new blog

In discussions about “replacing steel with plastic,” one critical concept is often overlooked: material performance should not be judged by absolute values alone.

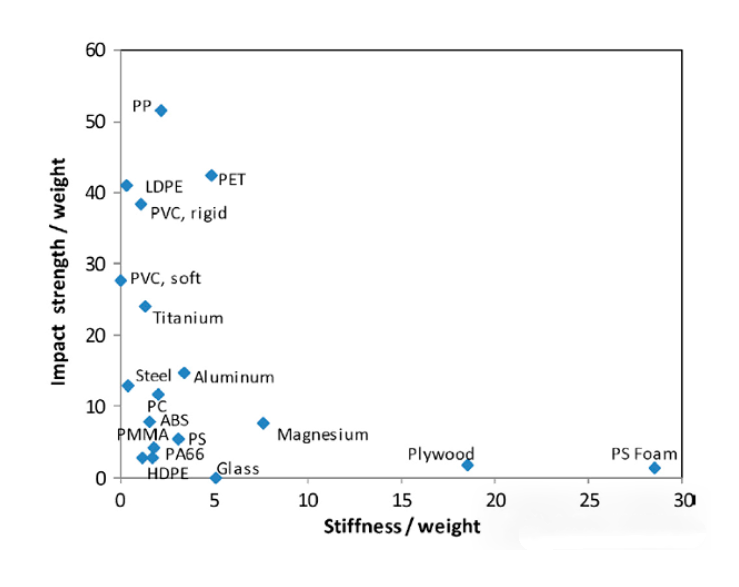

The real question is not “which material is stronger,” but: under the same weight constraint, which material delivers higher load capacity and stiffness?

This is exactly where specific strength and specific stiffness become essential.

Steel typically reaches 400–1000 MPa, while engineering plastics are usually 100–200 MPa. At first glance, they seem incomparable.

However, when strength is normalized by density, the comparison changes completely.

The maximum stress a material can withstand per unit weight. It determines load-bearing capacity under the same mass.

The stiffness a material provides per unit weight. It controls deformation under load, especially in brackets, housings, and frames.

Nearly 6× volume expansion allows ribs, reinforcements, and higher moments of inertia.

Result: Comparable stiffness and strength with 60–70% weight reduction.

The essence of “plastic replacing steel” is not imitation, but achieving a better specific-performance balance under weight-constrained design.