-

China Carbon Fiber Polyphenylene Sulfide Modified CompoundsPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- plastic granules price per kg

- long fibre reinforced thermoplastics

- PPS Plastic

- pps melting point

- Injection molding pps

- Engineering plastic

Tags :

-

China Carbon Fiber Polyphenylene Sulfide Modified CompoundsPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.view more

-

MXD6 filling Long glass fiber30 high toughness injection molding natural color sample availableMXD6 Plastic | Long Glass Fiber Reinforced MXD6 (MXD6-LGF) What is MXD6? Polyadipyl-m-benzoylamine, commonly referred to as MXD6 or nylon MXD6, is a high-performance engineering thermoplastic. Compared to other engineering plastics, MXD6 has higher mechanical strength and modulus. It is also a special high barrier nylon, with excellent resistance to oxygen and carbon dioxide. Unlike PVDC or EVOH, its barrier performance is not affected by temperature or humidity, making MXD6 ideal for high-temperature and humid conditions. Structural and Mechanical Performance MXD6 nylon exhibits high strength, high rigidity, high thermal deformation temperature, low thermal expansion, excellent dimensional stability, and low water absorption. Its mechanical properties change minimally after water absorption. MXD6 has low shrinkage for precision forming, excellent paintability at high temperatures, and outstanding barrier properties. Advantages of MXD6 Maintains high strength and rigidity over a wide temperature range High heat deflection temperature with low thermal expansion coefficient Low water absorption and minimal mechanical property reduction Small molding shrinkage, suitable for precision molding processes Excellent paintability, especially at high temperatures Outstanding barrier to oxygen, carbon dioxide, and other gases MXD6-LGF | Long Glass Fiber Reinforced MXD6 MXD6 can be compounded with long glass fibers, carbon fibers, minerals, and advanced fillers to produce composites with 50-60% glass fiber reinforcement. This results in exceptional strength and stiffness while maintaining a smooth, resin-rich surface ideal for painting, metal coating, or reflective housings. Key Advantages of MXD6-LGF High fluidity for thin walls: Can fill walls as thin as 0.5 mm even with 60% glass fiber content. Excellent surface finish: Resin-rich surfaces provide high gloss appearance despite high fiber content. Very high strength and stiffness: Comparable to many cast metals and alloys with 50-60% glass fiber. Good dimensional stability: Low shrinkage and tight tolerances; coefficient of linear expansion similar to many metals. MXD6-LGF TDS (Technical Data Sheet) Applications of MXD6-LGF MXD6-LGF replaces metals for high-quality structural parts in automotive, electronics, and electrical appliances. It performs well in environments requiring high mechanical strength and oil resistance, operating at 120–160℃ long-term. With glass fiber reinforcement, MXD6 maintains heat resistance up to 225℃, suitable for cylinder blocks, cylinder heads, pistons, and synchronous gears of automotive engines. MXD6/PPO alloys offer high temperature resistance, high strength, wear resistance, oil resistance, and excellent dimensional stability, enabling metal replacement in automotive body panels, fenders, wheel covers, and complex curved parts. About Us

- long glass fiber MXD6

- long glass fiber reinforced plastics granules

- MXD6 LGF

- glass fiber reinforced plastics granules

- MXD6 compounds

Tags :

-

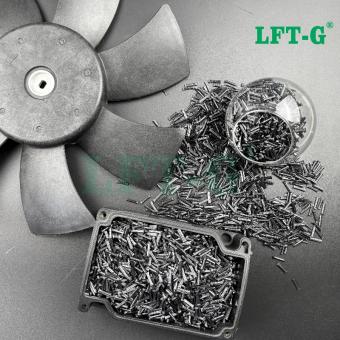

LFT-G Polyamide 12 long carbon fiber reinforced compounds nylon for car partsLong Carbon Fiber Carbon fiber exhibits outstanding properties, including extremely high axial strength and modulus, low density, and excellent specific performance. It shows no creep, outstanding fatigue resistance, excellent corrosion resistance, and maintains stability at very high temperatures in non-oxidizing environments. Carbon fiber also features good electrical and thermal conductivity, effective electromagnetic shielding, a low coefficient of thermal expansion, and strong anisotropy. Compared with traditional glass fiber, carbon fiber offers more than three times the Young’s modulus and approximately twice the modulus of aramid (Kevlar) fiber. It is insoluble and does not swell in organic solvents, acids, or alkalis, making it highly suitable for corrosive and demanding environments. One effective way to reduce the cost of carbon fiber applications is to combine it with engineering plastics such as nylon, creating high-performance composite materials with optimized cost-performance balance. As a result, carbon fiber reinforced nylon has become an important material system in modern composite engineering. Nylon itself is a high-performance engineering plastic, but it suffers from moisture absorption, limited dimensional stability, and mechanical properties far below those of metals. To overcome these limitations, fiber reinforcement has been applied since the 1970s. Carbon fiber reinforced nylon significantly improves strength, stiffness, thermal stability, creep resistance, wear resistance, and dimensional accuracy. Compared with glass fiber reinforced nylon, carbon fiber reinforced nylon offers superior damping behavior and overall mechanical performance. Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. In particular, for additive manufacturing, SLS (Selective Laser Sintering) technology is considered one of the most suitable methods for processing carbon fiber reinforced nylon materials. TDS for Reference Applications Our Company Xiamen LFT Composite Plastic Co., Ltd. is a professional manufacturer specializing in Long Fiber Reinforced Thermoplastics (LFT & LFRT), including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our LFT materials are suitable for LFT-G injection molding, extrusion processes, and LFT-D compression molding. Fiber length can be customized from 5 to 25 mm according to customer requirements. Our continuous fiber impregnation technology has passed ISO 9001 and IATF 16949 certification, and our products are protected by multiple trademarks and patents.

- carbon fiber reinforced plastics granules

- long carbon fiber reinforced pa12

- long fiber composite pa6 granules

- pa6 lcf polymers carbon fiber CFRP good price polymer

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文