Long fiber reinforced thermoplastics are an excellent option to consider for metal replacement at a fraction of the weight.

Long fiber reinforced thermoplastics are an excellent option to consider for metal replacement at a fraction of the weight.

item no.:

CPP-NA-LCFPayment:

Discussedproduct origin:

ChinaColor:

Natural color or Customizedshipping port:

XiamenLead Time:

2-10 working days

Profile

Product Name: Xiamen LFT Polypropylene PP Copolymer with Long Carbon Fiber Reinforcement Polymers

Fiber Content: Filled 20%-60% Long Carbon Fiber

Pellet Appearance: 6-25 mm length pellets

Package: 20kg/bag

Advantages:

1.High shear resistance.

2.High operating temperature.

3.High corrosion resistance.

4.High impact resistance.

5.High dimensional stability.

What is Polypropylene?

Polypropylene, also known as PP or polypropene, is a polyolefin or saturated polymer. It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

Which Is Better, Homopolymer or Copolymer?

It depends. Neither homopolymer nor copolymer is better than the other. It will depend on the application as to which is more desirable. Homopolymers are better suited to high-strength and high-hardness applications, whereas copolymers are suited for corrosion resistance and high operating temperatures. Although a raw homopolymer has better mechanical properties, copolymers have better mechanical properties when reinforced with fiber over fiber-reinforced homopolymer. This is because copolymers are better suited to adhering to fibers.

Why filled Long Carbon Fiber?

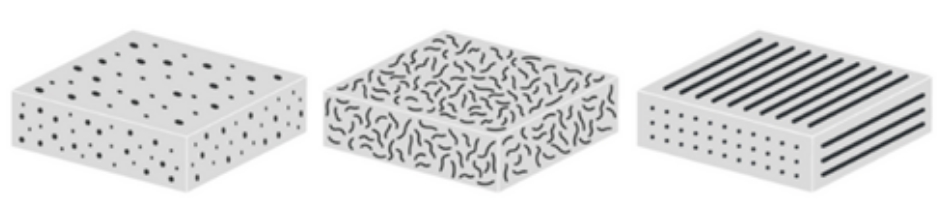

Long Carbon Fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long Carboin Fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymer. Long Fibers can be uniformly distributed inside the product to form a network skeleton, thus improving the mechanical properties of the material product.

The modified polypropylene material reinforced by carbon fiber has the characteristics of light weight, high modulus, high specific stiffness, low linear thermal expansion coefficient, and can be applied to many parts of automotive interior and exterior decoration. The carbon fiber reinforced modified polypropylene developed by Xiamen LFT meets the growing demand for lightweight new energy vehicles and will have a wider application space in the future.

(Contact us to get a showcase of successful cases )

What is the difference between long carbon fiber and short carbon fiber?

In order to improve the strength of glass fiber in plastics, the length of glass fiber must be greater than its critical length Lo. The relevant data show that when the fiber length is less than the critical length of the fiber reinforced plastics subjected to a certain load, the fiber will be pulled out, the fiber strength can not get full play. The critical length Lo is specific to the plastic variety. In the case of glass fiber reinforced polypropylene, the Lo is 3.1mm.

The results show that the failure mode is mainly the fiber is pulled out and cannot meet the strength requirement of the module carrier material. Therefore, the development and application of long glass fiber reinforced polypropylene and its injection molding technology, is to prepare the reinforced glass fiber length of about 10mm polypropylene raw materials, and through the improved injection molding process, ensure that the length of glass fiber in the product is more than 3.1mm.

Advantages of LFT compared with short fiber reinforced thermoplastic composites

The mechanical properties of the product are obviously improved by the longer fiber length.

High specific stiffness and strength, good impact resistance, especially suitable for automotive applications.

The creep resistance is improved, the dimensional stability is good, and the parts forming precision is high.

Excellent fatigue resistance.

Better stability in hot and humid environments.

The fiber can move relatively in the molding mold during the molding process, and the fiber damage is small.

Company profile

Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

Why buy polymers from Xiamen LFT?

Excellent quality. As replacement of metal and steel.

Own-factory. 500-800 tons of production per month.

Customization. From length to color or additives.

Self laboratory. Provide TDS and COA for every batch.

Fast shipping. Fast shipping to all capital cities or ports.

Favorable price. Free to get price.

Experienced team. With over 20 years experience expert team to provide assistance.

Full service. Through product discussion, performance analysis, composite selection, composite pellet production, after-sales tracking to injection molding techniques.