new blog

Poly (butylene terephthalate) (PBT) is an excellent engineering material with excellent toughness, fatigue resistance, good heat resistance, good weather resistance, good electrical properties and low water absorption.

Modified PBT material is to enhance its flame retardant modification, so as to improve its heat resistance, flame retardant, dimensional stability and modulus, used in automotive, electronic and electrical industries.

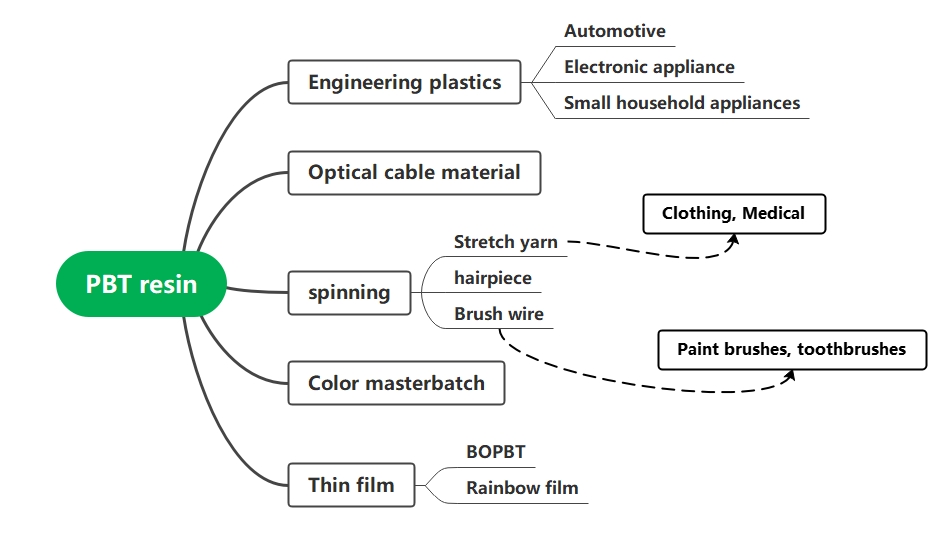

PBT Applications

The main uses of PBT resin are engineering plastics, optical cable materials and spinning fibers, accounting for about 92% of the total.

The specific application fields can be seen in the following figure:

Modification method of PBT material

Enhanced modification

Adding glass fiber to PBT is a common method of PBT enhancement modification. Glass fiber and PBT resin bonding force is good, after adding a certain amount of glass fiber to PBT resin, not only can maintain the original advantages of PBT resin chemical resistance, processability and so on, but also can greatly improve its mechanical properties, and overcome PBT resin notch sensitivity.

Flame retardant modification

PBT is a crystalline aromatic polyester, if no flame retardant is added, its flame retardant is UL94HB, only after adding flame retardant modification, can reach UL94V0 level. Commonly used flame retardants are halogen flame retardants such as bromide, Sb2O3, phosphide and chloride. Flame retardant modified PBT is mainly used in household appliances, electronic and electrical products with flame retardant requirements.

Blending alloy modification

The main purpose of blending PBT with other polymers is to improve the notched impact strength, improve the warping deformation caused by the forming process shrinkage, and improve the heat resistance.

PBT Application

Automobile industry

PBT has good chemical resistance, stress cracking resistance, wear resistance, weather resistance, aging resistance and high strength performance, and is widely used in automotive external parts, such as wiper handle bracket, bumper, door handle, rearview mirror shell, car bottom plate, body side panel, radiator fan, radar penetration cover, corner grilles and lighting components.

Electronic appliance

PBT is widely used in electronic and electrical fields because of its characteristics of low dielectric, low warpage, high flame retardant, high toughness, aging resistance and environmental protection. Such as electronic computer shell, igniter, electrical switch, photocopier, transformer skeleton, baking machine parts, iron cover and so on. In addition, because the modified PBT has excellent dielectric properties and is easy to process, it can be used in the bottom cover, shell and spool of electrical appliances.

Mechanical equipment

Due to its high flame retardant and heat resistance, PBT is widely used in the field of mechanical equipment, such as cams, gears, camera parts, electronic watch housings, mercury lampshades and all kinds of buttons. The common coil skeleton requires the material to have high insulation breakdown strength to avoid electrical breakdown during use; When it is applied to parts such as refrigerators, it also needs to have low precipitation to prevent small molecules from precipitating to make mechanical parts fail.

Communication field

PBT has been widely used in the field of communication because of its good dielectric property, processability, dimensional stability and low coefficient of linear expansion. In radio communication, Fe3O4 nanoparticles are added to PBT composite material to increase its consumption of electromagnetic waves to achieve magnetic shielding function, reduce the harm of electromagnetic radiation to the human body, and used as a plastic substrate for basic parts on high-power communication equipment.

Conclusion

In the plastics processing industry, PBT is mainly used in automotive manufacturing, electrical engineering/electronics industry and general applications.

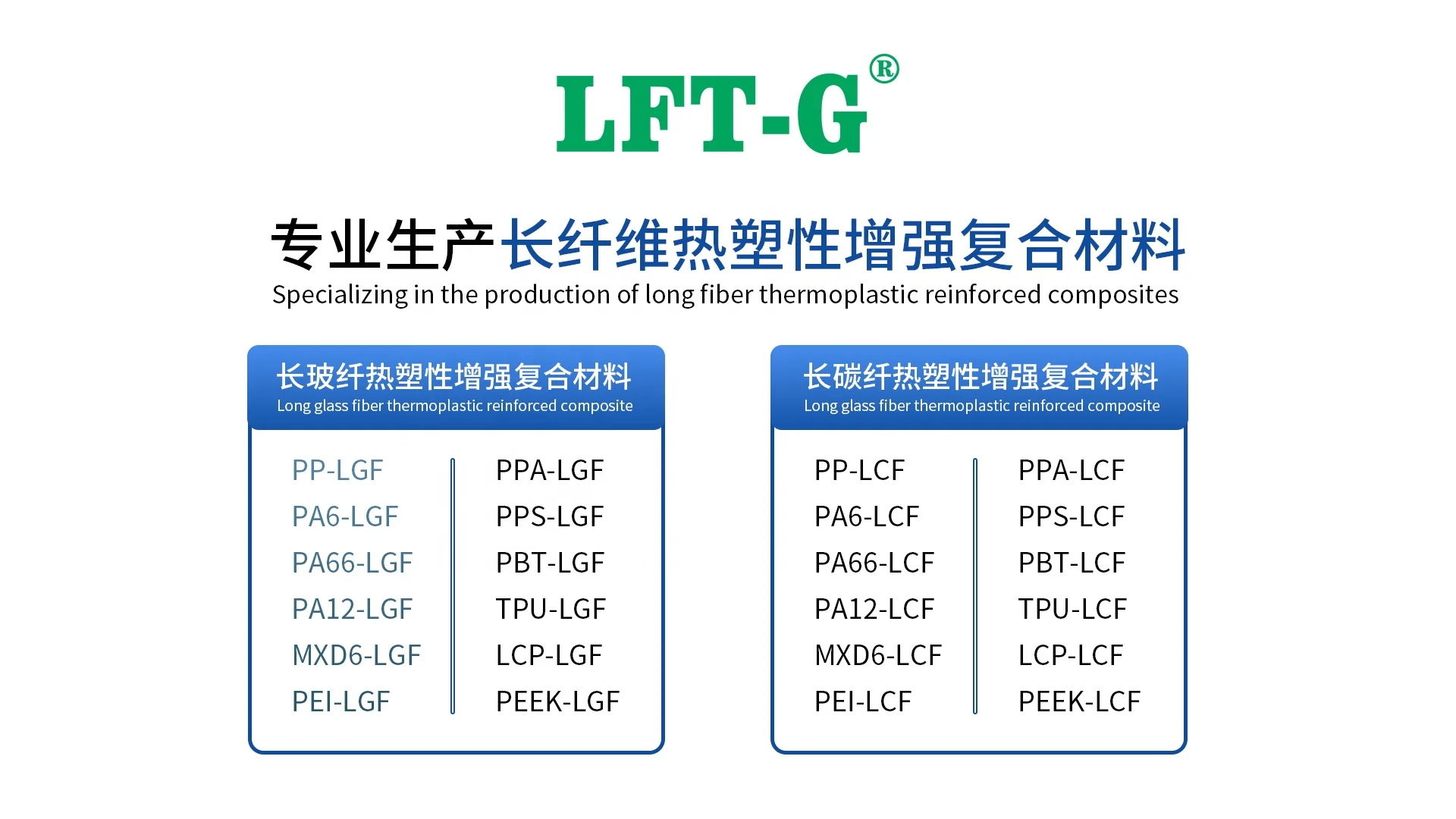

Xiamen LFT Composite Plastic Co., Ltd. Focusing on modified engineering plastics for more than 20 years, as a provider of engineering plastics solutions, product quality and service are highly recognized by customers.

We always adhere to the win-win business philosophy, in the product development, production, delivery and other core links, to continue to provide customers with quality services, to provide the most effective innovative service solutions!