The mechanical properties of blended materials such as glass fiber and toughening agent are added to nylon. The results show that with the increase of glass fiber content, the tensile strength and bending strength of the material are greatly improved, and the impact strength is more complicated. Adding, the toughness of the material is greatly improved. Adding 30% to 35% of glass fiber, 8% to 12% of toughening agent, the comprehensive mechanical properties of the material is the best.

1. GFR-nylon is a plastic (FR-PA) obtained by adding a certain amount of glass fiber to nylon resin for reinforcement. It can be divided into long glass fiber reinforced nylon (fibers and plastic particles equal length, generally about 12mm) made by the coating method, and mixed with chopped fiber, or continuous fiber is introduced into a twin-screw extruder for continuous shearing and mixing. The obtained short glass fiber reinforced nylon (the length of glass fiber is about 0.2~0.7mm).

2. Nylon is a polyamide and has amino groups in its main chain. Amino groups are polar and will attract each other due to the action of hydrogen bonds. Therefore, nylon is easy to crystallize and can be made into high-strength fibers. Polyamide is a tough, horny, translucent or milky white crystalline resin, often made into cylindrical pellets. The molecular weight of polyamide used for plastics is generally 15,000 to 20,000.

3. Compared with pure nylon, the mechanical strength, rigidity, heat resistance, creep resistance and fatigue strength of enhanced nylon are greatly improved, and the elongation, mold shrinkage, moisture absorption, and abrasion resistance are reduced

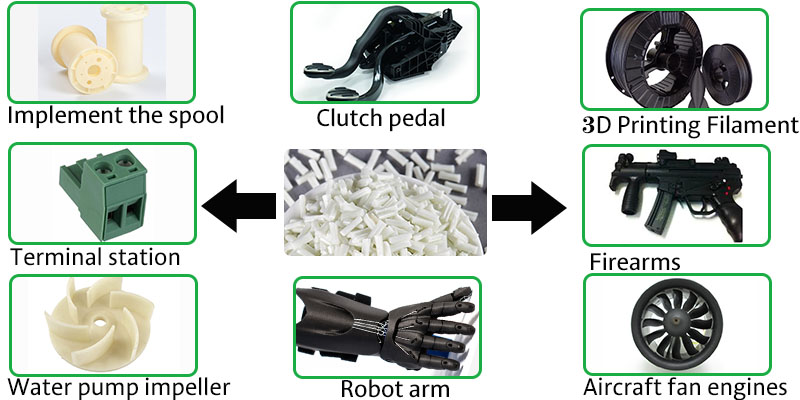

4. The performance is mainly determined by the bonding strength, content, aspect ratio and orientation of fiber and resin. It can be injection molded and extruded. Widely used in aerospace, automobile, machinery, chemical and other fields to manufacture heat-resistant structural plastic parts

5. When 30% glass fiber is added to PA, the mechanical properties, dimensional stability, heat resistance, and aging resistance of PA have been significantly improved, and the fatigue strength is 2.5 times that of unreinforced.

6. Use reinforcing materials to improve the performance of nylon. The reinforcing materials include glass fiber, which can improve the heat resistance, dimensional stability, rigidity, mechanical properties (tensile strength and bending strength) of nylon, especially the mechanical properties have been improved significantly, and become excellent performance Engineering plastics.

PA66 reinforced nylon series:

has excellent wear resistance, heat resistance and electrical properties, high mechanical strength, self-extinguishing, good dimensional stability, widely used in automotive industry products, pump impellers and first-class precision engineering components.

PA6 enhanced series:

has good abrasion resistance, heat resistance, oil resistance and chemical resistance, also greatly reduces the water absorption and shrinkage of raw materials, has excellent dimensional stability and excellent mechanical strength.