new blog

Polyetheretherketone, commonly abbreviated as PEEK, is a high-performance engineering thermoplastic that belongs to the polyketone family. It is known for its excellent mechanical, thermal and chemical properties.

These properties make PEEK suitable for a wide range of applications. Uses include the aerospace, automotive, medical and electronics industries.

But do you know what makes it unique compared to other heat-resistant plastics?

Here's:

*The structure of PEEK and the reaction mechanism behind it

*Comparison of various PEEK versions of other heat-resistant plastics

*Suitable processing conditions and usable end products

What is PEEK - Polyetheretherketone?

Polyetheretherketone (PEEK) belongs to the family of polyketone polymers (PEK, PEEK, PEEKK, PEKK, PEKEKK). Of these, PEEK is the most widely used and produced on a large scale. It has been listed from ICI since the early 1980's. PEEK is a fully recyclable plastic.

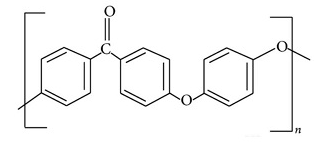

CAS No.: 29658-26-2

Chemical name: Poly(oxy-1,4-phenylene-oxy-1,4-phenylene)]

Chemical formula: C 19 H 14 O 3

Synthesis of PEEK

PEEK polymers are obtained by stepwise polymerization through dialkylation of bisphenol salts. It involves the reaction of 4,4'-difluorobenzophenone or 1,4-bis(4-fluorobenzoyl)benzene with hydroquinone. The reaction occurs in the presence of an alkali metal carbonate. The polymer is then isolated by removing the alkali metal fluoride and the polymerization solvent.

This polymer exhibits the highest thermal transition of any other commercial polymer. This is due to their stiff aromatic polymer backbone. As a result, they can be used at temperatures up to 240°C.

Typical Properties Overview

PEEK is a semi-crystalline, high-performance engineering thermoplastic. This rigid, opaque (gray) material offers a unique combination of

*Mechanical properties.

* resistance to chemicals and abrasion.

*Exceptionally high temperature resistance

*When combined with flexural and tensile properties, the polymer also exhibits excellent creep resistance. The material can withstand high loads at elevated temperatures* for extended periods of time without permanent deformation.

In addition to these properties, PEEK has:

*High melting point (Tm), 343°C

*High glass transition (Tg) temperature, 143°C

*High continuous operating temperature, up to 260°C

These properties make PEEK and its composites suitable for high-temperature applications. These include aerospace, automotive, structural, electrical and biomedical applications.

Despite the higher price of polymers, the added value that PEEK materials bring to manufactured parts includes:

* Lightweight.

*Strength or toughness, and

* the ability to survive longer in harsh environments.

The polymer exhibits high volume resistivity and surface resistivity. It maintains good insulating properties over a wide temperature range. It can also withstand environmental changes.

PEEK has a V0 flammability rating as low as 1.45 millimeters and an LOI of 35%. It has extremely low smoke and toxic gas generation. The crystallinity gives it excellent resistance to many fluids and superior fatigue properties.

PEEK is insoluble in all common solvents. It does not hydrolyze. It can be used for thousands of hours in steam or pressurized water with no noticeable loss of performance.

Additional properties of PEEK include:

*Low friction

*Good dimensional stability

*Excellent autoclave resistance

*Biocompatibility

*Long life

*Inherent purity

Performance Comparison: PEEK Versions and Other High-Temperature Resistant Polymers

Pure vs. Reinforced PEEK Versions

Carbon fiber reinforced PEEK grades offer excellent tensile properties. Tensile strengths of 29,000 psi are achieved and performance is maintained at 299°C. Reinforced grades offer improved performance at very high temperatures.

Reinforced grades increase flexural modulus at very high temperatures. Glass and carbon reinforcements can also be added:

*creep and fatigue resistance, the

*Thermal conductivity, and

*The heat deflection temperature of the polymer

Comparison of PEEK to Other High Temperature Resistant Plastics

*PEEKs exhibit excellent tensile strength, HDT, operating temperature, adhesion, processing and toxic gas emissions compared to fluoropolymers. However, they are inferior in chemical resistance, cost, toughness and UV weathering.

* Compared to PPS, PEEK has significantly superior heat resistance, toughness and spill resistance

*PEEK has higher temperature performance, abrasion resistance, chemical resistance and fatigue properties compared to PES.

*PEEK is not normally blended with other polymers. However, it can form miscible blends with a range of other polyketones and PEI PEEK/PEI blends have a high Tg and are highly compatible with PES and PPS blends.

Limitations of PEEK

*Expensive for demanding applications

*High temperature processing

*Attacked by certain acids, e.g. concentrated acid Sulfuric acid, nitric acid, chromium

*Attacked by halogens and sodium

*Low UV resistance

How are PEEK polymers processed?

Polyether ether ketone is processed by conventional methods such as:

*Injection molding.

*Extrusion

*Compression molding, etc.

However, the processing conditions used for molding affect crystallinity and mechanical properties.

As a linear thermoplastic, PEEK can be melt processed in the temperature range (370 to 420°C). No corrosive gases are generated when processing polyether ether ketone. Effective monitoring of the melting temperature of highly thermoplastic plastics improves product quality.

Before processing Polyetheretherketone, it is recommended to dry the material for 3 hours at 150°C or 2 hours at 180°C. This is to avoid any molding defects. This is to avoid any molding defects.

Processing of PEEK polymers:

Injection Molding

*A mold temperature of 160-190°C is recommended to obtain good crystallization and minimize warpage.

* Post-crystallization at 200°C is possible but not recommended for applications requiring high dimensional stability.

*PEEK is suitable for injection of very small parts with tight dimensional tolerances.

*Injection pressure: 70-140 MPa

*Molding Shrinkage: Unfilled - 1.2-2.4%, Filled - 0.1-1.1%

Extrusion

*Cooling temperature has a significant effect on crystallinity as well as properties.

*For film and sheet extrusion, a cooling cylinder of 50°C produces a clear amorphous material.

A cooling cylinder of *170°C will produce an opaque and highly crystalline material.

*Orbital or bi-oriented films can also be produced by the extrusion process.

3D Printing

With its unique properties, 3D printing of PEEK allows for the construction of virtually any complex design geometry that would be impossible to produce using other technologies. The Fused Deposition Modeling - FDM (or Fused Filament Fabrication - FFF) method is used for 3D printing using PEEK filaments.

*Nozzle temperature: 360-400°C

*Heated bed: 120°C

It is an excellent candidate for FFF due to its lower moisture absorption compared to other common FFF materials such as Acrylonitrile Butadiene Styrene (ABS).

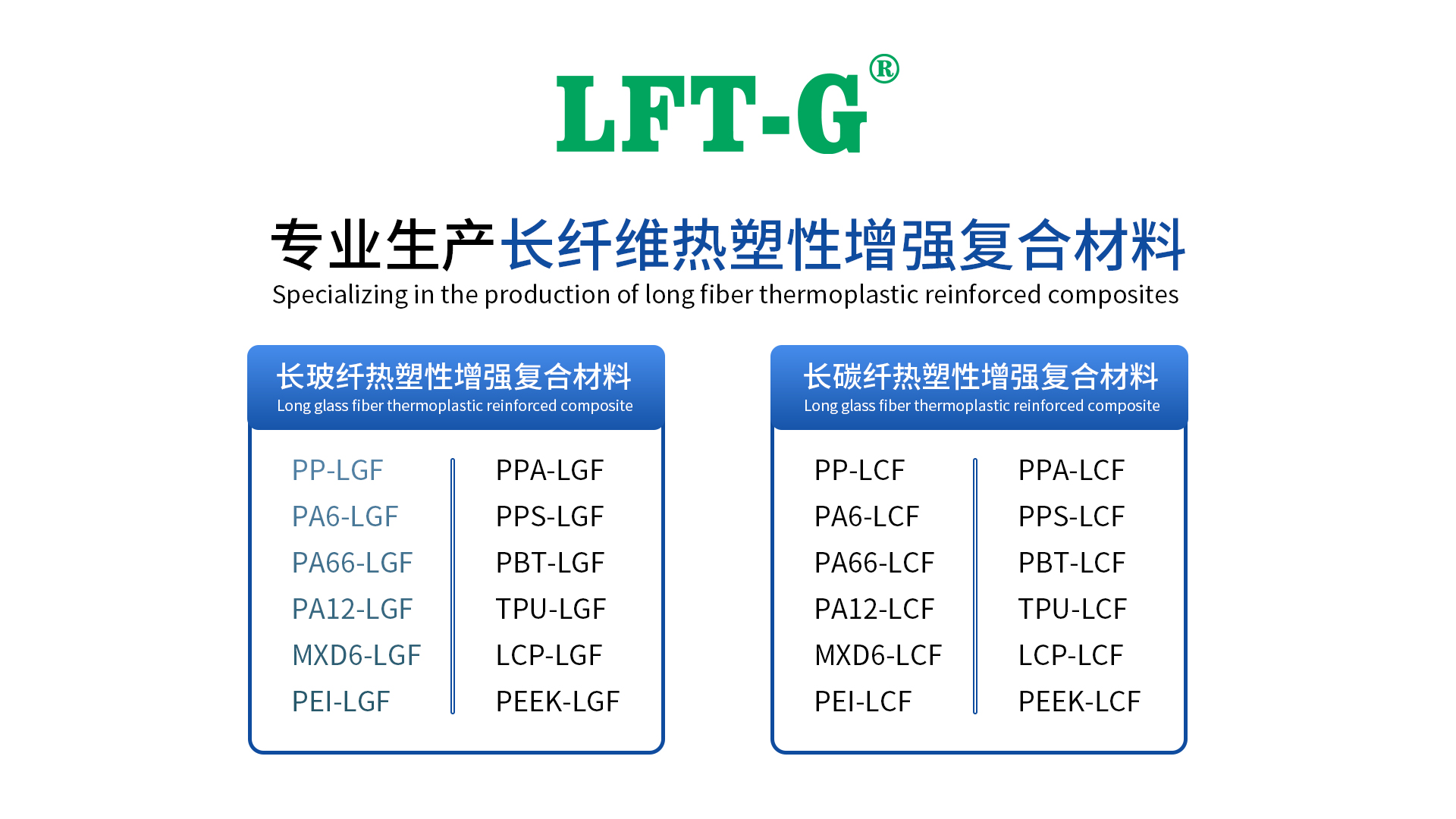

Xiamen LFT Composite Plastic Co,. Ltd.

Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.