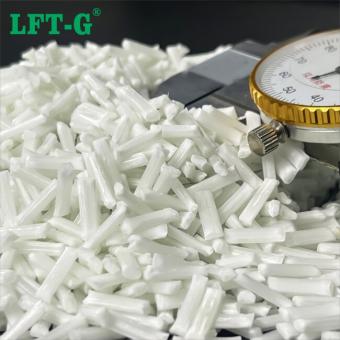

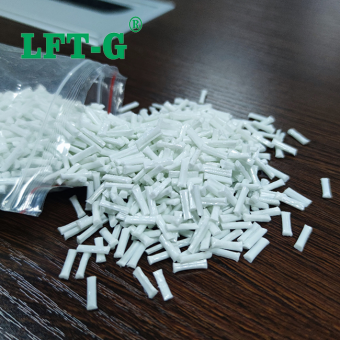

Long glass fiber has high strength, high rigidity, corrosion resistance, harsh environment suitability and low cost. When the resin matrix is impregnated and extruded into pellets ,Also called Long Glass Fiber Polymer it has good mechanical properties.

-

Xiamen LFT ABS (Acrylonitrile Butadiene Styrene) Long Glass Fiber Reinforced Thermoplastic CompoundsABS-LGF (Glass Fiber Reinforced ABS) Overview ABS is a versatile engineering plastic known for chemical and thermal stability, strength, toughness, and glossy finish. It is widely used in consumer products such as toys and helmets, as well as automotive applications like interior trim, housings for electronics, and more. Reinforcing ABS with glass fiber significantly improves rigidity, heat resistance, and dimensional stability. ABS-LGF composites provide excellent cost-performance balance, helping manufacturers reduce costs while meeting production needs. About ABS-LGF Compounds Applications of Modified ABS 1. Automotive Parts: Instrument panels, fenders, interiors, lights, mirrors, audio systems. 2. Electronic & Electrical Components: IT and OA equipment shells, converters, power sockets. 3. Electronic Appliances: Switches, controllers, monitors, housings, brackets. 4. Home Appliances: Electrical components, control boxes. Advantages of ABS Injection Molding High Productivity: Efficient, low-waste process ideal for high-volume manufacturing. Complex Part Design: Capable of multi-featured components, including overmolding and metal inserts. Increased Strength: ABS provides excellent mechanical strength and durability. Flexible Color & Material Options: Easily colored, painted, or electroplated to improve environmental resistance. Decreased Waste: Low-wastage production, limited to sprue, runners, and flashing. Low Labor Cost: Highly automated process reduces human intervention and lowers cost per part. Material Details Number ABS-NA-LGF Color Natural or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead Time 2-15 days Port of Loading Xiamen Port Trade Terms EXW / FOB / CFR / CIF / DDU / DDP About Xiamen LFT Founded in 2009, Xiamen LFT Composite Plastics Co., Ltd. is a leading global supplier of long fiber reinforced thermoplastic materials, integrating R&D, production, and marketing. Our products are ISO9001 & IATF16949 certified, patented, and applied in automotive, aerospace, medical, new energy, military, sports equipment, and more. Compared to short fiber thermoplastics (1-2 mm fibers), our LFT materials (5-25 mm fibers) are fully impregnated with resin, ensuring superior mechanical performance. Base resins include PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Conventional fibers include glass and carbon fibers. Finished products can be used for injection molding, extrusion, or directly replace steel and thermoset components.

- High performance thermoplastic engineering plastics

- excellent heat resistance with filler

- injection molding products light weight

- automotive parts house hold appliances

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

High strength PA12 nylon12 composite lgf virgin white color for automotiveProduct number: PA12-NA-LGF Fiber specification: 20%-60% Product feature: High strength, High toughness and durability Product application: Suitable for automotive, sports parts, solar energy, photovoltaic industry and other industries.

- Nylon12 filling long glass fiber reinforced plastic

- Durability high mechanical properties

- Photovoltaic industry compounds

- Injection grade thermoplastic resin

- 24h service customized plastic instead metal

- Supplier price good price pa6 composites

Tags :

-

Nylon series Polyamide 66 Long Glass Fiber Reinforced Thermoplastic ResinPolyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xiamen LFT offers a wide range of temperature-resistant nylons with many different filler materials. About PA66-LGF compounds Nylon 6,6, also written as nylon 6-6, nylon 66, or nylon 6/6, is a more crystalline version of nylon 6. It is also referred to as polyamide 66 or PA 66. It has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6. The advantages of nylon 6,6 are that the yield strength is higher than nylon 6 and nylon 610. It has high strength, toughness, rigidity, and low coefficient of friction in a wide temperature range. In addition, it is oil resistant and resistant to chemical reagents and solvents. However, PA66 has strong hygroscopicity and poor dimensional stability, which limits its application. In order to obtain nylon 66 engineering material with higher strength, it should be modified by glass fiber reinforcement. The mechanical properties of long glass fiber reinforced nylon 66 (LGFR-PA66) are obviously better than those of short glass fiber reinforced nylon 66 (SGFR-PA66), and the molding processing performance is also better. It can be molded by various molding methods such as injection molding and compression molding, and complex components can also be formed. Therefore, long glass fiber reinforced nylon 66 can be widely used in building materials, aerospace, electronic devices, furniture and other fields, especially in the automotive industry application market. The production process of long glass fiber reinforced nylon 66 is different from that of short glass fiber reinforced nylon 66. The short glass fiber reinforced nylon 66 particle is chopped under the friction and shearing of screw and barrel, and the short glass fiber reinforced nylon 66 particle is obtained with the length of glass fiber monofilament about 0.5mm. The length of some glass fiber monofilament in the final product is lower than the critical length of reinforcement, and the glass fiber is easy to be extracted from the nylon 66 matrix when the product is stressed. The strength of glass fiber is not fully utilized, and the mechanical properties of the product are not high. Long glass fiber reinforced nylon 66 has better reinforcement effect and dimensional stability, and the rigidity, tensile, bending, impact resistance and fatigue resistance of the manufactured products are better, and the service life is longer. Materials Details Number PA66-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.view more

-

Xiamen LFT-G Nylon 6 Polyamide 6 composite Long Glass Fiber modified plastic 12mm original colorPA6 Material Overview PA6 (Polyamide 6) is a widely used engineering plastic with excellent balanced performance. Its raw materials are readily available and cost-effective, making it accessible without dependence on foreign technology. However, PA6 has some limitations such as high water absorption, lower low-temperature impact toughness, and moderate dimensional stability. To overcome these limitations, PA6 is often reinforced with glass fiber (GF) to enhance mechanical properties. PA6-LGF (Long Glass Fiber Reinforced PA6) 1. Influence of Glass Fiber Content Glass fiber content is a key factor in the performance of reinforced composites. Increasing fiber content increases fiber density, thinning the PA6 matrix between fibers. This enhances impact toughness, tensile strength, and bending strength. Example: For PA6-LGF, increasing fiber content to 35% raised notch impact strength from 24.8 J/m to 128.5 J/m. However, excessive fiber content can reduce impact strength. Bending strength also improves as fibers transfer stress and absorb energy when broken, with experimental results showing bending modulus up to 4.99 GPa for 35% LGF. 2. Influence of Fiber Retention Length Fiber length significantly affects mechanical properties. When fiber length is below the critical length, increasing length improves resin-fiber bonding and tensile load resistance. When fiber exceeds the critical length, longer fibers absorb more impact energy and improve impact strength, as the number of fiber ends (crack initiation points) decreases. Example: At 40% fiber content, increasing fiber length from 4mm to 13mm improved tensile strength from 154.8 MPa to 164.4 MPa, with bending strength and notched impact strength increasing by 24% and 28%, respectively. Fibers longer than 7mm enhance warping resistance and mechanical stability under high temperature and humidity. Technical Data Reference (TDS) PA6-LGF can be reinforced with 20%-60% long glass fiber depending on product requirements. Compared to unreinforced PA6, PA6-LGF offers enhanced strength, heat resistance, impact resistance, dimensional stability, and reduced warping. The following TDS shows the data for PA6-LGF30. Applications of PA6-LGF PA6-LGF is widely used in automotive, electronic/electrical, and machinery/engineering parts. Automotive Parts Lightweight and miniaturization trends promote PA6-LGF use in engines, electrical systems, and body components. Electronic & Electrical Components Excellent flame retardancy and corrosion resistance make PA6-LGF suitable for switchgear, circuit breakers, contactors, connectors, and cable protection tubes. Mechanical & Engineering Parts Good impact resistance, wear resistance, and self-lubrication properties allow PA6-LGF to be used in machinery and engineering accessories. About Xiamen LFT Composite Plastics Co., Ltd. Xiamen LFT focuses on Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) reinforced thermoplastics. Our LFT materials support injection molding (LFT-G) and extrusion molding, as well as LFT-D molding, with fiber lengths from 5–25mm. Our products are ISO9001 & IATF16949 certified, patented, and widely used in automotive, electronics, industrial, and engineering applications.

- PA6 thermoplastic resin materials

- nylon 6 granules

- glass fiber reinforced plastics granules

- long fiber compounds pa6

- Injection molding plastic

- LFT-G reinforced material

Tags :

-

Xiamen LFT PP Polypropylene engineeing plastic long glass fiber composite granules 12mmWhat is Long Glass Fiber (LGF)? Long glass fiber reinforced plastics (LFT) are engineered materials in which long glass fibers and additives are incorporated into a base thermoplastic. This significantly improves mechanical strength, heat resistance, dimensional stability, and the overall performance of the material. Why Reinforce with Long Glass Fiber? High heat resistance: LFT significantly increases the thermal performance, especially for nylon-based plastics. Reduced shrinkage & higher rigidity: Fiber reinforcement restricts polymer chain movement, improving dimensional stability and stiffness. Improved impact resistance: Reinforced plastics are less prone to stress cracking and have better toughness. High strength: Long glass fibers increase tensile, compressive, and bending strength. Flame retardancy: Most LFT materials are self-extinguishing due to additives and fiber content. Why Choose Long Glass Fiber over Short Glass Fiber? Longer fiber length significantly enhances mechanical properties. High specific stiffness and strength with excellent impact resistance, ideal for automotive applications. Superior creep resistance and dimensional stability for precision parts. Excellent fatigue resistance for long-life components. Improved stability under hot and humid environments. Minimal fiber damage during molding due to relative fiber movement in the mold. Appearance of PP-LGF Applications of PP-LGF Automotive Parts Front end modules, door modules, shift mechanisms, electronic accelerator pedals, dashboards, cooling fans, battery carriers, bumper brackets, underbody protection plates, sunroof frames, etc. – replacing reinforced PA or metal components. Household Appliances Washing machine drums, brackets, air conditioning fans, etc. – replacing short glass fiber reinforced PA and metal components. Communications, Electronics, Electrical Appliances High-precision connectors, igniter components, coil shafts, relay bases, microwave transformer frames, solenoid valve housings, scanner components, etc. Other Applications Power tool housings, water pump/meter housings, impellers, bicycle frames, skis, locomotive pedals, safety helmets, safety shoes – replacing short fiber reinforced PA or PPO. Datasheet for Reference About Us Xiamen LFT Composite Plastics Co., Ltd. is a leading supplier of Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) reinforced thermoplastics. Our LFT materials support injection molding, extrusion molding, and are available in fiber lengths of 5–25mm, tailored to customer requirements. ISO9001 & IATF16949 certified, our products are patented and widely used in automotive, electronics, industrial, and defense applications. What We Offer Technical data and guidance for LFT & LFRT materials. Mold design recommendations for optimized production. Injection molding and extrusion support for consistent product quality.

- Polypropylene filling lgf GFRP 30

- thermopalstic Polymer virgin grade

- LFT-G car parts home appliance parts

- PP resin GF made in China modified plastic

- long fiber compounds pp instead metal and steel

- injection molding pp composite

Tags :

-

LFT High perofrmance Polypropylene with fiber LFT materials injection molding compoundPP glass fiber compound is a combination of PP resin, glass fiber and other specific additives PP glass fiber compound is made of PP base resin, glass fiber, and other additives. It gives the final products increased flexural modulus and tensile strength. With those high-performance properties, glass fiber-reinforced polypropylene delivers superior strength for furniture, electric appliances, and automobile applications.

- pp resin filament plastic metal replacement

- directly processed high tensile strength

- Improve stiffness reduce shrinkage

- Enhance impact strength and thermal resistance

- ISO FDA Certificate ROHS REACH

- car parts washing machine drum parts

Tags :

-

Xiamen LFT-G PLA Polylactic acid composite long glass fiber filling thermoplastic resin original colorPLA Plastic | Long Glass Fiber Reinforced PLA (PLA-LGF) What is PLA? Polylactic acid (PLA) is a biodegradable and eco-friendly polymer plastic, produced via pollution-free processes. PLA can naturally degrade and recycle in the environment, making it an ideal green polymer material and one of the most representative biodegradable plastics. PLA Structure and Heat Resistance The molecular structure of PLA affects its heat resistance, toughness, mechanical strength, degradability, and biocompatibility. PLA has a spiral molecular chain with low activity, resulting in slow crystallization after injection molding and relatively poor heat resistance. During hot processing, ester bonds may break partially, generating terminal carboxyl groups that accelerate thermal degradation. Long Glass Fiber (LGF) Reinforced PLA Reinforcing PLA with long glass fibers (PLA-LGF) improves mechanical strength, rigidity, and heat resistance. The fibers act as skeleton support, restricting polymer chain movement during heating and increasing thermal stability. Types of Fibers for PLA Reinforcement Fibers used for PLA enhancement include: Natural plant fibers: sisal, flax, linen, bamboo, coconut, wood fiber Animal fibers: silk Mineral fibers: basalt fiber Chemical fibers: glass fiber, carbon fiber Glass fiber and carbon fiber are widely used due to their high strength and modulus, while natural fibers are favored for biodegradability and renewable sources. Modified fibers blended with PLA have shown Vicat softening temperatures exceeding 140°C. Compared with Short Fiber (SGF) Long glass fiber reinforced PLA demonstrates superior mechanical properties compared with short fiber (SGF) reinforced PLA. It is more suitable for large structural parts, offering 1–3 times higher toughness and 0.5–1 times greater tensile strength and rigidity. Injection Molding of PLA-LGF Lab & Testing Warehouse & Storage Certification About Xiamen LFT Composite Plastic Co., Ltd. Xiamen LFT Composite Plastic Co., Ltd. specializes in long fiber reinforced thermoplastics (LFT) including PLA

- PLA composite plastic can be recycled

- polyactic acid materials injection molding

- modified pla compounds

- pla long glass fiber reinforced plastic resin

- long glass fiber filling pla sample available

- lft-g pla lgf low warpage

Tags :

-

LFT-G engineering plastic PBT filling long glass fiber 20%-60% reinforced materials high mechanical properties good pricePBT Plastic | Long Glass Fiber Reinforced PBT (PBT-LGF) What is PBT? Polybutylene terephthalate (PBT) is a semi-crystalline engineering thermoplastic polyester. It is produced via polycondensation of 1,4-butylene glycol and terephthalic acid (PTA) or dimethyl terephthalate (DMT), forming a milky white translucent to opaque resin. PBT exhibits excellent mechanical strength, chemical resistance, thermal stability, and electrical insulation properties, making it ideal for demanding engineering applications. Basic Properties of PBT Specific gravity: 1.31 g/cm³ Melting point: 225~275°C Glass transition temperature (Tg): 22–43°C Rockwell hardness (R scale): 118 Water absorption: 0.34% Molding shrinkage: 1.7~2.3% PBT-LGF | Long Glass Fiber Reinforced PBT PBT-LGF combines PBT with long glass fibers, improving mechanical strength, fatigue resistance, dimensional stability, and creep resistance. These properties are maintained even under high-temperature conditions. Advantages of PBT-LGF Excellent mechanical strength and fatigue resistance High heat resistance: UL temperature index 120–140°C Good solvent resistance and no stress cracking Easy flame-retardant processing: UL94 V-0 achievable Excellent electrical insulation: high resistivity, dielectric strength, arc resistance Good molding and secondary processing: injection molding and extrusion Fast crystallization and good fluidity: thin walls can be processed in seconds PBT-LGF Technical Data Sheet (TDS) Applications of PBT-LGF Long glass fiber reinforced PBT is widely used in electronics, automotive, and industrial applications due to its high mechanical strength, heat resistance, electrical insulation, and dimensional stability. Electronics: fuse-less wire breakers, electromagnetic switches, transformers, appliance handles, connectors, housings Automotive: door handles, bumpers, distributor covers, fenders, wire guard shells, wheel covers Industrial parts: OA fans, keyboards, fishing reels, lampshades, and other mechanical components Processing of PBT-LGF PBT-LGF can be easily processed via injection molding or extrusion using standard equipment. Due to fast crystallization and good fluidity, mold temperatures are lower than other engineering plastics, enabling rapid processing of both thin-walled and large parts. PBT-LGF Product Details Number Color Length Sample MOQ Package Port of Loading Delivery time PBT-NA-LGF30 Natural color (customizable) 12mm (customizable) Available 1 ton 25kg/bag Xiamen Port 7-15 days after shipment Lab & Factory Frequently Asked Questions Q: Does long glass fiber injection require special molding machines or molds? A: Yes. Injection molding machines, screws, nozzles, and mold structures must meet long fiber reinforcement requirements. Q: How to prevent rough surfaces or floating fibers in PBT-LGF injection molding? A: Ensure plastic particles are fully dried and plasticized, adjust mold temperature appropriately, and polish mold surfaces for smooth finishes.

- PBT pellets lgf 30 polymer

- LFT PBT modified plastic glass fiber

- reinforced PBT for car parts gfrp

- self owing pbt pellets

- best price PBT glass fiber compounds

- composite pbt-lgf sample free

Tags :

-

MXD6 filling Long glass fiber30 high toughness injection molding natural color sample availableMXD6 Plastic | Long Glass Fiber Reinforced MXD6 (MXD6-LGF) What is MXD6? Polyadipyl-m-benzoylamine, commonly referred to as MXD6 or nylon MXD6, is a high-performance engineering thermoplastic. Compared to other engineering plastics, MXD6 has higher mechanical strength and modulus. It is also a special high barrier nylon, with excellent resistance to oxygen and carbon dioxide. Unlike PVDC or EVOH, its barrier performance is not affected by temperature or humidity, making MXD6 ideal for high-temperature and humid conditions. Structural and Mechanical Performance MXD6 nylon exhibits high strength, high rigidity, high thermal deformation temperature, low thermal expansion, excellent dimensional stability, and low water absorption. Its mechanical properties change minimally after water absorption. MXD6 has low shrinkage for precision forming, excellent paintability at high temperatures, and outstanding barrier properties. Advantages of MXD6 Maintains high strength and rigidity over a wide temperature range High heat deflection temperature with low thermal expansion coefficient Low water absorption and minimal mechanical property reduction Small molding shrinkage, suitable for precision molding processes Excellent paintability, especially at high temperatures Outstanding barrier to oxygen, carbon dioxide, and other gases MXD6-LGF | Long Glass Fiber Reinforced MXD6 MXD6 can be compounded with long glass fibers, carbon fibers, minerals, and advanced fillers to produce composites with 50-60% glass fiber reinforcement. This results in exceptional strength and stiffness while maintaining a smooth, resin-rich surface ideal for painting, metal coating, or reflective housings. Key Advantages of MXD6-LGF High fluidity for thin walls: Can fill walls as thin as 0.5 mm even with 60% glass fiber content. Excellent surface finish: Resin-rich surfaces provide high gloss appearance despite high fiber content. Very high strength and stiffness: Comparable to many cast metals and alloys with 50-60% glass fiber. Good dimensional stability: Low shrinkage and tight tolerances; coefficient of linear expansion similar to many metals. MXD6-LGF TDS (Technical Data Sheet) Applications of MXD6-LGF MXD6-LGF replaces metals for high-quality structural parts in automotive, electronics, and electrical appliances. It performs well in environments requiring high mechanical strength and oil resistance, operating at 120–160℃ long-term. With glass fiber reinforcement, MXD6 maintains heat resistance up to 225℃, suitable for cylinder blocks, cylinder heads, pistons, and synchronous gears of automotive engines. MXD6/PPO alloys offer high temperature resistance, high strength, wear resistance, oil resistance, and excellent dimensional stability, enabling metal replacement in automotive body panels, fenders, wheel covers, and complex curved parts. About Us

- long glass fiber MXD6

- long fibre reinforced thermoplastics

- long glass fiber reinforced plastics granules

- MXD6 LGF

- MXD6 compounds

Tags :

-

LFT-G industry use HDPE filling LGF 30%-60% high toughness pellets 12mm sample freeHDPE Plastic | Long Glass Fiber Reinforced HDPE What is HDPE? High Density Polyethylene (HDPE) is a granular thermoplastic material that is non-toxic, odorless, and highly crystalline (80% - 90%). It has a softening point of 125–135°C and can be used at temperatures up to 100°C. Compared with Low-Density Polyethylene (LDPE), HDPE has superior hardness, tensile strength, creep resistance, wear resistance, electrical insulation, toughness, and cold resistance. It also offers excellent chemical stability, being insoluble in any organic solvents at room temperature and resistant to corrosion from acids, alkalis, and various salts. Long Glass Fiber Reinforced Plastics (LGF) Long glass fiber reinforced plastics (LGF plastics) are created by adding long glass fibers and other additives to pure plastics. This reinforcement significantly improves the material's mechanical and thermal properties, making it suitable for structural and engineering applications. LGF plastics are commonly used with materials such as PP, ABS, PA66, PA6, HDPE, PPA, TPU, PEEK, PBT, and PPS. Advantages of Long Glass Fiber Reinforced Plastics Increased heat resistance: Glass fibers improve the high-temperature performance of plastics, especially in nylon-based materials. Reduced shrinkage and increased rigidity: Fiber reinforcement restricts polymer chain movement, improving dimensional stability. Improved impact resistance: Reinforced plastics resist stress cracking and have higher toughness. Enhanced strength: Tensile, compression, and bending strength are significantly improved due to the high-strength glass fibers. Flame retardancy: Addition of fibers and additives reduces flammability, making most reinforced plastics non-ignitable. HDPE / LGF Datasheet Contact Us For more information about HDPE plastic and long glass fiber reinforced HDPE materials, please contact our sales team. We provide technical support, custom solutions, and sample requests for your industrial and engineering applications.

- HDPE filling long glass fiber white color

- high performance hdpe with lgf

- injection molded plastic hdpe virgin

- Original color 10-12mm hdpe pellets polymer resin

- engineering plastic can be recycled hdpe

- thermoplastic compounds hdpe high rigidity

Tags :

-

PPS Polyphenylene sulfide long glass fiber composite plasitc high toughessProduct number: PPS-NA-LGF Product color: Natural color Fiber specification: 20%-60% Product feature: 94-VO Flame retardant, High toughness, Low warpage, Fatigue resistance, Good appearance of product. Product application: Water heater impeller, Pump shell, Joint, Chemical pump impeller, Cooling water impeller, Home appliances parts.

- Low voltage switches

- High toughness

- Termoplastic material

- Original color

- Low warpage

- PPS resin

Tags :

-

Xiamen LFT-G ABS Acrylonitrile Butadiene Styrene long glass fiber reinforced for industrial useABS Plastic | Acrylonitrile Butadiene Styrene Engineering Thermoplastic ABS (Acrylonitrile Butadiene Styrene) is a widely used engineering thermoplastic known for its excellent impact resistance, mechanical strength, and processing versatility. ABS plastic is an amorphous polymer commonly used in automotive, electrical, consumer, and industrial applications. What Is ABS Plastic? ABS plastic is a thermoplastic polymer produced by polymerizing acrylonitrile, butadiene, and styrene. Each component contributes specific performance advantages: Acrylonitrile – chemical resistance and thermal stability Butadiene – toughness and impact resistance Styrene – rigidity, surface quality, and processability Due to this balanced structure, ABS engineering plastic offers high impact resistance, good dimensional stability, and easy processing, making it one of the most versatile thermoplastics on the market. ABS is non-toxic in solid form, provides good electrical insulation, and is widely accepted as a safe and reliable material for mass production. Main Advantages of ABS Plastic As a general-purpose engineering thermoplastic, ABS plastic offers the following key advantages: Excellent impact resistance and toughness Good mechanical strength with low weight Easy injection molding, extrusion, and machining Good surface finish and paintability Low electrical and thermal conductivity Cost-effective and widely available ABS can withstand repeated heating and cooling cycles, making it suitable for recyclable applications and long-term industrial use. ABS Plastic vs PLA: Material Comparison ABS and PLA are both popular thermoplastics, but they serve very different application requirements. ABS is a tougher and more durable engineering plastic, while PLA is primarily used for prototyping and hobbyist 3D printing. ABS vs PLA: Mechanical Strength ABS offers higher impact resistance and toughness than PLA PLA is stiffer but more brittle ABS vs PLA: Heat Resistance ABS softening temperature: ~105°C PLA softening temperature: ~60°C Due to its superior heat resistance, ABS is better suited for functional parts exposed to elevated temperatures. ABS vs PLA: Dimensional Stability & Accuracy PLA is easier to print and produces dimensionally stable parts during 3D printing. ABS, however, tends to warp during printing but performs better in real-world mechanical applications once molded. ABS vs PLA: Surface Finish Both materials show visible layer lines in FDM printing. ABS can be vapor-smoothed using solvents such as acetone, resulting in a smooth and glossy surface, while PLA typically requires sanding or coating. ABS vs PLA: Environmental Impact PLA is biodegradable under industrial composting conditions ABS is not biodegradable but is recyclable PLA degradation requires controlled industrial conditions and can take decades in natural environments. ABS offers long service life and durability for industrial products. ABS vs PLA: Cost Comparison Both ABS and PLA are low-cost thermoplastics. ABS may be slightly more expensive, but the difference is generally minimal and application-dependent. Typical Applications of ABS Plastic Thanks to its balance of toughness, processability, and cost efficiency, ABS engineering plastic is widely used in: Automotive interior and exterior components Electrical and electronic housings Consumer products and appliances Industrial enclosures and structural parts Injection molded and extruded components

- ABS can be recycled plastic made in China

- thermoplastic resin raw materials

- abs for whole sell good price fiberglass

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文