new blog

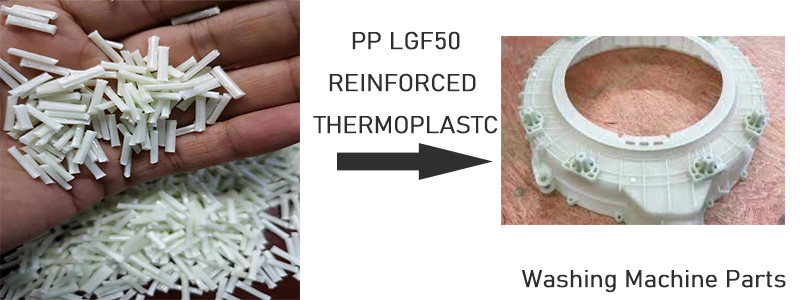

PP has good molding fluidity, but the shrinkage range and shrinkage value are large, and shrinkage holes, dents, and deformation are easy to occur. The cooling speed is fast, the pouring system and the cooling system should slowly dissipate heat

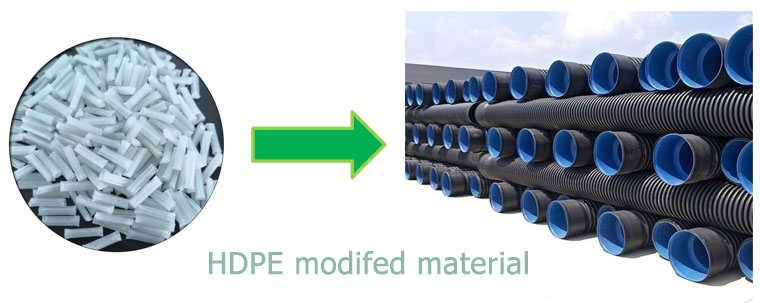

Polyethylene is divided into high-density polyethylene, low-density polyethylene, etc. LFT-G company specializes in the production of HDPE and long glass fiber composite materials, the density is between 1.10-1.40g/cm³, the density of different fiber content is not the same. The melt temperature is 210-250℃ the same as PP LGF. The PE resin material is easy to hydrolyze, and the long glass fiber is added to delay the hydrolysis. Although the water absorption is not high, it needs to be dried before processing to prevent the internal hydrolysis of the molecules during the processing from affecting the material properties.

One of the characteristics of nylon types is that they absorb water, so they must be dried before processing. It can be dried at 100-120℃ for about 4-6 hours. Allowable water content during molding: 0.1% for PA6 and PA66. Nylon is easy to cause discoloration during heating, so avoid high temperature. PA Long Glass Fiber Thermoplastic material is a thermoplastic material that can be processed twice. As a secondary material, try to avoid too many repeated uses to avoid a sharp decline in performance.