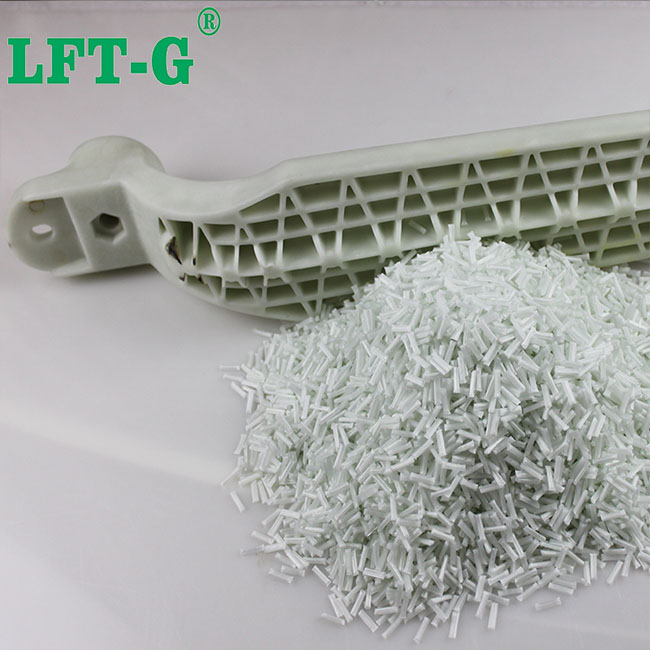

A new composite plastic hybrid solution has recently been developed for the production of robust and lightweight vehicle tool boxes. This application mixes a long glass fiber polypropylene resin and a continuous glass fiber composite laminate insert, produced using a two-shot injection molding process. Compared with steel parts of similar design, the finished parts produced by this solution are 30% lighter and effectively improve the production efficiency of the car. In addition to truck toolboxes, automotive applications for resin hybrid solutions include tailgates, seats, front-end modules, and battery housings for electric vehicles. Using this composite plastic solution can not only help manufacturers reduce body weight, but also reduce carbon emissions, control costs by increasing production efficiency, and improve vehicle performance. Laminate inserts are preheated before being placed into the mold and are two-shot injection molded with polypropylene resin in one operation. This insert increases stiffness and strength in critical areas of the part, enabling thin-wall geometries to reduce part weight. Compared to the steel traditionally used in truck toolboxes, this composite plastic hybrid solution offers a wider range of design options, enables integrated production of parts, and avoids secondary operations that can add cost and hinder mass production. Truck toolboxes produced with plastic composite solutions are approximately 30% lighter (4 - 6 kg) while maintaining the stiffness, toughness and strength required for the application.

view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文