new blog

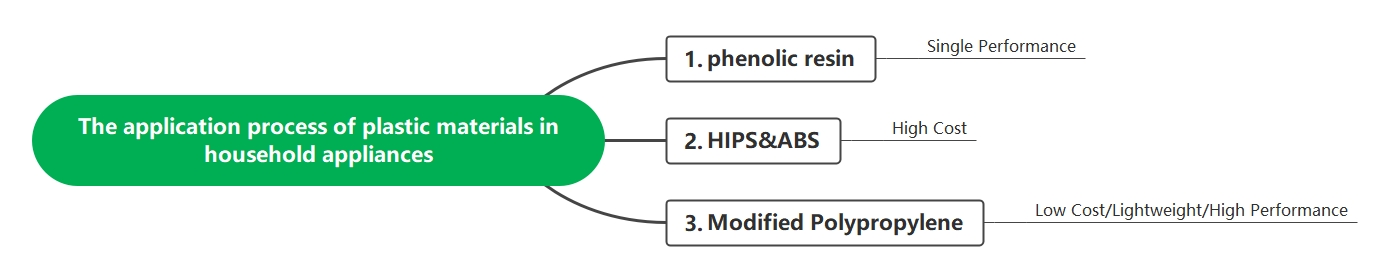

HIPS and ABS are the first plastic materials used in household appliances, due to the high price of HIPS and ABS resin, the market has gradually developed PP(polypropylene) modified materials suitable for household appliance parts, and partially replaced HIPS and ABS resin in household appliance products with its advantages of low cost, light weight and good performance.

Now the modified PP plastic material has become the mainstay of the home appliance industry. With its unique advantages, it has been widely used in various household appliances such as washing machines, refrigerators and air conditioners. All this is inseparable from the continuous breakthrough and innovation of science and technology over the years.

Polypropylene Plastic Characteristic

| Advantages | Defects |

| High comprehensive performance | Low stiffiness and strength |

|

Good chemical resistance |

Low impact strength under low temperature |

| Easy to process | Large molding shrinkage |

| Good price | Low anti-aging performance |

Therefore, it must be modified to meet the performance requirements of home appliances.

Modified propylene kinds

1) Minerals reinforced grade

2) Weather resistant grade

3) Flame retardant grade

4) Glass fiber reinforced grade

5) Antibacterial grade

1) Minerals reinforced grade

| Filler |

Calcium carbonate, talc powder, wollastonite, glass beads, mica powder and other minerals |

| Modification |

Improve the mechanical properties and impact toughness of polypropylene, reduce the molding shrinkage of polypropylene to strengthen its dimensional stability |

| Cost |

Significantly reduce the cost of polypropylene |

| Applications |

Washing machine, microwave oven, speaker, refrigerator, rice cooker, sanitary ware, baby carriage accessories, car bumper, car interior accessories |

The inner bucket of the washing machine was originally made of stainless steel, and in the 1990s, the United States BASELL Company and the South Korean Samsung Company began to study "using modified PP to replace stainless steel to make the inner bucket of the drum washing machine" and realized commercialization.

Since then, washing machine companies began to use a large number of such modifiers. The mineral content of this material is as high as 40%, its tensile strength is 33MPa, the elongation at break can reach more than 90%, and the notched impact strength is about 10kJ/m2.

2) Weather resistant grade

Because polypropylene contains unstable tertiary carbon groups, and tertiary carbon atoms are very sensitive to ultraviolet light, it is easy to oxidize, resulting in poor oxidation resistance and radiation resistance of polypropylene.

After the action of light, heat and oxygen, it is easy to age and degrade, resulting in discoloration and strength decline, which limits its application in outdoor products.

The purpose of weather-resistant modification: it can greatly improve the service life of PP material in harsh outdoor weather conditions.

(Air conditioner outdoor unit axial flow blades)

The modified material is mainly used in the manufacture of household appliances used in the open air all the year round, especially for the manufacture of air conditioner outdoor host shell to replace the traditional metal spray shell. Air conditioner outdoor unit shell to withstand the sun, rain, cold and other different climatic conditions of the test, and to meet the long-term use requirements.

3) Flame retardant grade

Flame retardant modified PP - refers to the modified PP plastic with flame retardant properties.

Through flame retardant modification, PP products can reach the UL94V-0 level, and can withstand 650℃ or even 850℃ hot wire without burning.

This flame-retardant modified PP material is commonly used in the production of components with potential combustion hazards, such as TV housings, washing machine control panels, remote control housings, aquarium evaporation trays, ventilation ducts, lighting fixtures, automotive parts, electronic components, profiles, sheets, wire sleeves, etc.

4) Glass fiber reinforced grade

Reinforcement modification - Fibrous materials with large diameter to thickness ratio are added to plastics, which can significantly improve the tensile strength and bending modulus (rigidity) of plastic materials.

High mechanical strength, heat resistance, high impact resistance, high flow, water vapor resistance, chemical corrosion resistance, good creep resistance, can be used as engineering plastics.

| Applications | Advantages |

| Air conditioning, refrigerator and other refrigeration equipment | Lower cost than modified ABS plastic |

| Washing machine | High mechanical properties |

|

Rice cooker, microwave oven |

High temperature resistance |

5) Antibacterial grade

Modified Polypropylene Trends

High hardness, high gloss PP

Such products may replace some household appliances, especially PS and ABS for small household appliances.

Halogen-free flame retardant PP

With the implementation of the EU RoHS Directive, countries attach great importance to environmental protection, the choice of halogen-free flame retardant PP materials is to choose a safe, environmentally friendly, efficient and sustainable future. The market prospect is broad.

Long glass fiber reinforced PP

Ordinary glass staple fiber reinforced PP, the glass fiber contains short, easy to warpage, low impact strength, easy to deformation when heated, therefore, long glass fiber can overcome the shortcomings of the above short glass fiber and product surface. It has good temperature, high impact strength and high heat resistance, and can be used in refrigerators and kitchen utensils.

Antibacterial PP

This plastic is a new functional polymer material with bactericidal and antibacterial properties, which is used in the plastic parts of the inner liner of washing machines and electric water tanks, and has broad prospects.

Contact us for more information about Polypropylene Plastic

Xiamen LFT Composite Plastic Co., Ltd. (Click to enter the website)

Ms. Wallis

Email: sale02@lfrtplastic.com

Whatsapp: +86 13950095727