new blog

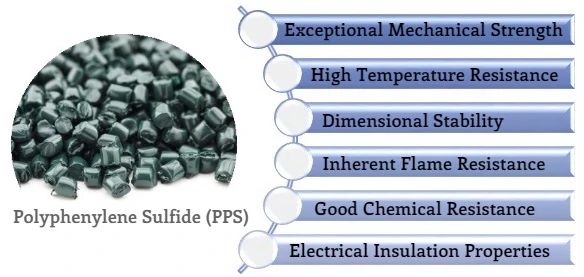

Polyphenylene sulfide (PPS) is a high performance high temperature resistant engineering thermoplastic. It has a semi-crystalline structure and a unique combination of properties. They range from dimensional and thermal stability to high temperature and chemical resistance. Due to its excellent electrical insulation properties, it is suitable for electrical components. Learn more about this versatile material.

What is Polyphenylene Sulfide (PPS)?

Polyphenylene sulfide (PPS) is a semi-crystalline high temperature engineering thermoplastic. It is a rigid and opaque polymer. It has a high melting point (280°C). It consists of p-phenylene units alternating with thioether bonds.

PPS has an excellent balance of properties such as:

*Excellent mechanical strength

*Dimensional stability

*Electrical insulation properties

*Resistance to fire, chemicals and high temperatures

Easy processing due to its increased toughness at high temperatures. These properties make it an alternative to metals and thermosets. Suitable for automotive parts, appliances, electronics and many other applications.

How is PPS made?

The first commercial process for PPS was developed under the Ryton brand name by Edmonds and Hill (U.S. Patent 3,354,129, 1967) while working at Philips Petroleum. In the original process developed by Philips, the resulting product had a low molecular weight. It can be used in this form for coating applications.

To produce molded grades, PPS is cured (chain expansion or cross-linking) near the melting point of the polymer in the presence of a small amount of air. This curing process results in:

* Increase in molecular weight

*Increase in toughness

*Loss of solubility

*Decreased melt fluidity

*Decreased crystallinity

*Darkened color (brownish, off-white compared to this linear PPS grade)

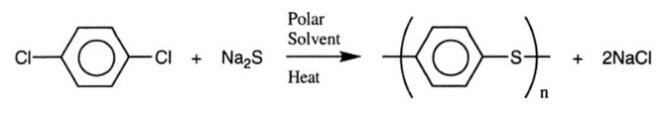

PPS is produced by the reaction of sodium sulfide and dichlorobenzene in a polar solvent (e.g., N-methylpyrrolidone) at elevated temperatures [about 480°F (250°C)].

What are the properties of polyphenylene sulfide (PPS)?

*Crystal structure and physical properties: PPS is a semi-crystalline polymer.

*Dimensional Stability: PPS is ideal for producing complex parts with very tight tolerances. The polymer exhibits excellent dimensional stability even when used at high temperatures and high humidity.

*Electrical Properties: PPS has excellent electrical insulation properties. It maintains high volume resistivity and insulation resistance after exposure to high humidity. It has a less pronounced O 2 sensitivity. It can be easily doped to obtain high electrical conductivity.

*Thermal Properties and Fire Resistance: PPS is a high temperature specialty polymer. Most PPS compounds pass UL94V-0 without the addition of flame retardants.PPS can withstand 260°C for short periods of time and can be used for long periods of time up to 200°C. PPS can also be used as a fire retardant at high temperatures.

*Mechanical Properties: PPS has high strength, high stiffness and low degradation properties even at high temperatures. It also exhibits excellent fatigue durability and creep resistance.PPS has a lower elongation at break, is more costly and brittle. Today, PPS is available in different forms and grades such as compounds, fibers, filaments, films and coatings.

*Chemical properties: PPS has good chemical resistance. If cured, it is unaffected by alcohols, ketones, chlorinated aliphatic compounds, esters, liquid ammonia, and others. It is also susceptible to dilute hydrochloric acid, nitric acid and concentrated sulfuric acid. It is insensitive to moisture and has good weather resistance.

How do additives optimize PPS performance?

A large number of PPS compounds are available on the market. Due to the chemical stability of the polymers, a wide range of fillers and reinforcing fibers, as well as combinations thereof, can be applied.PPS resins are generally reinforced with a variety of reinforcements or blended with other thermoplastics to further improve their mechanical and thermal properties.PPS is mostly filled with glass fibers, carbon fibers, and PTFE.

Many grades are available, including:

*Unfilled natural color

*20%-60% glass filled

*Glass mineral filled

*Conductive and antistatic grades

*Flame retardant grades

*High temperature resistant grade

*Toughened grades

Typically pure polymer grades are used for fibers and films. Whereas filled/reinforced grades are used in thermally and/or chemically demanding environments.

What are the processing conditions for PPS?

PPS resins (base polymers, glass reinforced and mineral/glass reinforced systems) are commonly used for:

*Injection molding.

* Extrusion applications.

They can be processed at temperatures in the 300 to 350°C range. Processing of PPS is sometimes hindered by its high melting point.

For filled PPS grades, higher processing temperatures should be used to avoid barrel, screw and screw tip wear.

Pre-drying: 150-160°C for 2-3 hours or 120°C for 5 hours. It enhances the appearance of the molded product and prevents drooling. Pre-drying is particularly important for carbon fiber filled grades. This is due to the high hygroscopicity of carbon fibers.

Injection Molding: For higher productivity, the mold temperature can be set to 50°C and post-crystallization at 200°C. This is not recommended for products requiring high dimensional stability. However, this is not recommended for applications requiring high dimensional stability.

Due to its low viscosity, the sealing of the mold must be checked!

Cylinder temperature: 300-320°C

Mould temperature: 120-160°C to obtain good crystallization and minimize warpage

Injection pressure: 40-70 MPa

Screw speed: 40-100 rpm

Extrusion: Typically used for fibers and monofilaments as well as tubes, rods and slabs.

Drying conditions: 121°C for 3 hours

Mold temperature: 300-310°C

Melt temperature: 290-325°C

Is PPS recyclable?

Polyphenylene sulfide (PPS) is recyclable.PPS can be recycled in the following ways:

*Mechanical recycling methods such as grinding or shredding

*Chemical recycling methods, such as depolymerization

Due to its high melting point and chemical resistance, the recycling process for PPS can be challenging. This in turn makes disposal more difficult. However, there are specialized recycling facilities to handle PPS recycling and efforts are underway to improve its recyclability and promote a circular economy.

Is PPS toxic?

Polyphenylene sulfide (PPS) is generally considered a safe and non-toxic material. PPS may pose a risk to human health and the environment if not handled or used properly. Therefore, it is important to follow proper safety protocols and guidelines.

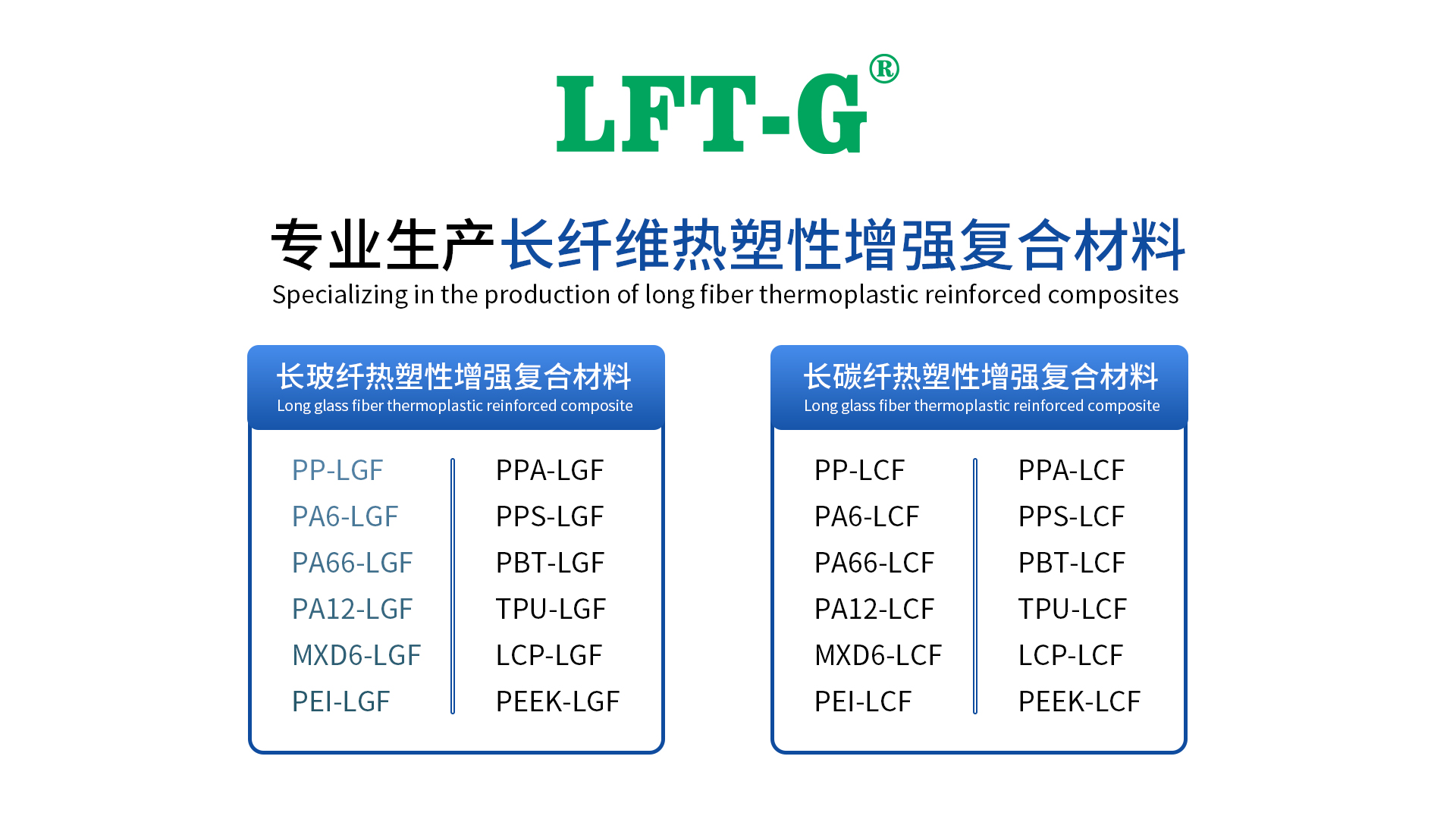

Who we are?

Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.