-

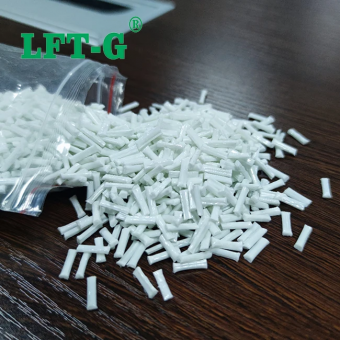

LFT Long Glass Fiber Reinforced PPA Compounds Special NylonPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- PPA Materials for Aerospace Applications

- PPA Composites for Automotive Parts

- OEM PPA Composite Materials

- PPA for Electrical Components and Devices

- PPA Reinforced Plastic for Structural Applications

- PPA Reinforced Thermoplastic

Tags :

-

LFT Long Glass Fiber Reinforced PLA Compounds Injection MoldingPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- wholesale glass fiber reinforced plastic resin dispenser in china

- pla price per kg

- thermoplastic resin suppliers

- reinforced pla

- polylactic acid (pla) plastic

- pla pellets

Tags :

-

New Materials LGF PPS Glass Fiber High Toughness Engineering UseThis product uses high-performance Polyphenylene Sulfide (PPS) resin combined with long glass fiber (LGF) reinforcement, modified with patented toughening technology. It offers outstanding mechanical properties, high temperature resistance, and dimensional stability. It is widely used in industries such as automotive, electronics, and machinery, particularly for high-strength, high-temperature, and impact-resistant structural parts.

- glass fiber reinforced plastic

- glass fiber reinforcement filler

- glass toughening plant

- PPS GF

- good composites for injection molding

- pps lft

Tags :

-

High-Strength PBT Composite for Advanced Structural ApplicationsOur PBT Long Glass Fiber Reinforced Structural Composite Material combines high-performance Polybutylene Terephthalate (PBT) resin with long glass fiber (LGF) to create a material that delivers exceptional strength, heat resistance, and dimensional stability. This advanced material is designed for demanding applications in industries such as automotive, electronics, and industrial machinery.view more

-

High Strength Polypropylene Carbon Fiber Filled Thermoplastic PelletsThrough carbon fiber reinforcement, can improve the strength of polypropylene materials, thermal deformation temperature and dimensional stability, expand the application of polypropylene materials.

- carbon fiber composites

- difference between copolymer and homopolymer

- long carbon fiber reinforced polypropylene manufacturers

- carbon fiber reinforced plastics

- what is homopolymer

- lft g for automobile market

Tags :

-

High Toughness Copo Polypropylene Carbon Fiber Filled Thermoplastic PelletsCombining the flexibility of Polypropylene and the properties of carbon fiber, PP-CF Compound material increases performance and brings reliability to the market.

- metal replacement solutions

- long fiber composites

- types of fibers in composite materials

- carbon reinforced plastic

- copolymer vs homopolymer polypropylene

- pp cf30

Tags :

-

Reinforced Nylon 1,2 Long Carbon Fiber Granules For High Demanding ApplicationsPa12 cf is a type of engineering plastic that consists of polyamide 12 (pa12) compounds reinforced with carbon fibers. It is a high-performance material that has many advantages over pure nylon 12, such as higher strength, stiffness, thermal resistance, chemical resistance, and electrical properties. Pa12 gf is widely used for various applications in different industries, such as automotive, aerospace, medical, electrical, and industrial.

- carbon fiber-reinforced plastic

- carbon fill pa plastic injection moulding supplier

- lightweight composite

- flammability properties

- nylon 66 cf30

- thermoplastic carbon fiber

Tags :

-

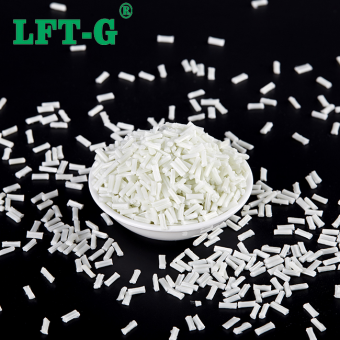

High rigidity and toughness Polyamide 12 filling long fiber compoundsPA12 PA12 polyamide or nylon 12 Chemical and physical properties of PA12 PA12 is a linear, semi-crystalline - crystalline thermoplastic material from butadiene. Its properties are similar to PA11, but its crystal structure is different. PA12 is a good electrical insulator and will not be affected by moisture as other polyamides. PA12 has good impact resistance mechanical and chemical stability. There are many improved varieties of PA12 in terms of plasticizing and reinforcing properties. Compared with PA6 and PA66, these materials have lower melting point and density, and have very high moisture recovery. PA12 has no resistance to strong oxidizing acids. The viscosity of PA12 depends mainly on humidity, temperature and storage time. PA12 It's very liquid. The shrinkage rate of PA12 is between 0.5% and 2%, depending on the variety of PA12 material, wall thickness and other process conditions. PA12 compounds plastic Nylon glass fiber material is a kind of composite material, adding glass fiber on the basis of the original nylon material, so that the material has the following characteristics: High temperature resistance, good dimensional stability, good toughness, good insulation, corrosion resistance, high mechanical strength. LGF & SGF comparison Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Datasheet for reference Application ■ Power tools: cutting machine, electric saw, electric drill, Angle grinder, polishing machine, electric hammer, electric pick, hot air gun and other models; ■ Automotive industry: cooling chamber, intake manifold, frame bracket, ventilation grille, door handle, throttle body and other models; ■ Machinery industry: water pump, water valve, bearing, shaft sleeve, gear, bracket and other models; ■ Sports equipment: ski equipment, baby carriage, fitness equipment parts and other models; ■ Office equipment: seat bracket, pulley, rotating shaft, shredder gear, printer parts and other models; Certification Factory Package Why choose us

- composite panels for ev batteries

- reinforced polyamide plastic

- nylon 12 application

- nylon pa12

- pa12 gf20

Tags :

-

Carbon Fiber PPS Plastic High Impact Resistance for EngineeringLFT long carbon fiber reinforced PPS material combines superior thermal stability and high mechanical strength, making it perfect for high-performance applications. Its excellent resistance to wear, chemicals, and high temperatures ensures long-lasting reliability in challenging environments.

- pps plastic

- carbon fiber reinforced plastic

- what is pps

- pps cf

- pps properties

- modified plastic

Tags :

-

High Performance PPS GF Glass Fiber Reinforced Thermoplastic PolymersPPS is a high-performance, tough engineering plastic with great dimensional and thermal stability, as well as a wide operating temperature range of up to 260 °C and good chemical resistance. Moreover, PPS, like most other thermoplastics, is an electrical insulator. Its ability to be used at high temperatures coupled with its thermal stability makes PPS great for applications such as semiconductor components in machinery, bearings, and valve seats. PPS-LGF compounds PPS plastic (polyphenylene sulfide), English name: Polyphenylenesulfide, is a thermoplastic special engineering plastic with excellent comprehensive properties. Its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties. The product will make a metallic sound when it is dropped to the ground. . Pure PPS is rarely used alone due to its brittle performance. Most of the PPS used is its modified variety. Glass fiber reinforced PPS is one of them. PPS lengthened glass fiber (LGF) composite material has the advantages of high toughness, low warpage, fatigue resistance, and good product appearance. It can be used in water heater impellers, pump casings, joints, valves, chemical pump impellers and casings, cooling water impellers and Shells, home appliance parts, etc. Automotive industry Applications: Due to its excellent mechanical properties, thermoplastic carbon fiber is widely used in the automotive field of fuel system components, sensors, shell components. On the one hand, it is because of the high strength and stiffness of PPS-LCF, and the finished parts are not easy to damage. On the other hand, PPS-LCF also has a relatively low coefficient of thermal expansion to ensure the stability of the finished product. In addition, PPS-LCF also has very good corrosion and heat resistance, making the application life of the finished product longer. Industrial Applications: In the industrial field, it is mainly used in the parts of equipment, such as chemical processing equipment, air pumps, gaskets, valves, etc. In addition to the high strength of the PS-LCF, it is also because the parts made by the PS-LCF have very good self-lubricating properties, which is very important for mechanical parts. Therefore, compared with the traditional carbon fiber material products, the performance has been greatly improved. The wide range of applications of PPS-LCF include aerospace, automotive manufacturing, electronic equipment, chemical and medical fields. Basic Performance of PPS-LGF 1 Excellent overall performance. PPS resin is a crystalline polymer with high hardness. Its crystal content is about 65% and its density is 1.34g/cm^3. It has excellent mechanical properties. Its tensile strength and bending strength are better than those of PA, PC, PBT, etc. It has extremely high rigidity and creep resistance. The mechanical properties will better after adding glass fiber reinforcement. 2 Excellent heat resistance. Its melting point can reach 275~291℃, and its heat distortion temperature is 135℃. After glass fiber reinforcement, its heat distortion temperature can reach 260℃. In air, polyphenylene sulfide reaches the weakening temperature at about 400°C, and polyphenylene sulfide begins to decompose in air at 700°C. The long-term use temperature is 200~240℃, and the thermal stability of long-term continuous use is better than all current engineering plastics. 3 The dielectric strength is better. PPS has a symmetrical molecular structure, non-polarity, and low water absorption, so its electrical insulation is very good. Compared with other engineering plastics, its dielectric constant is small, and its arc resistance is equivalent to that of thermosetting plastics. It can be used in high temperature, high humidity, frequency conversion, etc. Under harsh conditions, PPS can still maintain excellent electrical insulation. 4 preservative. Because PPS has a high degree of crystallinity, it has excellent chemical resistance and is insoluble in any organic solvent below 200°C. In addition to strong oxidizing acids, it can withstand the erosion of various acids, alkalis, and salts. After being soaked in various chemicals for a long time, it still maintains high strength. Materials Details Number PPS-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermopl...

- Glass fiber reinforced plastic

- pps gf

- plastic pps

- pps supplier

- what is the difference between pps and ppa

- pps pellets

Tags :

-

China Carbon Fiber Polyetheretherketone Modified CompoundsPure PEEK itself is a special engineering plastic, with radiation resistance, self-lubrication, high temperature resistance, wear resistance, fatigue resistance and other characteristics. The performance of carbon fiber reinforced PEEK material has improved in many aspects compared with pure PEEK material.

- carbon reinforced peek

- Why is PEEK Plastic So Expensive

- PEEK in Robots

- PEEK composites

- china carbon fiber

Tags :

-

China Carbon Fiber PLA Modified CompoundsLong Fiber Reinforced PLA (LFR-PLA) is an engineering plastic that combines long glass fibers with polylactic acid (PLA) resin. PLA itself is an environmentally friendly thermoplastic, known for its biodegradability. However, it has limited mechanical properties, such as strength, toughness, and heat resistance.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文