the material and increase the brittleness. Is there any way to solve this problem? A. Long glass fiber and long carbon fiber will greatly enhance the impact and tensile strength of the substrate.

- Low warpage electronic appliance

- high strength and high toughness reinforced pp pellets

- best long glass fiber pp lgf30 granules

- pp gf30 for electrical connector price

- superior waterproof pp granules

- furniture polypropylene compounds lgf

Tags :

-

LFT-G Polypropylene PP reinforced materials long glass fiber filled high mechanical properites for home appliance partsPP filling Long glass fiber PP (polypropylene), as one of the general-purpose plastic materials, has a large production volume and low price, as well as excellent comprehensive performance, good chemical stability, and better molding and processing performance. However, the shortcomings of PP, such as low strength, low service temperature, low hardness, and poor low-temperature impact strength, have seriously limited its application areas. Therefore, engineers by adding glass fiber, calcium carbonate and other reinforcing materials in PP, and when the length of the glass fiber and other lengths exceed the critical size, the mechanical properties are improved by leaps and bounds! Long Glass Fiber Reinforced PP (LFT-PP) is a very typical thermoplastic composite material, which is generally a column of particles with a length of 12 mm to 25 mm and a diameter of about 3 mm. In these particles, the glass fibers have the same length as the particles, the content of glass fibers can vary from 20% to 70%, and the color of the particles can be matched according to customer requirements. PP-LGF advantages 1. longer fiber length, significantly improve the mechanical properties of the products. 2. high strength, good impact resistance, especially suitable for furniture, automotive parts. 3. high creep resistance, good dimensional stability, high precision parts molding. 4. excellent fatigue resistance. 5. better stability in high temperature and humid environment. 6. molding process fiber can be in the molding mold relative movement, fiber damage is small. LGF VS SGF Application Automotive industry: front-end module, door module, gearshift mechanism, electronic gas pedal, instrument panel frame, cooling fan and frame, battery tray, bumper bracket, underbody protection plate, sunroof frame, etc., used to replace reinforced PA or metal materials. Home appliance industry: washing machine drum, washing machine triangle bracket, air conditioner fan, etc., used to replace short glass fiber reinforced PA, ABS or metal materials. Communication, electronics, electrical industry: communication electronics industry, high-precision connectors, ignition components, coil shafts, relay base, microwave oven transformer coil frame / frame, electrical connectors, solenoid valve package, scanner components, etc.. Others: power tool shells, water pump or water meter shells, impellers, bicycle skeletons, skis, ground locomotive pedals, military/civilian safety helmets, safety shoes, such as the head of the package, used to replace the short fiberglass-reinforced PA, PPO and so on. Produce processing Certification About us Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- LFT-G homopoymer plastic PP

- PP injection molded lgf natural color

- Polypropylene composite plastic modified

- PP pellets lgf 30 polymer

- PP car parts use factory made

Tags :

-

Xiamen LFT-G Homopolymer Polypropylene with addition Long Glass Fiber componds higher strengthHPP is Homopolymer polypropylene

- Homopolymer Polypropylene HPP GF30

- High impact material polypropylene high

- PP plastic thermoplastic fiberglass

- Sample provide products polypropene

- 25kg/bag PP glass fiber filament

- Environmental friendly plastic

Tags :

-

Xiamen LFT Long glass fiber filled Polypropylene reinforced plastic pelletsGrade: General grade, Heat-resistant grade, UV-resistant grade, Toughen resistant grade Fiber specification: 20%-70% Product application: Industrial products, Household appliances, Automotive components and so on.

- general grade modified PP GF30

- Heat-resistant grade long cut PP polymers

- UV-resistant grade PP LFT for home appliances

- Toughen resistant grade PP with filler glass fiber

- Injection grade PP compounds instead metal

- Wide application range PP thermoplastic resin

Tags :

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.

- Compound plastic materials PP resin

- Polypropylene with long glass fiber

- pp filling glass fiber reinforced thermoplastic

- High strength modified material

- pp lgf lft PP GF30 high rigidity

- long glass fiber reinforced polypropylene

Tags :

-

Xiamen LFT reinforcement Polypropylene long glass fiber modifiedLong glass fiber reinforcement thermoplastic polypropylene resin

- Long fiber reinforced thermoplastics composite PP

- metal replacement PP polymer glass fiber reinforced

- High fatigue and creep endurance

- China manufacturer Polypropylene good price

- long glass fiber modified PP for car parts gfrp PP GF30

- higher performance than short/chopped glass fiber filled compounds.

Tags :

-

LFT-G Polypropylene PP reinforced long glass fiber high mechanical properites home appliance partsPP filling Long glass fiber PP (polypropylene), as one of the general-purpose plastic materials, has a large production volume and low price, as well as excellent comprehensive performance, good chemical stability, and better molding and processing performance. However, the shortcomings of PP, such as low strength, low service temperature, low hardness, and poor low-temperature impact strength, have seriously limited its application areas. Therefore, engineers by adding glass fiber, calcium carbonate and other reinforcing materials in PP, and when the length of the glass fiber and other lengths exceed the critical size, the mechanical properties are improved by leaps and bounds! Long Glass Fiber Reinforced PP (LFT-PP) is a very typical thermoplastic composite material, which is generally a column of particles with a length of 12 mm to 25 mm and a diameter of about 3 mm. In these particles, the glass fibers have the same length as the particles, the content of glass fibers can vary from 20% to 70%, and the color of the particles can be matched according to customer requirements. PP-LGF advantages 1. longer fiber length, significantly improve the mechanical properties of the products. 2. high strength, good impact resistance, especially suitable for furniture, automotive parts. 3. high creep resistance, good dimensional stability, high precision parts molding. 4. excellent fatigue resistance. 5. better stability in high temperature and humid environment. 6. molding process fiber can be in the molding mold relative movement, fiber damage is small. LGF VS SGF Application Automotive industry: front-end module, door module, gearshift mechanism, electronic gas pedal, instrument panel frame, cooling fan and frame, battery tray, bumper bracket, underbody protection plate, sunroof frame, etc., used to replace reinforced PA or metal materials. Home appliance industry: washing machine drum, washing machine triangle bracket, air conditioner fan, etc., used to replace short glass fiber reinforced PA, ABS or metal materials. Communication, electronics, electrical industry: communication electronics industry, high-precision connectors, ignition components, coil shafts, relay base, microwave oven transformer coil frame / frame, electrical connectors, solenoid valve package, scanner components, etc.. Others: power tool shells, water pump or water meter shells, impellers, bicycle skeletons, skis, ground locomotive pedals, military/civilian safety helmets, safety shoes, such as the head of the package, used to replace the short fiberglass-reinforced PA, PPO and so on. Produce processing Certification About us Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.view more

-

Xiamen LFT-G Homopolymer Polypropylene reinforced Long Glass Fiber compondsHPP is Homopolymer polypropyleneview more

-

Xiamen LFT long glass fiber reinforced PP Polypropylene materials injectionglass reinforced PP Polypropylene materials polymer long glass fiber 30% injection for car parts,washing machine parts.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文