new blog

What is PA12-LCF?

PA12-LCF is a thermoplastic material, belonging to the nylon class. PA12-LCF is based on nylon 12, which has 12 carbon atoms in each polymer repeat unit. Nylon 12 is also known as polyamide 12 or PA12. It is a semi-crystalline material with a high melting point (180°C) and a low moisture absorption rate (0.5%). It is also resistant to chemicals, wear and impact.

PA12-LCF is a modified version of Nylon 12 reinforced with 20% to 70% carbon fiber by weight.

These materials differ from standard thermoplastic compounds in the length of the carbon fiber in the pellets. Retention of fiber length in the finished part is key to the performance of LFT. The carbon fiber is continuous within the pellet and offers incredible properties and performance when molded correctly.

LFT® is A LGF or LCF compound , through Centerfill manufacturing method which Offers exceptional Properties for weight and Cost reduction. With pellet length of 7-25mm and a range of 20%-70% of LGFor LCF content , LFT® Products family consist of Tailor made solutions to the Industry’s vast requirements , such as:

· LFT® - Fulfills heat stability requirements.

· LFT® - Offer Climate resistant Properties including UV resistance.

· LFT® - Ultra Performance & safety , with exceptional impact resistance Features, especially at low temperatures.

· LFT® - Cost Effective

P.s. Centerfill manufacturing method:Centerfill uses our proprietary technology to introduce glass roving (GFR), which consists of several thousand filaments, into an impregnating device and melt the thermoplastic resin, uniformly impregnating between the filaments and then cutting them into pellets. Manufacture.

What are the advantages of PA12-LCF?

PA12-LCF has many advantages that make it an attractive material for a variety of applications. Some of the key benefits include (using 30%LCF content as an example) :

High durability and hardness: the tensile strength of PA12-LCF is 241MPa, and its tensile modulus is 21973 MPa, which is much higher than that of pure nylon 12 (50 MPa and 1700 MPa, respectively). The bending strength of PA12-LCF is also 350 MPa and its bending modulus is 16,898 MPa, which is also higher than that of pure nylon 12 (80 MPa and 2000 MPa, respectively). These characteristics make PA12-LCF excellent in applications requiring high mechanical properties and strength.

Excellent heat resistance: PA12GF20 has a thermal deformation temperature (HDT) of 204°C (at 0.45 MPa), which is higher than pure nylon 12 (150°C at 0.45 MPa). This means that PA12-LCF can maintain its shape at higher temperatures without deforming or losing its performance.

Good chemical resistance: PA12-LCF is resistant to different types of chemicals such as oils, fats, fuels, solvents, acids, bases and salts. It also has the ability to resist hydrolysis, that is, it is not decomposed by water or moisture. This makes PA12-LCF suitable for applications in contact with harsh environments or liquids.

Good electrical conductivity: This makes PA12GF20 suitable for applications where electrical conductivity is required.

Good processing properties: PA12-LCF can be easily processed by different methods, such as injection molding, extrusion molding, 3D printing. PA12-LCF has a low viscosity and a wide processing window, which means that it can be injected at low temperatures and low pressures, while the processing cycle time is fast. In addition, PA12-LCF also has good fluidity and formability, which means that it is able to fill complex molds and produce parts with high precision and surface quality.

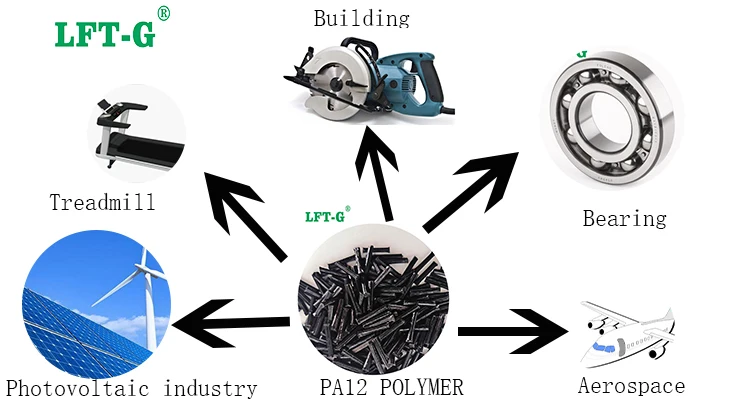

The main applications of PA12-LCF?