-

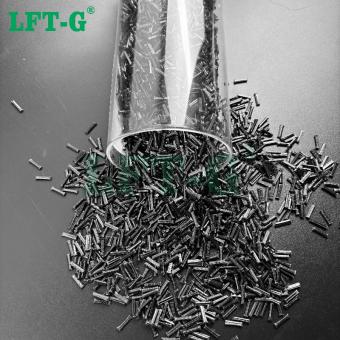

Poly(phenylene sulfide) PPS Toughness long carbon fiberLong carbon fiber Reinforced Poly(phenylene sulfide) PPS was prepared by impregnating and melting long carbon fiber with Poly(phenylene sulfide) PPS.

- Toughness Polyphenylene sulfide

- PPS reinforced

- Thermoplastics of long fiber reinforced

- PPS Polyphenylene sulfide Modified pps compound

- Engineering plastic materials PPS

Tags :

-

LFT-G PPS Polyphenylene sulfide LGF composite long glass fiber customized color engineering plasticsWhat is the PPS? Polyphenylene sulfide (PPS) is a new thermoplastic resin with high performance. By filling, modified with excellent high temperature resistance, corrosion resistance, wear resistance, flame retardant, balanced physical and mechanical properties and excellent dimensional stability and excellent electrical properties and other characteristics of the new high performance thermoplastic resin, as well as high mechanical strength, chemical resistance, flame resistance, good thermal stability, excellent electrical properties and other advantages. It has the advantages of hard and brittle, high crystallinity, inflammability, good thermal stability, high mechanical strength, excellent electrical properties, strong chemical corrosion resistance and so on. The mechanical properties of pure PPS are not high, especially the impact strength is relatively low. Good creep resistance under load, high hardness; High wear resistance, the wear at 1000 RPM is only 0.04g, and will be further improved after filling F4 and molybdenum disulfide; It also has a certain degree of self-moistening. The mechanical properties of PPS are less sensitive to temperature. What is the PPS-LGF? PPS is one of the best varieties of heat resistance in the engineering plastic department. The thermal deformation temperature of the material modified by glass fiber is generally greater than 260 degrees, and the chemical resistance is second only to PTFE. In addition, it also has small shrinkage, low water absorption, good fire resistance. Good resistance to vibration fatigue, strong resistance to arc, especially at high temperature. Excellent electrical insulation in high humidity. But its disadvantages are brittleness, toughness, low impact strength, after modification, can overcome the above shortcomings, obtain very excellent comprehensive performance. As a plastic, its properties and uses far exceed those of ordinary plastics, and in many ways it is as good as metal materials. Excellent material PPS has the advantages of high temperature corrosion resistance, excellent mechanical properties, can replace metal including stainless steel, copper, aluminum, alloy, etc., is considered to be the best substitute for metal, copper. What is the application of PPS-LGF? PPS is now widely used in automotive, aerospace, household appliances, mechanical construction and chemical industry for a variety of structural parts, transmission parts, insulation parts, corrosion resistant parts and seals. Under the condition of ensuring sufficient strength and other properties, the weight of the product is greatly reduced. Datasheet for reference Details Number Color Length MOQ Package Sample Delivery time Port of Loading PPS-NA-LGF30 Original color (can be customized) 5-25mm above 25kg 25kg/bag Available 7-15 days after shipment Xiamen Poer Production process Trademarks and patents Teams and customers We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.

- PPS Long glass fiber 40

- pps compounds lgf

- pps resin materials lft

- lft-g pps reinforced plastic

- long glass fiber filling pps

- termoplastic resin pps lgf

Tags :

-

LFT-G PPS Polyphenylene sulfide LGF composite long glass fiber customized engineering plasticsWhat is the PPS? Polyphenylene sulfide (PPS) is a new thermoplastic resin with high performance. By filling, modified with excellent high temperature resistance, corrosion resistance, wear resistance, flame retardant, balanced physical and mechanical properties and excellent dimensional stability and excellent electrical properties and other characteristics of the new high performance thermoplastic resin, as well as high mechanical strength, chemical resistance, flame resistance, good thermal stability, excellent electrical properties and other advantages. It has the advantages of hard and brittle, high crystallinity, inflammability, good thermal stability, high mechanical strength, excellent electrical properties, strong chemical corrosion resistance and so on. The mechanical properties of pure PPS are not high, especially the impact strength is relatively low. Good creep resistance under load, high hardness; High wear resistance, the wear at 1000 RPM is only 0.04g, and will be further improved after filling F4 and molybdenum disulfide; It also has a certain degree of self-moistening. The mechanical properties of PPS are less sensitive to temperature. What is the PPS-LGF? PPS is one of the best varieties of heat resistance in the engineering plastic department. The thermal deformation temperature of the material modified by glass fiber is generally greater than 260 degrees, and the chemical resistance is second only to PTFE. In addition, it also has small shrinkage, low water absorption, good fire resistance. Good resistance to vibration fatigue, strong resistance to arc, especially at high temperature. Excellent electrical insulation in high humidity. But its disadvantages are brittleness, toughness, low impact strength, after modification, can overcome the above shortcomings, obtain very excellent comprehensive performance. As a plastic, its properties and uses far exceed those of ordinary plastics, and in many ways it is as good as metal materials. Excellent material PPS has the advantages of high temperature corrosion resistance, excellent mechanical properties, can replace metal including stainless steel, copper, aluminum, alloy, etc., is considered to be the best substitute for metal, copper. What is the application of PPS-LGF? PPS is now widely used in automotive, aerospace, household appliances, mechanical construction and chemical industry for a variety of structural parts, transmission parts, insulation parts, corrosion resistant parts and seals. Under the condition of ensuring sufficient strength and other properties, the weight of the product is greatly reduced. Datasheet for reference Details Number Color Length MOQ Package Sample Delivery time Port of Loading PPS-NA-LGF30 Original color (can be customized) 5-25mm above 25kg 25kg/bag Available 7-15 days after shipment Xiamen Poer Production process Trademarks and patents Teams and customers We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.view more

-

LFT-G PPS Polyphenylene sulfide composite long glass fiber customized engineering plasticsWhat is the PPS? Polyphenylene sulfide (PPS) is a new thermoplastic resin with high performance. By filling, modified with excellent high temperature resistance, corrosion resistance, wear resistance, flame retardant, balanced physical and mechanical properties and excellent dimensional stability and excellent electrical properties and other characteristics of the new high performance thermoplastic resin, as well as high mechanical strength, chemical resistance, flame resistance, good thermal stability, excellent electrical properties and other advantages. It has the advantages of hard and brittle, high crystallinity, inflammability, good thermal stability, high mechanical strength, excellent electrical properties, strong chemical corrosion resistance and so on. The mechanical properties of pure PPS are not high, especially the impact strength is relatively low. Good creep resistance under load, high hardness; High wear resistance, the wear at 1000 RPM is only 0.04g, and will be further improved after filling F4 and molybdenum disulfide; It also has a certain degree of self-moistening. The mechanical properties of PPS are less sensitive to temperature. What is the PPS-LGF? PPS is one of the best varieties of heat resistance in the engineering plastic department. The thermal deformation temperature of the material modified by glass fiber is generally greater than 260 degrees, and the chemical resistance is second only to PTFE. In addition, it also has small shrinkage, low water absorption, good fire resistance. Good resistance to vibration fatigue, strong resistance to arc, especially at high temperature. Excellent electrical insulation in high humidity. But its disadvantages are brittleness, toughness, low impact strength, after modification, can overcome the above shortcomings, obtain very excellent comprehensive performance. As a plastic, its properties and uses far exceed those of ordinary plastics, and in many ways it is as good as metal materials. Excellent material PPS has the advantages of high temperature corrosion resistance, excellent mechanical properties, can replace metal including stainless steel, copper, aluminum, alloy, etc., is considered to be the best substitute for metal, copper. What is the application of PPS-LGF? PPS is now widely used in automotive, aerospace, household appliances, mechanical construction and chemical industry for a variety of structural parts, transmission parts, insulation parts, corrosion resistant parts and seals. Under the condition of ensuring sufficient strength and other properties, the weight of the product is greatly reduced. Datasheet for reference Details Number Color Length MOQ Package Sample Delivery time Port of Loading PPS-NA-LGF30 Original color (can be customized) 5-25mm above 25kg 25kg/bag Available 7-15 days after shipment Xiamen Poer Production process Trademarks and patents Teams and customers We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding.view more

-

LFT Polyphenylene sulfide Plastic Long Glass Fiber Reinforced CompositesPolyphenylenesulfide, is a thermoplastic special engineering plastic with excellent comprehensive properties. Its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties. The product will make a metallic sound when it is dropped to the ground.

- pps polyphenylene sulfide

- polymer pps

- pps compound

- pps charging

- pps chemical

- pps certification

Tags :

-

LFT-G PPS Polyphenylene sulfide LGF composite long glass fiber customized engineering plasticsPPS & PPS-LGF | High Performance Engineering Plastic body { font-family: Arial, Helvetica, sans-serif; line-height: 1.6; color: #333; } h2 { font-size: 24px; margin-top: 40px; } h3 { font-size: 20px; margin-top: 25px; } p { font-size: 16px; margin: 12px 0; } ul { font-size: 16px; margin-left: 20px; } table { width: 100%; border-collapse: collapse; margin-top: 20px; } table, th, td { border: 1px solid #000; } th, td { padding: 10px; text-align: center; font-size: 16px; } img { max-width: 100%; margin: 20px 0; } What Is PPS? Polyphenylene Sulfide (PPS) is a high-performance engineering thermoplastic known for its excellent heat resistance, chemical stability, flame retardancy, and mechanical strength. Through reinforcement and modification, PPS offers a well-balanced combination of physical, mechanical, and electrical properties. PPS features outstanding dimensional stability, corrosion resistance, and electrical insulation performance, making it suitable for harsh industrial environments. Key Characteristics of PPS Excellent high-temperature resistance High hardness and wear resistance Strong creep resistance under long-term load Excellent electrical properties over a wide temperature range Low sensitivity of mechanical properties to temperature changes Unmodified PPS is naturally brittle and has relatively low impact strength. These limitations can be effectively overcome through fiber reinforcement and material modification. What Is PPS-LGF? PPS-LGF refers to Polyphenylene Sulfide reinforced with Long Glass Fiber. Among engineering plastics, PPS-LGF stands out for its superior heat resistance, structural strength, and long-term reliability. Heat deflection temperature (HDT) above 260°C Chemical resistance second only to PTFE Low molding shrinkage and extremely low water absorption Excellent flame retardancy and vibration fatigue resistance Outstanding electrical insulation even in high humidity and high-temperature environments By incorporating long glass fibers, PPS-LGF significantly improves toughness and impact strength, overcoming the brittleness of pure PPS and delivering excellent comprehensive performance. In many applications, PPS-LGF can replace metals such as stainless steel, copper, aluminum, and alloys—making it an ideal material for metal replacement and lightweight design. Applications of PPS-LGF PPS-LGF is widely used in industries requiring high strength, heat resistance, and chemical stability, including: Automotive components Aerospace structures Household appliances Mechanical and structural parts Chemical processing equipment Electrical insulation and corrosion-resistant components Product Details Grade Color Pellet Length MOQ Packaging Sample Delivery Time Port of Loading PPS-NA-LGF30 Natural (Customizable) ≥ 5–25 mm 25 kg 25 kg / bag Available 7–15 days after shipment Xiamen Port Production Process Our PPS-LGF materials are produced using advanced long-fiber impregnation technology, ensuring excellent fiber length retention, uniform dispersion, and stable mechanical performance. Trademarks and Patents Our materials are supported by proprietary technologies, registered trademarks, and patented processes to ensure consistent quality and reliable performance. Teams and Customers Backed by an experienced R&D and production team, our PPS-LGF materials are trusted by customers worldwide across automotive, industrial, and electrical sectors. What We Offer LFT & LFRT material technical data and advanced design support Mold-front design recommendations and optimization Professional technical support for injection molding and extrusion processingview more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文