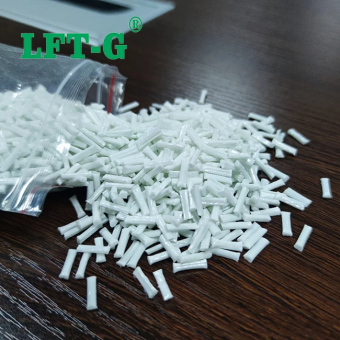

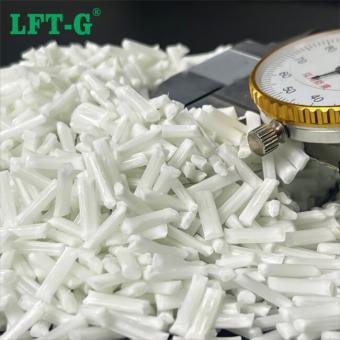

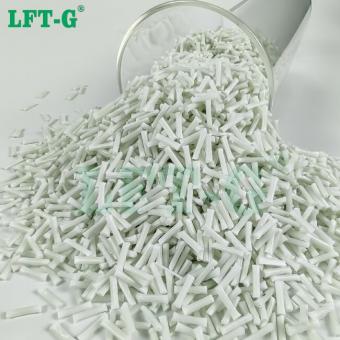

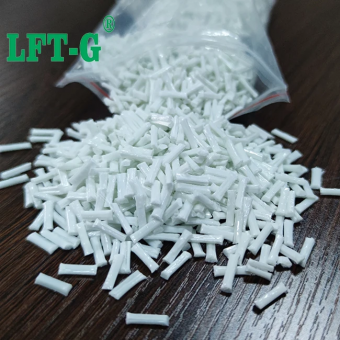

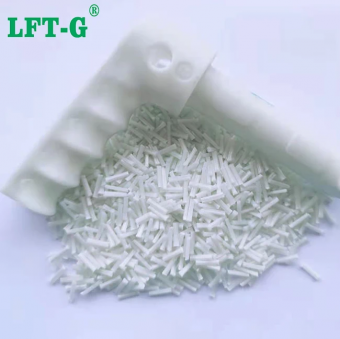

Long glass fiber has high strength, high rigidity, corrosion resistance, harsh environment suitability and low cost. When the resin matrix is impregnated and extruded into pellets ,Also called Long Glass Fiber Polymer it has good mechanical properties.

-

LFT-G fiber filled PBT composites high strength injection moldingOur long glass fiber reinforced PBT compounds offer high strength and excellent chemical compatibility, making them ideal for industrial applications where durability and performance are critical.

- chemical compatibility PBT

- long glass fiber filler polymer

- natural color pbt supplier

- PBT application reinforced materials

- compounds resin high strength

- Long fiber PBT for industrial use

Tags :

-

ProFiber Long Glass Fiber Reinforced PP – High-Performance Homopolymer for Injection MoldingOur Glass Fiber Reinforced Polymer with High-Performance offers exceptional strength and durability, perfect for injection molding PP applications.

- Glass Fiber Reinforced Polymer

- High-Performance PP Material

- Injection Molding PP

- Copolymer Plastic Material

- Reinforced Thermoplastic

- Durable Plastic for Automotive

Tags :

-

LFT PPA Long Glass Fiber Reinforced Polymer for Durable ApplicationsPPA long glass fiber composites are high-performance thermoplastic materials that combine the durability and strength of glass fiber reinforcement with the superior properties of PPA engineering plastics, making them ideal for demanding industrial applications.

- PPA long glass fiber composite

- high-performance PPA polymer

- glass fiber reinforced thermoplastics

- PPA engineering plastic materials

- durable thermoplastic composites

- industrial PPA reinforced polymer

Tags :

-

High Strength ABS Resin Long Glass Fiber filled PelletsABS long glass fiber reinforced modified materials are engineering plastics with high strength, excellent impact toughness, and heat resistance, widely used in industries such as automotive, electronics, and home appliances. The reinforcement of long glass fibers enhances the material's rigidity and fatigue resistance. It is suitable for industrial products requiring high strength and performance.

- glass fiber reinforced abs

- abs glass fiber compound

- abs granules manufacturer

- natural abs color

- LFT advanced materials

- Acrylonitrile Butadiene Styrene

Tags :

-

High tensile strength TPU resin Long Glass Fiber filled PelletsTPU long glass fiber composite features high strength, toughness, and wear resistance, making it ideal for power tools, automotive parts, and sports equipment. It offers excellent impact resistance, dimensional stability, and a lightweight alternative to metal.

- tpu plastic pellets

- tpu composite fabric

- tpu automotive industry

- tpu pellets for injection molding

- tpu toe cap

- China TPU factory

Tags :

-

China LFT High Toughness MXD6 Composite filling Long Glass Fiber Original ColorNylon - MXD6 is a kind of crystalline polyamide resin, which is synthesized by the condensation of m-benzoylamine and adipic acid.

- Crystalline nylon resin mxd6 gf good price

- Composite materials with long glass fiber mxd6

- Higher performance plastic mxd6

- Made in China products compounds mxd6

- Customized plastic fiber glass add high sstrength mxd6

- Thermoplastic resin thermoplastic resin

Tags :

-

LFT Long Glass Fiber Reinforced High Density Polyethylene for Industrial UseHigh-density polyethylene (HDPE), also called polyethylene high-density (PEHD), is a thermoplastic polymer made from the monomer ethylene. When used for HDPE pipes, it is sometimes called "alkathene" or "polythene." With a high strength-to-density ratio, High-density polyethylene (HDPE) is used to produce corrosion-resistant piping. In addition, HDPE is commonly recycled.

- hdpe glass

- fiber reinforced hdpe composite pipe

- lft pellets

- long glass fiber

- long fiber compounds

- long fiber thermoplastic composites

Tags :

-

LFT Long Glass Fiber Reinforced PLA Compounds Injection MoldingPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- wholesale glass fiber reinforced plastic resin dispenser in china

- pla price per kg

- thermoplastic resin suppliers

- reinforced pla

- polylactic acid (pla) plastic

- pla pellets

Tags :

-

LFT Long Glass Fiber Reinforced PBT Compounds Injection MoldingPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- High-Performance PBT Materials

- PBT Composite Materials for Industrial Applications

- PBT Thermoplastic for High-Temperature Parts

- PBT Long Glass Fiber for Manufacturing

- High-Strength PBT Long Fiber Composites

- Sustainable PBT Thermoplastics

Tags :

-

LFT Long Glass Fiber Reinforced PPA Compounds Special NylonPolyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

- PPA Materials for Aerospace Applications

- PPA Composites for Automotive Parts

- OEM PPA Composite Materials

- PPA for Electrical Components and Devices

- PPA Reinforced Plastic for Structural Applications

- PPA Reinforced Thermoplastic

Tags :

-

LFT Long Fiber Reinforced Polyphenylene Sulfide Compounds Flame RetardantLFT®PPS-NA-LGF is glass reinforced PPS compound, which is filled with glass fiber based on the PPS resin. The characteristic of PPS compounds includes good mechanical properties, high rigidity, high creep resistance, high temperature resistance, flame resistance, chemical resistance, excellent electrical insulation properties, arc resistance, low water absorption, low mold shrinkage, easy processing, good dimensional stability, and radiation resistance.

- PPS Long Fiber Composite

- PPS Glass Fiber for Industrial Use

- PPS High Strength Materials

- PPS Thermoplastic for High-Temperature

- Long Glass Fiber Reinforced PPS

- Polyphenylene Sulfide High Performance Plastics

Tags :

-

LFT Long Fiber Reinforced Nylon 12 High Performance CompoundsPA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties. If you’re considering converting metal parts to plastic, PA12 will be a good choice.

- High Performance PA12 Materials

- Lightweight PA12 Glass Fiber Composite

- Advanced PA12 Long Fiber Materials for Manufacturing

- PA12 Fiber Reinforced Thermoplastics

- PA12 Composite Materials for Electronics

- PA12 Composite Materials Supplier

Tags :

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文