new blog

● What is the long fiber reinforced composite material (LFRT)?

It is a resin composite fiber material containing reinforcing fibers of length equal to the length of plastic pellets and greater than 6 mm in length.

●What are the benefits of using LFRT materials?

Benefits for business owners and factories.

a. Plastic instead of steel: In the past, metal was the material of choice for many industrial products because of its high strength and heat resistance, but the disadvantage is that it is not suitable for molding complex shapes. Long glass fiber reinforced material (L.F.R.T) has the most similar performance to metal, just like the best choice to replace metal.

b. Lightweight: The weight of metal parts is generally heavy, but with the global trend of advanced countries towards environmental protection/energy saving, the industry has started the trend.

c. High strength mechanical properties: For the parts made of LFRT, the long fibers form a three-dimensional 3D mesh structure inside and are staggered through the base resin as a reinforcement skeleton, so the parts can withstand greater stress and load, and effectively absorb external impact energy, thus making the finished products have excellent specific strength, rigidity, impact resistance, dimensional stability, as well as temperature resistance, low warpage, creep resistance, low coefficient of thermal expansion, etc. The result is a product with excellent specific strength, rigidity, impact resistance, dimensional stability, temperature resistance, low warpage, creep resistance, and low coefficient of thermal expansion.

●The use of LFRT contributes to environmental protection

Unlike general thermoset materials, LFRT is a thermoplastic material, and its offcuts can be recycled and crushed for reuse or re-blending without any significant loss of performance, and at the same time, it can reduce the cost of disposal of post-process waste.

●What are the benefits of using LFRT? What are the benefits to employees?

LFRT is a low VOC material and does not release any toxic substances compared to metal/thermoset material processing.

●What are the advantages of Xiamen LFT brand LFRT compared to other companies' products?

a. Computerized/automated European original process unit with stable quality and excellent resin-to-fiber adhesion.

b. We have a wide range of products, including PP, PA6, PA66, PA12, ABS, TPU, PPS, PPA, PBT, PEEK, etc. In addition to the regular general grades, we also produce flame retardant grades, toughened grades, heat resistant grades, UV resistant grades, etc.

c. Xiamen LFT's technical service team will assist customers throughout the process, such as specification suggestions, processing parameters, tooling, product applications, etc., to ensure that the performance of the material can meet customer requirements.

●What industries can LFRT be used in?

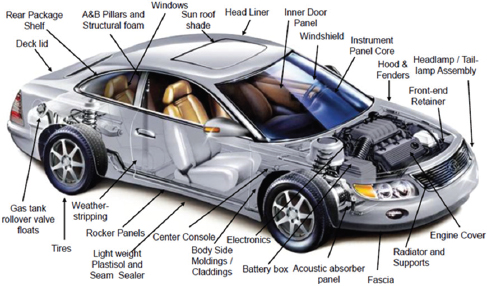

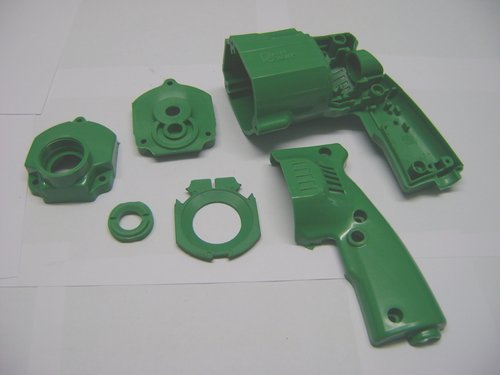

It is suitable for industries such as auto and motorcycle parts, hand tools, sports equipment (cycling/skiing/ fishing tackle/ treadmill), shoe parts, and industrial grade fans.

●Will the use of LFRT increase the cost?

a. The unit cost of material is slightly higher than that of aluminum alloy, but the secondary processing cost/time of metal can be saved, so it is relatively advantageous overall.

b. The unit cost of material is slightly higher than the same quality staple fiber reinforced compound, but the dimensional stability of LFRT is high, and it is not easy to deform, and it can be assembled after demolding.

●Will the appearance of molded products using LFRT be floating fiber?

The resin base material used for Xiamen LFT resin is high flowing resin, the appearance of the finished product is good, and the performance is even better if the mold temperature is added.

●Does LFRT wear out the injection molding machine screw?

The wear on the screw is mainly due to the sharp cross section at the ends of the fibers.

If you wantto know more about our materials, please contact us.

Wallis Wan

E-mail: sale02@lfrtplastic.com

Whatspp: +86 13950095727