-

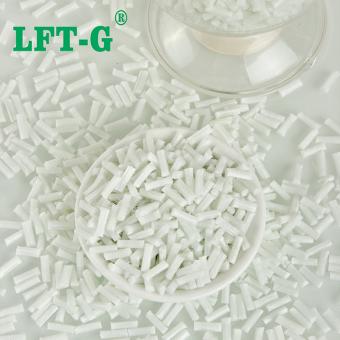

nylon 6 glass fiber granules V0 flame retardant recycle pa6 pelletsnylon 6 glass fiber granules V0 flame retardant recycle pa6 pellets good for toughness,anticreep,fatigue and low warpage.

- polyamide 6 engineering plastics

- PA6 resin

- nylon 6 glass fiber granules

- pa6 plastic raw materials prices nylon pa 6 lgf30 pa6 plastic raw material price pa6 30 gf material properties

- PA6 Pellets enginerring grade

- pa6 gf30 plastic pellets price

Tags :

-

PLA lgf20 pellets recycle virgin pla resin filled long glass fiber20pla recycle polymer are become more popular around the plastic market.

- PLA long glass fiber

- PLA reinforced thermoplastic

- PLA Glass fiber reinforced

- PLA LGF30 thermoplastic granules

- PLA granules fiber reinforced pp

- PLA gf30 pellets

Tags :

-

high toughness ppa thermoplastic long glass fiber reinforcedhigh toughness ppa thermoplastic long glass fiber reinforced which one is made in ourself factory.The production is very cheap and the quality is very high.

- ppa plastics granules

- high temperature resistant ppa

- ppa gf30

- ppa long fiber granules compolymer

- ppa granules lgf30

Tags :

-

Application of glass fiber modified PP LGF30 in automobile interior decorationPP Long Glass Fiber 30% Reinforced Thermoplastic Granules For Injection Mold

- LFT PP LGF GF30 composite

- Polypropylene GF30 Granules

- LFT reinforced thermoplastic granules

- PP LGF30 plastic

- Polypropylene long fiber composite

- Polymer reinforced composite

Tags :

-

LFT PA6 LGF20 Nylon 6 Enhance Modified Pellets For Plastic Injection GradeLFT Thermoplastic Enhance PA6 Long Glass Fiber 30% Pellets Lenght About 12mm

- PA6 LGF30 Enhance Modified Pellets

- PA6 Long Glass Fiber 30%

- High Structural Leval Of PA6 GF30

- Engineering plastic PA6 LGF30

- Nylon 6 GF30

- Polyamide 6 Modified Pellets

Tags :

-

LFT Homopolymer PP Long Glass Fiber 30% Polypropylene MaterialsProduct Name:Homopolymer LGF30, Polypropylene LGF30, Polypropylene Long Fiber Thermoplastic Form: Length about 12mm, High strength, High toughness Advantage: More than 20 years experience product in fiber reinforced plastic .

- PP LGF30

- PP GF30

- LFT PP LGF

- Homopolymer PP Glass Fiber 20%

- Polypropylene Long Fiber Thermoplastic

- Polypropylene LGF30

Tags :

-

LFT HDPE Long Glass Fiber 30% High Tensile Strength PE LGF30Product Name:HDPE LGF30, High Density Polyethylene Long Glass Fiber Reinforced Plastic Form: Length about 12mm, High Performance LFT Granules Advantage: Contact customer service to obtain TDS, or direct access to the website

- HDPE LGF30

- LFT HDPE

- High Density Polyethylene LGF30

- HDPE Long Glass fiber Reinforced Thermoplastic

- High Tensile Strength HDPE GF30

- HDPE Fill Glass Fiber Reinforced Plasitc

Tags :

-

LFT Polyamide Nylon 12 Long Glass Fiber 30% Composite For BicycleProduct Name: Polyamide12 long glass fiber 40% composite,Nylon Long fiber thermoplastic Certificated: SGS, 16949 system certificated,MSDS,and so on.

- LFT PA12 LGF 30

- Nylon Composite Materials

- Nylon 12 Plastic Composite

- Nylon12 Composite

- Nylon 12 LGF30

- Polyamide12 with fiber glass

Tags :

-

LFT reinforced plastic PA12 filling Long Glass Fiber original white color for sports parts and solar energyPA12 Nylon 12 is the least dense of the nylon series at 1.02. Its characteristics include low water absorption, good dimensional stability, good low temperature resistance, up to -70℃; Low melting point, easy forming processing, forming temperature range is wide; Soft, chemical stability, oil resistance, wear resistance are good, and is a self-extinguishing material. The long-term use temperature is 80℃ (up to 90℃ after heat treatment), can work at 100℃ for a long time in oil, inert gas can work at 110℃ for a long time. Long Glass Fiber Long fiber reinforced thermoplastics (fibrereinforced thermoplastics), referred to as LFT, refers to glass fiber reinforced composite materials (LFT) with a length of more than 5mm, has good molding processing properties, can be molded by injection, molding, extrusion and other processes, When forming, the plastic has good molding fluidity, and can be formed under low pressure. It can be formed into products with complex shapes, and the apparent mass of products is better than GMT. TDS for reference only Application Packing Industry introduction LFT & LFRT, long fiber reinforced thermoplastic engineering plastics, compared to conventional short fiber reinforced thermoplastics, typically have a fiber length of less than 1 to 2 mm in conventional short fiber reinforced thermoplastics, while the LFT process the thermoplastic engineering plastics produced have been able to maintain fiber lengths above 5 to 25 mm. The long fiber is impregnated with a special resin system to obtain a long strip which is sufficiently wetted by the resin, and then cut into a desired length as required. The most used matrix resin is PP, by PA6, PA66, PPA, PA12, MXD6, PBT, PET, TPU, PPS, LCP, PEEK and the like. Conventional fibers include glass fiber and carbon fiber. Special fibers include basalt fiber and quartz fiber. The LFT of the long fiber material can achieve better mechanical properties. According to the final different applications, the finished product can be used for injection molding, extrusion and molding, Etc., directly used to replace steel and thermoset products.

- long glass fiber polyamide12

- long fibre reinforced thermoplastics

- glass fiber reinforced plastics granules

- pa12 lgf30

- polyamide 12 lgf30

- lft pa6 modified

Tags :

-

LFT-G modified material ABS compounds Long Glass Fiber 20-60 injection molding for automotive partsABS material Acrylonitrile-butadiene styrene (ABS) resin is an opaque amorphous thermoplastic engineering plastic with complex two-phase structure. It is composed of styrene, acrylonitrile and butadiene in different proportions. In the 1970s, it began to be recognized by the public and began to be used. In the 1990s, the market demand grew rapidly. At present, it should be used in domestic and foreign markets, especially in construction, home appliances, automobiles and other industries. ABS-LGF Long glass fiber is widely used in engineering plastics. Reinforced ABS composites are made by adding a certain percentage of glass fiber, with the addition of 30% to 50% glass fiber being the most common. So as to improve the mechanical properties of ABS. Such as tensile properties, bending properties, and the corresponding molding shrinkage rate is not reduced, so that the material will not stress cracking. Advantages: 1. Long glass fiber reinforced, glass fiber is a high temperature resistant material, therefore, the heat resistant temperature of reinforced plastic is much higher than before without glass fiber, especially nylon plastics 2. After long glass fiber reinforcement, due to the addition of long glass fiber, the mutual movement between polymer chains of plastic is limited, therefore, the shrinkage rate of reinforced plastics decreases a lot, and the rigidity is greatly improved. 3. After long glass fiber reinforcement, reinforced plastics will not stress crack, at the same time, the anti-impact performance of plastics is improved a lot. 4. After long glass fiber reinforcement, glass fiber is a high strength material, which also greatly improves the strength of plastic, such as: tensile strength, compression strength, bending strength, improve a lot. 5. Long glass fiber reinforced after, due to the addition of glass fiber and other additives, the combustion performance of reinforced plastics decreased a lot, most of the material can not ignite, is a kind of flame retardant material. Datasheet for reference only Processing flow Cases About Xiamen LFT-G Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series(LGF) & Long Carbon Fiber Series(LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 system certification, and the products have obtained lots of national trademarks and patents.

- Modified material lft

- ABS compounds long glass fiber

- lgf injection mold abs

- reinforced material abs filling lgf

- ABS-LGF30

- Thermoplastic resin ABS

Tags :

-

Xiamen LFT MXD6 filling Long glass fiber30 high toughness good price injection moldingMXD6 Polyadipyl-m-benzoylamine, abbreviated as mxd6, resin has higher mechanical strength and modulus than other engineering plastics, is also a special high barrier nylon material. Although the barrier of mxd6 is slightly worse than that of pvdc and evoh, its barrier is not affected by temperature and humidity, which is especially suitable for high temperature and humid occasions. In today's barrier packaging and plastic instead of steel general trend, nylon mxd6 has become one of the most eye-catching new plastic varieties. Structure performance: MXD6 nylon material has high strength, high rigidity, high thermal deformation temperature, small thermal expansion coefficient; Dimensional stability, low water absorption rate and small size change after water absorption, mechanical strength changes less; Forming shrinkage is small, suitable for precision forming processing; Excellent coating performance, especially suitable for high temperature surface coating; Excellent barrier to oxygen, carbon dioxide and other gases. Excellent mechanical and thermal properties and high strength, high modulus and heat resistance, high barrier, excellent cooking resistance. MXD6-LGF MXD6 can be compounded with glass fiber for use in fiberglass reinforced materials containing 50-60% glass fiber for exceptional strength and stiffness. Even when filled with high glass content, its smooth, resin-rich surface produces a fibre-free high gloss surface, ideal for painting, metal-plating, or creating naturally reflective shells. 1, suitable for high liquidity of thin wall It is a very fluid resin that can easily fill thin walls as thin as 0.5 mm thick even when the glass fiber content is as high as 60%. 2. Excellent surface finish A resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content. 3. High strength and stiffness The tensile and flexural strength of MXD6 is similar to that of many cast metals and alloys with the addition of 50-60% glass fiber reinforced material. 4, good dimensional stability At ambient temperatures, the linear expansion coefficient (CLTE) of MXD6 glass fiber composites is similar to that of many cast metals and alloys. Strong reproducibility due to low shrinkage and the ability to maintain tight tolerances (length tolerances as low as ± 0.05% if properly formed). MXD6 replaces metal to produce high-quality structural parts for automobiles, electronics and electrical appliances In automobile parts, many occasions require material products with high mechanical strength and good oil resistance, and can be used in the range of 120 ~ 160℃ for a long time. Glass fiber reinforced MXD6 heat resistant temperature up to 225℃, high rate of strength retention at high temperature, can be used in the cylinder block, cylinder head, piston, synchronous gear, etc. MXD6/PPO alloy has high temperature resistance, high strength, oil resistance, wear resistance, good dimensional stability and other properties, can be used for the vertical outer plate of the automobile body, front and rear fenders, wheel covers and almost can not use steel plate stamping forming curved parts and automobile chassis. Datasheet for reference Application fileds Production process Xiamen LFT composite plastic Co., Ltd Q. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. Q. Under what circumstances can long fiber replace short fiber? What are the common alternative materials? A. Traditional staple fiber materials can be replaced with long glass fiber and long carbon fiber LFT materials in the case of customers whose mechanical properties cannot be met or where higher metal substitutes are desired. For example, PP long glass fiber is often replacing nylon reinforced glass fiber, and nylon long glass fiber is replacing PPS series. Q. Does long glass fiber and long carbon fiber injection have special requirements for injection molding machines and molds? A. There are certainly requirements. Especially from the product design structure, as well as the injection molding machine screw nozzle and mold structure injection molding process must consider the requirements of long fiber.

- polyadipyl-m-benzoylamine LGF

- MXD6 long fiber glass composite

- Modified MXD6 lgf

- MXD6 compounds long glass fiber

- MXD6-NA-LGF30

- lft-g MXD6 fiber filled

Tags :

-

lft-g PA66 reinforced material long glass fiber 30% specification Polyamide66 modified plasticWhat is PA66? PA66, abbreviation of Polyamide 66, chemical name polyadiptyl adiptyl diamine, commonly known as nylon 66. Is a colorless transparent semi-crystalline thermoplastic polymer, widely used in automobiles, electronic appliances, mechanical instruments, industrial parts and other industries. What is PA66-LGF? However, due to the large absorbency of nylon itself, poor acid resistance, low impact strength of dry state and low temperature, and easy deformation after water absorption, the dimensional stability of the product is affected, so that its application range is limited to some extent. In order to improve the above shortcomings, expand its application field, and better meet the requirements of performance, people adopt a variety of methods to modify PA66 plastic, so as to improve the impact property, thermal deformation property, forming processing property and chemical corrosion resistance. Because the specific strength and Young's modulus of glass fiber (LGF) are 10~20 times larger than that of PA66, the linear expansion coefficient is about 1/20 of that of PA66, the water absorption is close to zero, and it has good heat and chemical resistance, glass fiber filling is the most commonly used enhancement modification method of PA66. PA66 is the variety with the highest mechanical strength and the most widely used in PA series. Because of its high crystallinity, it has high rigidity and heat resistance. TDS Translucent or opaque opalescent crystalline polymer with plasticity. It has excellent wear resistance, self lubricity and high mechanical strength. Application 1. The automobile industry Because of its excellent heat resistance, chemical resistance, strength and convenient processing, nylon 66 has been widely used in the automobile industry. At present, it can be used in almost all parts of the automobile, such as the engine parts, electrical parts and body parts. The engine part includes the intake system and the fuel system, such as the engine cylinder head cover, throttle, air filter machine housing, vehicle air horn, vehicle air conditioning hose, cooling fan and its housing, water inlet pipe, brake oil tank and cover, and so on. Body parts include: car fender, rear view mirror frame, bumper, dashboard, luggage rack, door handle, wiper bracket, seat belt buckle, interior decoration and so on. Car electric appliances such as electric control doors and Windows, connectors, crisper, cable tie wire. 2. Electronic and Electrical industries PA66 can produce electronic and electrical insulation parts, precision electronic instrument parts, electrical lighting appliances and electronic and electrical parts, can be used to make rice cookers, electric vacuum cleaners, high-frequency electronic food heaters, etc. PA66 has excellent solder resistance and is widely used in the production of junction boxes, switches and resistors. Flame retardant grade PA66 can be used for color TV wire clip, fixing clip and focusing knob. 3. Machinery transportation and machinery and equipment industry PA66 can be used for door handles of passenger cars and brake joint discs of freight cars. Other products such as insulation washer, baffle seat, turbine, propeller shaft, screw propeller and sliding bearing on ship can also be made with PA66. High impact resistance nylon 66 can also be made pipe pliers, plastic molds, radio control body, etc. Unreinforced grade nylon 66 is usually used to manufacture nuts, bolts, screws, nozzles, etc. with low creep and no corrosion. Reinforced grade nylon 66 used in the production of chains, conveyor belts, fan blades, impeller and scaffolding fixed foot buckle. Details Number Color Length MOQ Package Sample Delivery time Port of Loading PA66-NA-LGF30 Original color 12mm 25kg 25kg/bag Available 7-15 days after shipment Xiamen Port Frequently asked questions 1. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 2. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the product, it needs to be evaluated in combination with specific products. 3. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A. The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

- Polyamide 66 lgf filling lgf

- long glass fiber polyamide66

- pa66 lgf30

- long fiber compounds pa66

- polyamide 6.6 lgf30

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文