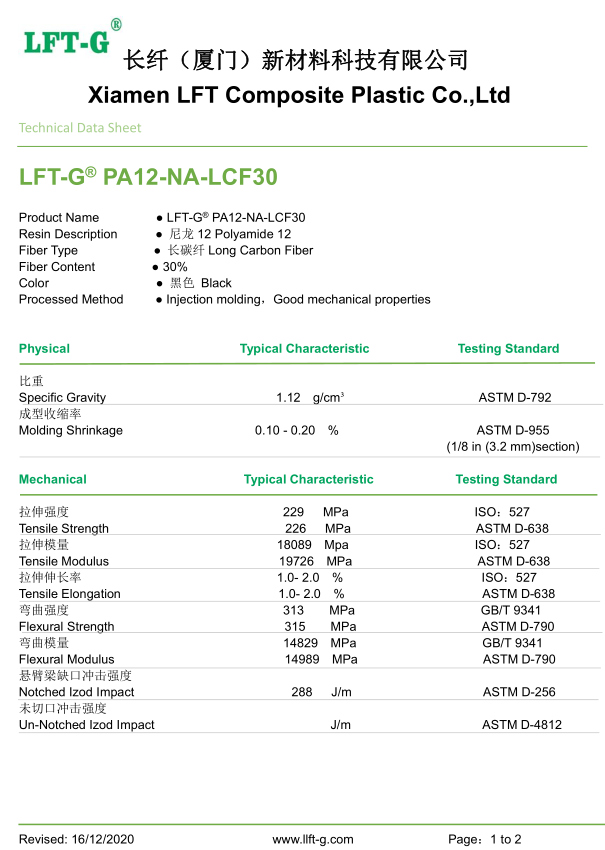

item no.:

PA12-NA-LCF30Payment:

T/T or L/C (other payment ways also can be diproduct origin:

Xiamen, ChinaColor:

Original color (also can be customized)shipping port:

Xiamen, ChinaCarbon fiber exhibits outstanding properties, including extremely high axial strength and modulus, low density, and excellent specific performance. It shows no creep, outstanding fatigue resistance, excellent corrosion resistance, and maintains stability at very high temperatures in non-oxidizing environments. Carbon fiber also features good electrical and thermal conductivity, effective electromagnetic shielding, a low coefficient of thermal expansion, and strong anisotropy.

Compared with traditional glass fiber, carbon fiber offers more than three times the Young’s modulus and approximately twice the modulus of aramid (Kevlar) fiber. It is insoluble and does not swell in organic solvents, acids, or alkalis, making it highly suitable for corrosive and demanding environments.

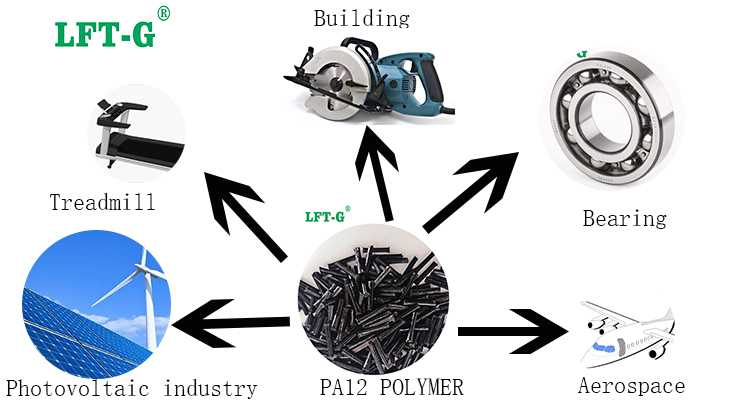

One effective way to reduce the cost of carbon fiber applications is to combine it with engineering plastics such as nylon, creating high-performance composite materials with optimized cost-performance balance. As a result, carbon fiber reinforced nylon has become an important material system in modern composite engineering.

Nylon itself is a high-performance engineering plastic, but it suffers from moisture absorption, limited dimensional stability, and mechanical properties far below those of metals. To overcome these limitations, fiber reinforcement has been applied since the 1970s. Carbon fiber reinforced nylon significantly improves strength, stiffness, thermal stability, creep resistance, wear resistance, and dimensional accuracy. Compared with glass fiber reinforced nylon, carbon fiber reinforced nylon offers superior damping behavior and overall mechanical performance.

Therefore, carbon fiber reinforced nylon (CF/PA) composites have developed rapidly in recent years. In particular, for additive manufacturing, SLS (Selective Laser Sintering) technology is considered one of the most suitable methods for processing carbon fiber reinforced nylon materials.

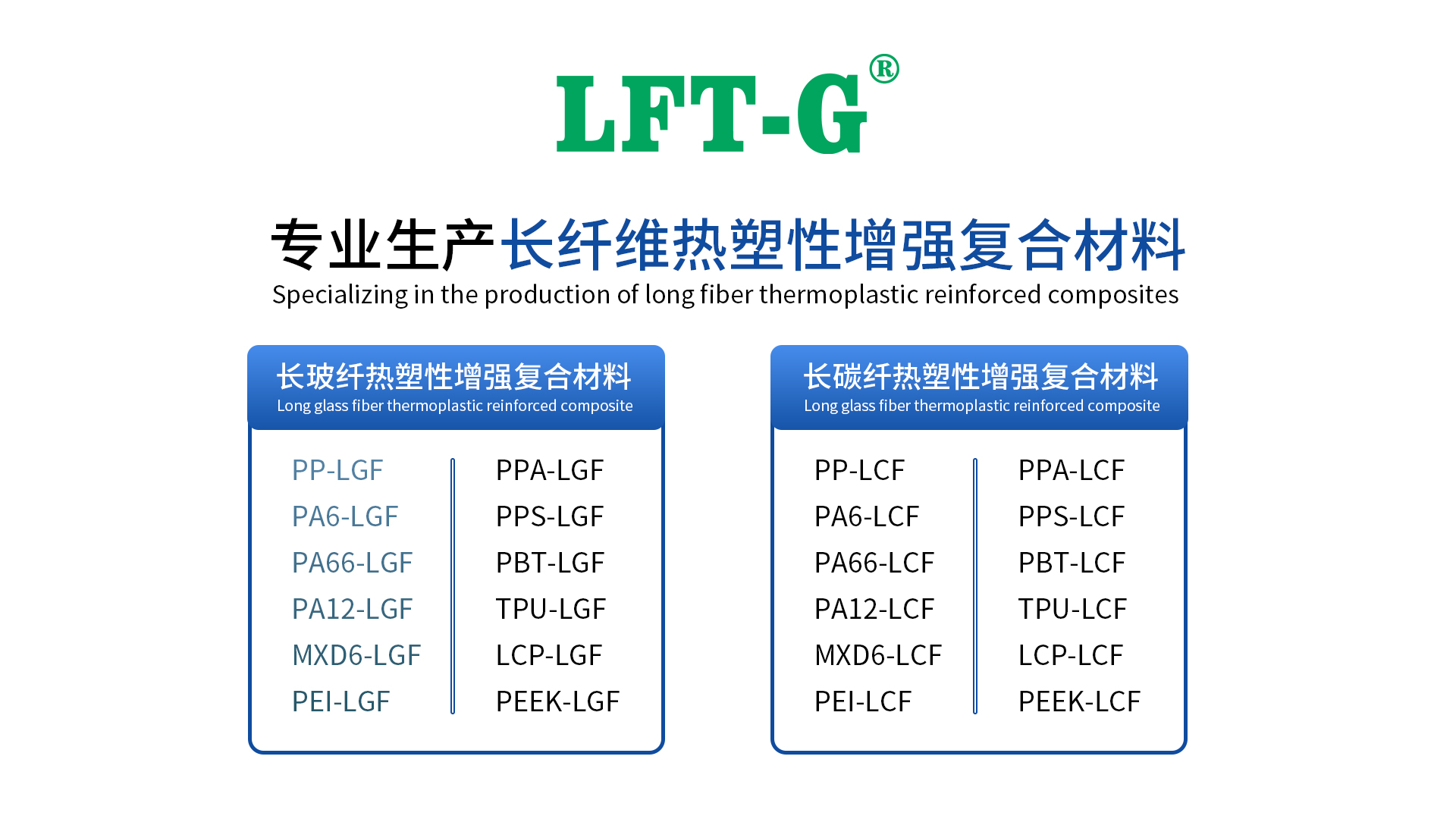

Xiamen LFT Composite Plastic Co., Ltd. is a professional manufacturer specializing in Long Fiber Reinforced Thermoplastics (LFT & LFRT), including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series.

Our LFT materials are suitable for LFT-G injection molding, extrusion processes, and LFT-D compression molding. Fiber length can be customized from 5 to 25 mm according to customer requirements. Our continuous fiber impregnation technology has passed ISO 9001 and IATF 16949 certification, and our products are protected by multiple trademarks and patents.