item no.:

ABS-NA-LGFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

ABS is a versatile engineering plastic known for chemical and thermal stability, strength, toughness, and glossy finish. It is widely used in consumer products such as toys and helmets, as well as automotive applications like interior trim, housings for electronics, and more.

Reinforcing ABS with glass fiber significantly improves rigidity, heat resistance, and dimensional stability. ABS-LGF composites provide excellent cost-performance balance, helping manufacturers reduce costs while meeting production needs.

1. Automotive Parts: Instrument panels, fenders, interiors, lights, mirrors, audio systems.

2. Electronic & Electrical Components: IT and OA equipment shells, converters, power sockets.

3. Electronic Appliances: Switches, controllers, monitors, housings, brackets.

4. Home Appliances: Electrical components, control boxes.

| Number | ABS-NA-LGF |

|---|---|

| Color | Natural or Customized |

| Length | 6-25 mm |

| Package | 25kg/bag |

| MOQ | 25kg |

| Lead Time | 2-15 days |

| Port of Loading | Xiamen Port |

| Trade Terms | EXW / FOB / CFR / CIF / DDU / DDP |

Founded in 2009, Xiamen LFT Composite Plastics Co., Ltd. is a leading global supplier of long fiber reinforced thermoplastic materials, integrating R&D, production, and marketing. Our products are ISO9001 & IATF16949 certified, patented, and applied in automotive, aerospace, medical, new energy, military, sports equipment, and more.

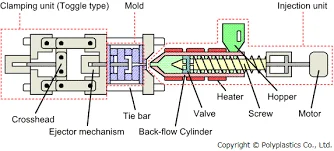

Compared to short fiber thermoplastics (1-2 mm fibers), our LFT materials (5-25 mm fibers) are fully impregnated with resin, ensuring superior mechanical performance. Base resins include PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Conventional fibers include glass and carbon fibers. Finished products can be used for injection molding, extrusion, or directly replace steel and thermoset components.