new blog

Today, additive manufacturing technology has enabled the formation of thermoplastic materials, metals, ceramics and photosensitive resins to meet the needs of different industries, such as aerospace, automotive or biomedical.

Current composite materials such as fiber reinforced composites can also be 3D printed. The reinforcement of composite materials, usually in the form of powder or filament, has better mechanical properties than the traditional polymer material monomer materials, such as lower density, higher stiffness and impact resistance, thus attracting more and more attention to the additive manufacturing of composite materials.

This article will provide advice from composite experts on how to integrate composite 3D printing in different production chains.

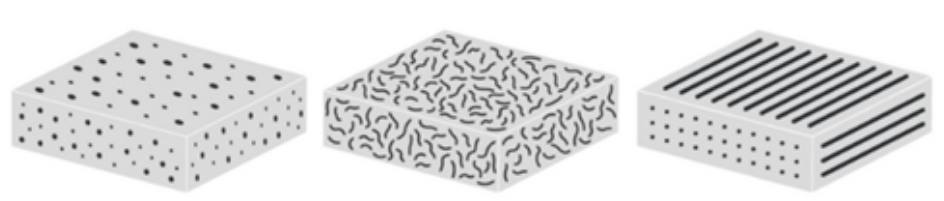

Composite with particles / Composite with short fibers / Composite with long fibers

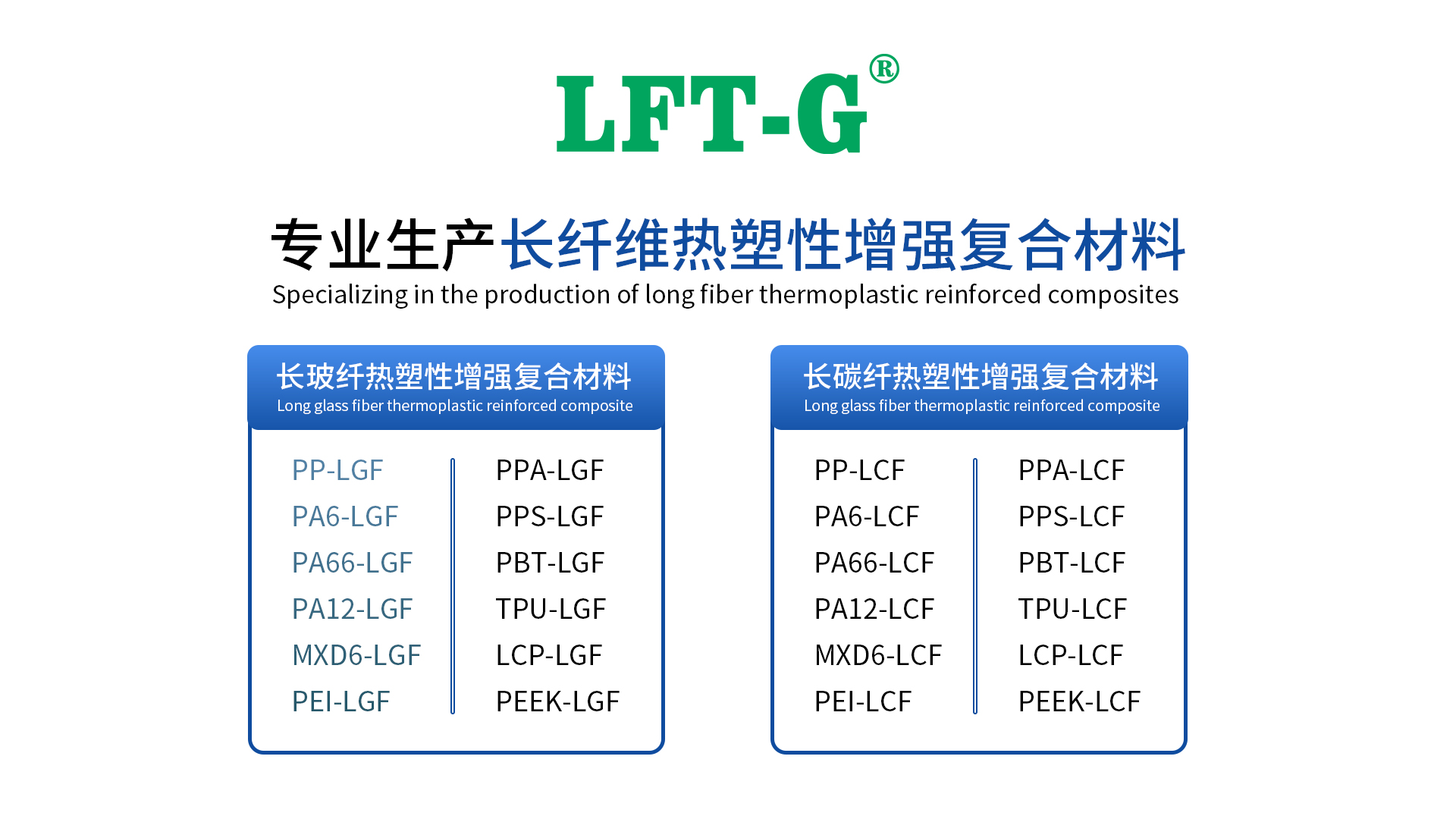

LGF&LCF Compounds

It is important to note here that the way 3D printing is also significantly different for different types of fibers.

The short fiber can be directly added to the matrix polymer material and prepared into silk after uniform distribution.

The addition of continuous long fibers requires separate printing and application, but requires the use of special 3D printers.

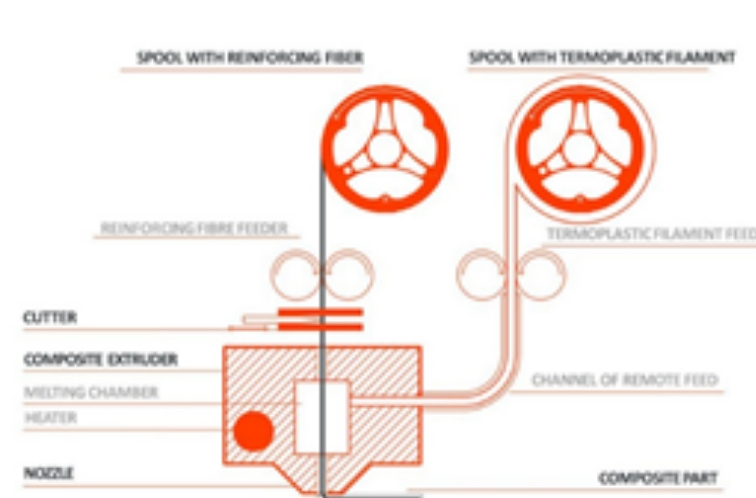

Compared to short fiber reinforcement materials that can be added to conventional polymers, continuous fiber composites are more expensive to produce but have superior properties. Composite materials of continuous fibers can be manufactured by a variety of methods, but usually need to be laid layer by layer by hand and require the use of expensive molds and curing equipment. The advantage of 3D printing is that the automatic preparation of composite materials can be achieved by sending continuous fibers and matrix materials respectively through two nozzles.

For the 3D printing process of composite materials, the matrix material and the fiber material together determine the printing process, considering that the current process has a very wide range of available materials, so most FDM printers can realize the printing of short fiber composite materials. However, for continuous fiber-reinforced composites, the common FDM process presents a greater challenge, because it involves a device that deposits continuous carbon fiber onto the substrate through a nozzle and cuts it as needed, in addition to the 3D printer setup is crucial. The direction of fiber extrusion directly affects the direction of fiber distribution, and also determines the mechanical properties of 3D printed composite materials. Therefore, the setting of the printer should also be carefully designed according to the mechanical properties of the required composite material. In contrast, the direction of fiber distribution in short fiber reinforced composites is relatively random, so the printing direction has little influence on the mechanical properties of short fiber reinforced composites.

FDM Print

3D printing of composite materials has the same advantages as 3D printing of other materials, shorter production time, less material consumption, and the possibility of more complex structures.

In addition, 3D printing of composite materials can regulate the performance of the printed part by designing how the fibers are distributed. This is especially true when printing with continuous fiber-reinforced composites. Under the same operating conditions, it can produce parts that are several times lighter than metal parts. Weight reduction is particularly important for high-performance applications such as aerospace, robotics, sports and healthcare, as lighter parts mean less energy consumption, lower transportation costs and higher quality products.

The use of 3D printed composites in the coming years will see significant progress in terms of size, productivity and mechanical properties. SmarTech market analysis indicates that the global composites market will grow by 22.3% over the next five years.

3D printing of continuous fiber composites still faces some challenges, but it also supports more flexible structural design to obtain composite components with better properties. For example, the performance can be optimized by fiber reinforced lattice structure, fiber steering, local reinforcement and other design methods combined with the actual application scenarios and load distribution of components.

Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.