new blog

Copolymers and homopolymers are distinct groups of polymers defined by the makeup and arrangement of their chemical structures. Homopolymers are distinguished by the fact that they are formed of one type of repeated monomer. Conversely, copolymers are made of at least two variants of monomers in any form of repeating pattern. While copolymers and homopolymers have some varying mechanical properties they mostly share the same applications, including: textiles, piping, car trim, films, and battery cases.

This article will discuss the differences between copolymer vs homopolymers, in terms of types, applications, advantages, and disadvantages.

What Is Homopolymer?

A homopolymer is a polymer in which all monomer units are identical. Polymers are a material which has a chemical structure consisting of a large chain of monomers. Some examples of homopolymers are polyvinyl chloride, which is constructed of multiple vinyl chloride units, and polypropylene, which is made of repeated propylene units.

What Is the Purpose of Homopolymer?

The purpose of homopolymers is to produce a polymer that has increased mechanical properties. These enhanced mechanical properties include: tensile strength, stiffness, impact resistance, and short-term creep resistance.

Where Are Homopolymers Used?

Homopolymers are used in a range of polymer manufacturing techniques including: injection molding, blow molding, thermoforming, and film, fiber, or sheet extrusion. These processes produce homopolymers for several industries including: automotive, packing, medical, consumer goods, and food containers.

Within these industries, the homopolymers' corrosion resistance makes them ideal for containers, tanks, and pipes. Its dimensional stability allows it to be used for gears and bearings. Homopolymer’s moisture resistance makes it a suitable choice for making clothes, carpets, fibers, and films.

What Are the Types of Homopolymer?

Homopolymers are classified by the fact that they are produced from a single variant of monomer, but each type of homopolymer may have a different monomer. The types of homopolymers include: polyvinyl chloride, polyethylene, polypropylene, polycarbonate, polyester, nylon 6, nylon 11, polytetrafluoroethylene, and styrene.

What Are the Advantages of Homopolymer?

The advantages of a homopolymer mainly lie in its mechanical properties, which are highlighted below:

High mechanical strength.

High stiffness.

High hardness.

High initial creep resistance.

Increased wear resistance.

Low rate of thermal expansion.

What Are the Disadvantages of Homopolymer?

The disadvantages of homopolymers are:

Poor ultraviolet resistance.

Poor acid or alkali resistance.

Poor thermo-oxidative stability.

Poor fire resistance.

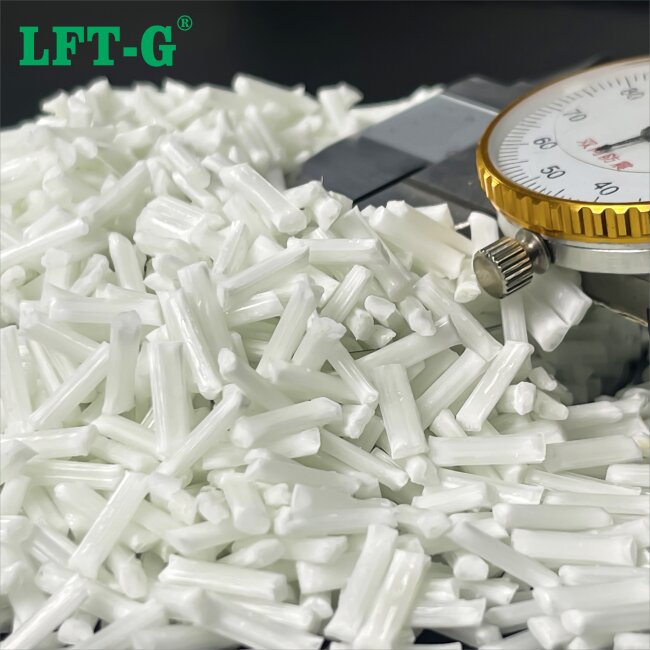

In view of the above shortcomings, Xiamen LFT introduced modified reinforced homopolymer materials. While having the advantages of homopolymer material, it overcomes the disadvantages.

(Homopoymer Polypropylene + Long glass fiber compounds)

What Is Copolymer?

A copolymer is a polymer made up of more than one type of monomer unit. Copolymers are produced by polymerizing two or more types of monomer together in a process referred to as copolymerization. Copolymers produced in this way are sometimes also referred to as biopolymers.

What Is the Purpose of Copolymer?

The purpose of creating a copolymer is to manufacture a polymer with more desirable properties. Copolymers typically experience a lower crystallinity, higher glass transition temperature, and improved solubility. These characteristics are achieved through a process referred to as rubber toughening.

Where Are Copolymers Used?

Copolymers can be found in many applications, including in: drug delivery, cosmetics, suncream, liquid membranes, emulsifiers, hoses, textiles, bearings gears, and self-polishing paint. Copolymers are commonly hygroscopic in nature, which accounts for some of the less-expected applications listed.

What Are the Types of Copolymer?

All copolymers may consist of two or more types of monomers. The different monomers can repeat singularly, in blocks, or in some other statistically repeatable way. Types of copolymers include: polyvinyl acetate, ethylene-vinyl acetate, high-impact polystyrene, acrylonitrile butadiene styrene, styrene-butadiene rubber, styrene-acrylonitrile rubber, styrene butadiene styrene, and polyethylene oxide.

What Are the Advantages of Copolymer?

The advantages of using copolymers include:

High shear resistance.

High operating temperature.

High corrosion resistance.

High impact resistance.

High dimensional stability.

What Are the Disadvantages of Copolymer?

There are some disadvantages to choosing copolymers over homopolymers, which are listed below:

Poor wetting characteristics.

Expensive.

Comparatively poor mechanical properties.

Copolymer Polypropylene + Long glass fiber compounds