-

PP excellent resistance to creep pp resin polypropylene lgf polymerexcellent resistance to creep pp resin polypropylene polymer which is producted in our factory.

- pp resin polypropylene

- recycled pp pellets

- pp pellets raw materials

- high strength and high toughness reinforced pp pellets

- pp polymer

- pp long glass fiber

Tags :

-

composite polypropylene plastic pp recycle granulescomposite polypropylene plastic pp recycle granules which one is made in ourself factory.The production is very cheap and the quality is very high.

- pp carbon fiber

- pp resin polymer

- pp modified materials

- pp cf30 plastics resin price

- pp pellets

- pp granules

Tags :

-

PP CF30 long carbon polymer composite materials homopolymerPP CF30 long carbon polymer composite materials which one is made in ourself industril.

- pp resin

- pp polypropylene injection molding

- composite polypropylene plastic

- polypropylenne pp pellets

- polypropylene impact copolymer injection

Tags :

-

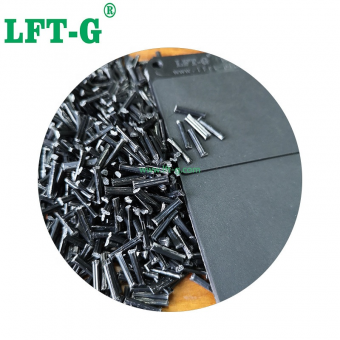

pp long glass fiber polypropylenepp long glass fiber Polypropylene chips;

- Polypropylene PP Pellets

- raw materials PP resin

- Glass fiber filled

- Long fiber reinforced thermoplastics PP

- Polypropylene granules fiber reinforced pp

- pp gf30 chips

Tags :

-

LFT PP Polypropylene long carbon fiber thermoplasticvirgin long carbon fiber pp polypropylene 94-V0 granules

- PP polypropylene homopolymer pellets

- long carbon fiber LFT thermoplastic

- black carbon fiber reinforced

- Flame-retardant PP Granules

- carbon fibre plastic pp pellets

- carbon fibre reinforced pp composite

Tags :

-

LFT-G Homo PP fill Long carbon fiber LGF 20-60 injection molding high toughness and strength 12mmWhat is the Homo PP? Homopolymerized PP plastics are made by polymerizing a single propylene monomer and do not contain ethylene monomer in the molecular chain. Homopolymerized polypropylene pp plastic has the advantage of better strength. Disadvantages are poor impact resistance (more brittle), poor toughness, poor dimensional stability, easy aging, and poor long-term heat stability performance. PP as a thermoplastic polymer began commercial production in 1957, is the first of the regulated stand-alone polymers. Its historical significance is further reflected in the fact that it has been the fastest growing major thermoplastic and has a very wide range of applications within the thermoplastic field, especially in fiber and filament, film extrusion, and injection molding processes. HPP-LCF Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. Its widespread use in aerospace and other advanced industries makes it a "high-tech" perception of consumers - you can use it to market products and create differentiation from competitors. Application You can contact us for more detailed information about application Datasheet for your reference Long carbon fiber Xiamen LFT composite plastic Co., Ltd Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.

- Low warpage electronic appliance

- self owing PP pellets

- pp cf40 for electrical connector price

- superior waterproof pp granules

- reinforced Polypropylene PP virgin pure materials

Tags :

-

LFT-G PP Polyphenylene compounds long glass fiber thermoplastic resin original color sample availablePP fill Long glass fiber Advantages of glass fiber reinforced PP material in modified PP material. 1、The heat resistance temperature of glass fiber reinforced PP is much higher. 2、The shrinkage of glass fiber reinforced PP decreases a lot, and the rigidity is greatly improved. 3, glass fiber reinforced PP plastic, will not stress cracking, impact resistance improved a lot. 4、After glass fiber reinforced, the burning performance of PP plastic is reduced a lot. 5、After glass fiber reinforcement, the strength of PP is improved, such as: tensile strength, compressive strength, bending strength. The disadvantages of glass fiber reinforced PP material in modified PP material. 1、After glass fiber reinforcement, the transparency of the material decreases. 2、After glass fiber reinforced, the toughness of PP decreases and the brittleness increases. 3、After glass fiber reinforced, the hygroscopic property of PP is greatly enhanced, therefore, it should be dried when injection molding. 4、After glass fiber reinforcement, the melt viscosity of PP increases, the fluidity becomes worse, and the injection pressure increases a lot. 5、After glass fiber reinforcement, the fluidity of PP material is poor, and the injection temperature of reinforced plastic is increased by 10℃-30℃. 6、After glass fiber reinforced, attention should be paid to the surface corrosion treatment and surface hardness treatment of the equipment. 7、After glass fiber reinforcement, during the injection process, glass fiber can enter the surface of plastic products, making the surface of the products become rough. It is necessary to use the mold temperature machine to heat the mold when injection molding, so that the plastic polymer can enter the surface of the products and obtain a higher surface quality. TDS for reference only We have general grade, heat-resistance grade, UV-resistance grade, toughen-resistance grade for you to choose. Application General grade: Car parts, washing machine parts, water pump parts, water treatment components, furniture parts, etc. Heat-resistance grade: Car front and back module, water tank frame, battery bracket, engine cover, skylight frame, etc. UV-resistance grade: Car handle, car mirror parts, battery case, truck outside pedal etc. Toughen resistance grade: Power tools, pump shell, pipe fittings etc. LGF VS SGF Frequently askes questions Q. Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber. Q. The causes and solutions for floating fibers for long glass fiber and long carbon fiber products. A. Due to the low temperature of the sol or the low temperature of the mold and the low injection molding pressure, the glass fiber and the resin can not be well compatible and diffused. The uneven temperature of the mold surface mold will cause the floating fiber problem, and can be solved by increasing the sol temperature, mold temperature and injection pressure. Q. Long glass fiber reinforced PP will reduce the toughness of the material and increase the brittleness. Is there any way to solve this problem? A. Long glass fiber and long carbon fiber will greatly enhance the impact and tensile strength of the substrate.

- best long glass fiber pp lgf30 granules

- pp gf30 for electrical connector price

- furniture polypropylene compounds lgf

Tags :

-

LFT main product Homopolymer PP polymer fill long glass fiber with high rigidity and tensile for sports partsWhat is the PP materials? Polypropylene (PP) is often referred to as the "steel" material of the plastics industry because it can be modified and customized to meet unique application requirements by adding additives to PP or by manufacturing it in unique ways. What is the Copolymer PP materials? Compared with PP homopolymer, copolymer polypropylene has improved optical properties, improved impact resistance, increased flexibility, lower melting temperature and thus also lower thermal fusion temperature; meanwhile, it is basically the same as homopolymer in terms of chemical stability, water vapor barrier properties and organ sensory properties. COPO-PP VS HOMO-PP COPO-PP Advantages: good overall performance, high strength, high rigidity, good heat resistance, good dimensional stability, excellent low temperature toughness (good flexibility), good transparency and good gloss. Disadvantages: Less heat resistant than homopolymer PP HOMP-PP Advantages: better strength. Disadvantages: poor impact resistance (more brittle), poor toughness, poor dimensional stability, easy aging, poor long-term heat stability performance. Both of them we can provide, just contact us if you need. Datasheet of COPO-PP Application of COPO-PP General grade: Car parts, washing machine parts, water pump parts, water treatment components, furniture parts, etc. Heat-resistance grade: Car front and back module, water tank frame, battery bracket, engine cover, skylight frame, etc. UV-resistance grade: Car handle, car mirror parts, battery case, truck outside pedal etc. Toughen-resistance grade: Power tools, pump shell, pipe fittings etc. Other application filed you can contact us for technical support. About Xiamen LFT composite plastic Co., Ltd. Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO99001&16949 system certification, and the products have obtained lots of national trademarks and patents. Part of laboratory We have impact strength test, density & melt flow rate test, heat defiection temperature test, vicat softening temperature test, and etc. Contact us nowview more

-

Xiamen LFT PPC reinforced long carbon fiber 12mm higher mechanical properties natural black best priceWhat is the PP-LCF? Polypropylene is a kind of polymer material with low cost, excellent performance and wide application. By carbon fiber reinforcement, the strength, heat deflection temperature and dimensional stability of polypropylene materials can be improved, which expands the application fields of polypropylene materials and is widely used in electronic appliances, automobiles and other fields. Especially in the automotive field, with the development of new energy vehicles and in the trend of automotive lightweighting, carbon fiber reinforced materials are more and more widely used in the automotive field. What is the advantages of PP-LCF? The modified polypropylene material reinforced by carbon fiber has a series of advantages such as light weight, high modulus, high specific strength, low coefficient of thermal expansion, high temperature resistance, heat and impact resistance, corrosion resistance, and good vibration absorption. The datasheet was test by us, for reference only. What is the application of PP-LCF? High mechanical performance Meet the design trend of new energy vehicles Lower density meets the demand for lighter weight vehicles Other materials you may wonder PA6-LCF PA12-LCF PPS-LCF Test Processing Certifications Quality Management System ISO9001/16949 Certification National Laboratory Accreditation Certificate Modified Plastics Innovation Enterprise Honorary Certificate Heavy metal REACH & ROHS testing Contact us

- Long carbon fiber Reinforced Polypropylene for electrial accessories

- self owing pp pellets

- ppo granules

- carbone fiber reinforced pp pellets

- pp modified granules manufacturer

- Long fiber reinforced thermoplastics PPO

Tags :

-

LFT-G PP Polyphenylene blends long carbon fiber thermoplastic resin original color sample available 12mmPP material Polypropylene fiber has remarkable performance. Compared with other fibers, polypropylene fiber has the lightest, warmest and most hydrophobic fiber properties. The density of polypropylene fiber is only 0.91g/cm3, which is the smallest among the five synthetic fibers and about 34% lighter than polyester fiber; the insulation rate of polypropylene fiber is 36.49%, which is the highest among the five synthetic fibers and 1.7 times that of polyester; the standard moisture regain rate of polypropylene fiber is almost zero, and the hydrophobic and moisture-conducting properties are the best. At the same time, polypropylene fiber has good acid and alkali resistance and heat aging properties. PP-LGF reinofrced material Long carbon fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. Its widespread use in aerospace and other advanced industries make it and a "high-tech" perception of consumers - you can use it to market products and create differentiation from competitors. Datasheet of PP-LCF Injection molding Aplication of PP-LCF More suitable for large parts and structural parts. Other application fields you can contact us for technical supports. Test 1. Heat Deflection Temperature Testing 2. Vicat Softening Temperature Testing 3. Tensile Testing 4. Flexural Strength Testing 5. Elongation Testing 6. Density Testing 7. Melt Flow Rate Testing 8. Impact Strength Testing. 9. Etc. Production process 1. The original carbon fiber is physically and chemically treated to remove impurities, improve surface activity, and enhance the mechanical properties and durability of the prepreg. 2. Add resin, curing agent, additives, etc. to form a formula to improve fluidity, hardness, and temperature stability. 3. The pretreated carbon fiber is placed on the machine and compounded with resin. 4. The machine solidifies the words and the two are fully bonded. 5. Cut into 5mm-24mm particles according to the needs of manufactured products。 Certification 1. Quality Management System ISO9001/16949 Certification 2. National Laboratory Accreditation Certificate 3. Modified Plastics Innovation Enterprise 4. Honorary Certificate 5. Heavy metal REACH & ROHS testing Frequently asked questions Q. What are the advantages of long carbon fiber materials? A. Thermoplastic LFT long carbon fiber material has high rigidity, good impact strength, low warpage, low shrinkage, electrical conductivity and electrostatic properties, and its mechanical properties are better than glass fiber series. Long carbon fiber has the characteristics of lighter and more convenient processing to replace metal products. Q. Are there any special process requirements of long carbon fiber injection molding products? A. We must consider the requirements of long carbon fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long carbon fiber is a relatively high cost material, and need to evaluate the cost performance problem in the selection process. Q. The cost of long fiber products is higher. Does it has a high recycling value? A. The thermoplastic LFT long fiber material can be recycled and reused very wellview more

-

lft-g PA66 compounds filled long carbon fiber 30% Polyamide66 reinforced plastic high rigidity and tensile strengthPA66 plastic Nylon is the common name for polyamide (PA), a generic term for thermoplastic resins containing repeating amide groups on the main chain of the molecule, including aliphatic polyamides, aliphatic-aromatic polyamides and aromatic polyamides. As the top five engineering plastics, nylon has an extremely wide range of industrial applications, mainly in the fields of automotive parts, mechanical parts, electronics and electrical appliances, cosmetics, adhesives and packaging materials. Among them, the largest production and most widely used are aliphatic polyamides, mainly nylon 66 and nylon 6. Nylon 66 (PA66) is a class of polyamides made by condensation of adipic acid and hexanediamine. Advantages: high strength, corrosion resistance, good wear resistance, and has excellent properties such as self-lubricating, flame retardant, non-toxic and environmental protection. Disadvantages: poor heat resistance and acid resistance, low impact strength in dry state and low temperature, large water absorption rate affects the dimensional stability and electrical properties of the products. PA66 filling Long Carbon Fiber (LCF) Carbon fiber is an inorganic polymer material with carbon content higher than 90% obtained by carbonization and graphitization of organic fibers. Advantages: light mass, high strength, high modulus, high temperature resistance, wear resistance, corrosion resistance, fatigue resistance, electrical and thermal conductivity, etc. Disadvantages: high cost, relatively difficult to infiltrate, poor transparency, etc. Carbon fiber composites are very useful structural materials, which are not only light and high temperature resistant, but also have high tensile strength and elastic modulus, and are indispensable materials for the manufacture of spacecraft, rockets, missiles, high-speed aircraft and large passenger aircraft. In transportation, chemical industry, metallurgy, construction and other industrial sectors, as well as sports equipment and other aspects have a wide range of applications. Datasheet for reference We can provide long carbon fiber filling from 20% to 60%. Different fiber specifications have different characteristics. Application More products you can contact us for technical supports. LCF VS SGF As the fiber length increases, the stiffness and strength of the composite material gradually increases, but the dimensional complexity gradually decreases and the productivity gradually decreases. Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher toughness than short fiber, and the tensile strength is increased by 0.5-1 times. Product details Number Length Color Sample Package MOQ Port of Loading Delivery time PA66-NA-LCF40 12mm (can be customized) Natural color (can be customized) Available 20kg/bag 1 ton Xiamen Port 7-15 days after shipment Xiamen LFT in the exhibitions We will offer you 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.

- high toughness plastic pp cf CFRP

- LFT-G PP resin modified best price

- PP made in China cf instead metal

- pp thermoplastic prepreg lightweight

Tags :

-

LFT-G Homo PP long carbon fiber filler polypropylene high mechanical properties sample available natural blackLong carbon fiber (LCF) Carbon fiber was first used in aviation, military and other fields, and later was cited in the production of racing car parts. In recent years, it began to come into the consumer market, and is also one of the materials that international manufacturers are keen on. Carbon fiber composite materials are characterized by very light, rigid, and can withstand the same pressure as steel, the cost is higher. However, the material is more durable and has a high recycling value, so it can save costs to a certain extent. Carbon fiber composites include carbon fiber powders, short fibers, long fibers, and long fiber reinforced composites. Long carbon fiber composites have better mechanical properties than short carbon fiber composites, but there are certain requirements for the injection molding machine and mold of the product. Carbon fiber has excellent mechanical properties and chemical stability, lower density than aluminum, higher strength than steel, is the highest specific strength and highest specific modulus among the high-performance fibers that have been produced in large quantities, and has the characteristics of low density, corrosion resistance, high temperature resistance, friction resistance, fatigue resistance, high electrical and thermal conductivity, low coefficient of thermal and wet expansion, etc. It is an important strategic material for the development of national defense and national economy. The characteristics of corrosion resistance, high temperature resistance and low coefficient of expansion make it an alternative material to metal materials in harsh environments; the electrical and thermal conductivity properties expand its application in the field of communications and electronics; as the highest specific strength (strength to density) and highest specific stiffness (modulus to density) among the high-performance fibers currently in mass production, carbon fiber is an important material for aerospace, wind power blades, new energy vehicles, transportation, sports and leisure, etc, Carbon fiber is an ideal material for aerospace, wind power blades, new energy vehicles, transportation, sports and leisure, and other fields with light weight needs. Xiamen LGT-G LCF compounds have the following appearance: Flat grain, very light weight, shows flawless finish, no floating fibers, bubbles, etc. The color is natural black and the length is around 6 to 25 mm. Application Datasheet for reference Homo-PP & Copo-PP PP is divided into homopolymer PP and copolymer PP according to the different types of monomers involved in polymerization. Homopolymer PP is made by polymerization of propylene monomer only, and there is only one kind of link in the polymer molecular chain, with high crystallinity and good mechanical properties and heat resistance. Copolymerized PP is mainly made of propylene monomer and ethylene monomer, and there are ethylene links in addition to propylene links in the polymer molecular chain, which has high impact resistance. HPP composites and CPP composites, both of them are available for us. Details Number Color Length Package Sample MOQ Port of Loading Delivery time HPP-NA-LCF Natural color, or customized 6-25mm 20kg/bag Available 20kg Xiamen Port 7-15 days after shipment Test Xiamen LFT composite plastic CO., Ltd. Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文