-

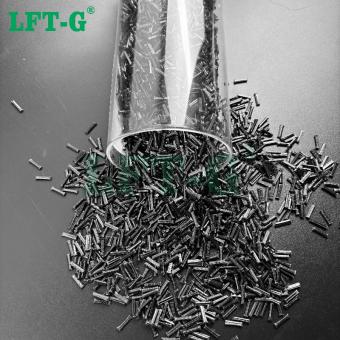

High Temperature Resistant PPS Long Glass Fiber Polymer PelletsPPS lengthened glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, and good product appearance. It can be used in water heater impellers, pump casings, joints, valves, chemical pump impellers and casings, cooling water impellers and Shells, home appliance parts, etc.

- PPS engineering plastic supplier

- Automotive PPS plastic parts

- PPS for industrial structural components

- long fiber thermoplastic

- PPS glass fiber reinforced material

- LFT granules

Tags :

-

PPS Engineering Plastic Resin Carbon Fiber Reinforced CompoundsPolyphenylenesulfide, is a thermoplastic special engineering plastic with excellent comprehensive properties. Its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties. The product will make a metallic sound when it is dropped to the ground.view more

-

PEEK Special Engineering Plastic Resin Carbon Fiber Reinforced CompoundsIt is highly resistant to chemicals and heat and capable of resisting submersion in liquids long-term. It also can generally be subjected to harsh operational environments. The mechanical properties of PEEK allow it to be used as reinforcement material in various scenarios.view more

-

Long Glass Fiber Reinforced Composites PPS SeriesPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- LFT-G

- High-strength PPS thermoplastic

- High-temperature resistant thermoplastics

- Aerospace-grade PPS composites

Tags :

-

Advanced Carbon Materials Polyphenylene Sulfide PelletsPPS long carbon fiber reinforced material features outstanding thermal stability, exceptional chemical resistance, and excellent mechanical strength, making it ideal for high-performance engineering applications. With superior stiffness, low moisture absorption, and inherent flame retardancy, this material is widely used in automotive, aerospace, and electrical industries. Its high strength and dimensional stability ensure reliable performance even in extreme environments.

- China manufacturer carbon fiber compounds

- PPS raw materials

- PA12 black carbon

- pps resin suppliers

- pps plastic melting point

- pps-cf

Tags :

-

LFT Polyphenylene Sulfide PPS Manufacturer Glass Fiber filled Compounds engineeing use

- PPS thermoplastic resinforced material

- fiber filling polymer instead of metal steel

- Sample free natural plastic new GFRP

- engineering plastic structural parts

- modified resin good price low MOQ

- Car parts application bearings

Tags :

-

PPS Pellets Carbon FiberPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats.

- polyphenylene sulfide plastic

- pps polyphenylene sulfide

- polyphenylene sulfide properties

- automotive carbon fiber

- plastic carbon fiber

- plastic pps

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文