-

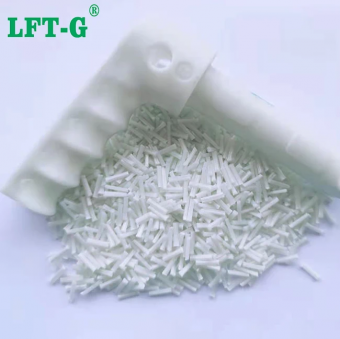

Xiamen LFT Thermoplastic Polyurethane (TPU) Long Glass Fiber Reinforced Thermoplastic CompoundsThermoplastic Polyurethane is soft and elastic, with excellent tensile and tear strength. For this reason, it is often used to make parts that demand a rubber-like elasticity. TPU is a little bit expensive than other resins, but there is no substitute for many applications, such as protective wire and cable sheaths. Another advantage is that TPU improves the grip for products that need to be held securely in hand. About TPU-LGF compounds What Products Are Best Manufactured via Thermoplastic Polyurethane (TPU)? Some of the TPU products manufactured are automotive instrument panels, caster wheels, sporting goods, power tools, drive belts, medical devices, footwear and etc. What is Thermoplastic Polyurethane (TPU) for Plastic Injection Molding? ETPU is a tough, highly abrasion-resistant resin that bridges the gap between rubbers and plastics. TPUs can be formulated to be rigid or elastomeric. TPU exhibits a high flex before break and is ideal for wheels and door panels. What is the Molding Temperature for Thermoplastic Polyurethane (TPU)? depending on the TPU being molded. Materials Details Number TPU-NA-LGF Color Natural color or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead time 2-15 days Port of Loading Xiamen Port Trade terms EXW/FOB/CFR/CIF/DDU/DDP About Xiamen LFT Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & developmen (R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc. LFT long fiber reinforced thermoplastic engineering materials,compared to ordinary short fiber reinforced thermoplastic materials (fiber length is less than 1-2 mm), the LFT process produces thermoplastic engineering material's fibers in lengths of 5-25 mm. The long fibers are impregnated with the resin through a special mold system to obtain long strips that are fully impregnated with the resin ,and then cut to the length as required. The most used base resin is PP, by PA6, PA66, PPA,PA12,MXD6,PBT,TPU,PPS, ABS,PEEK, etc. Conventional fibers include glass fiber, carbon fiber. Depending on the end use, the finished products can be used for injection molding,extrusion, molding, etc., or directly used for plastic instead of steel and thermoset products.

- High performance thermoplastic engineering plastics

- excellent heat resistance with filler

- injection molding products light weight

- excellent tensile and tear strength

- modified plastic manufacturer can be customized

- can be recylced GFRP GF30

Tags :

-

LFT high strength Polylactic Acid PLA Long Glass Fiber reinforced PelletsPLA is often regarded as being biodegradable.

- Long Glass Fiber Reinforced PLA Properties

- PLA with Long Glass Fiber Strength and Durability

- Long Glass Fiber PLA Composites Applications

- High Performance Long Glass Fiber PLA Materials

- Long Glass Fiber PLA vs. Short Fiber PLA

- Long Glass Fiber PLA Manufacturing Process

Tags :

-

LFT Long Fiber Reinforced Nylon 12 High Performance CompoundsPA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture. PA 12 has long been used by injection molders due to these mechanical properties. If you’re considering converting metal parts to plastic, PA12 will be a good choice.

- High Performance PA12 Materials

- Lightweight PA12 Glass Fiber Composite

- Advanced PA12 Long Fiber Materials for Manufacturing

- PA12 Fiber Reinforced Thermoplastics

- PA12 Composite Materials for Electronics

- PA12 Composite Materials Supplier

Tags :

-

LFT Long Fiber Reinforced Polyphenylene Sulfide Compounds Flame RetardantLFT®PPS-NA-LGF is glass reinforced PPS compound, which is filled with glass fiber based on the PPS resin. The characteristic of PPS compounds includes good mechanical properties, high rigidity, high creep resistance, high temperature resistance, flame resistance, chemical resistance, excellent electrical insulation properties, arc resistance, low water absorption, low mold shrinkage, easy processing, good dimensional stability, and radiation resistance.

- PPS Long Fiber Composite

- PPS Glass Fiber for Industrial Use

- PPS High Strength Materials

- PPS Thermoplastic for High-Temperature

- Long Glass Fiber Reinforced PPS

- Polyphenylene Sulfide High Performance Plastics

Tags :

-

Engineering-Grade MXD6 LFT Material for Automotive & ElectronicsMXD6 Nylon - MXD6 is a kind of crystalline polyamide resin, which is synthesized by the condensation of m-benzoylamine and adipic acid. The advantages of nylon MXD6 1. In a wide range of temperature, maintain high strength, high rigidity 2. High thermal deformation temperature and small thermal expansion coefficient 3. Low water absorption rate, small size change after water absorption, less mechanical strength reduction 4. Forming shrinkage rate is very small, suitable for precision forming processing 5. Excellent coating, especially suitable for high temperature surface coating 6. Oxygen, carbon dioxide and other gases also have excellent barrier Application of MXD6 in plastic modification industry MXD6 can be combined with fiberglass, carbon fiber, mineral, and/or advanced fillers for use in fiberglass reinforced materials containing 50-60% and for exceptional strength and stiffness. Even when filled with high glass content, its smooth, resin-rich surface produces a fibre-free high gloss surface, ideal for painting, metal-plating, or creating naturally reflective shells. 1. suitable for high liquidity of thin wall It is a very fluid resin that can easily fill thin walls as thin as 0.5 mm thick even when the glass fiber content is as high as 60%. 2. Excellent surface finish A resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content. 3. High strength and stiffness The tensile and flexural strength of MXD6 is similar to that of many cast metals and alloys with the addition of 50-60% glass fiber reinforced material. 4. good dimensional stability At ambient temperatures, the linear expansion coefficient (CLTE) of MXD6 glass fiber composites is similar to that of many cast metals and alloys. Strong reproducibility due to low shrinkage and the ability to maintain tight tolerances (length tolerances as low as ± 0.05% if properly formed). Datasheet Tested by our own lab, for reference only. laboratory & Warehouse Frequently asked questions 1. How to choose the fiber content of the product? Is the larger product suitable for higher fiber content material? A. This is not absolute. The content of glass fiber is not more is better. The suitable content is just to meet the requirements of each products. 2. Can products with appearance requirements be made of long-fiber materials? A. The main feature of LFT-G thermoplastic long glass fiber and long carbon fiber is to show the mechanical properties. If the customer has bright or other requirements for the appearance of the products, it needs to be evaluated in combination with specific products. 3. Are there any special process requirements of long carbon fiber injection molding products? A. We must consider the requirements of long fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long fiber is a relatively high cost materiaql, and need to evaluate the cost performance problem in the selection process. Main materials Why choose us 1. Integration of R&D, production and sales 2. Customized products, one-to-one pre-sales and after-sales service 3. Passed a number of system certifications, and product quality is stable 4. Five warehousing centers nationwide to meet customers' high-volume needs 5. Testing is available in an independent laboratory with technical experts with 30 years of experience 6. Sold globally to Asia, Europe, North America, Middle East

- high performance MXD6

- MXD6 composite for drone frames

- MXD6 replacement for metal

- long fiber reinforced thermoplastics

- high stiffness thermoplastics for UAV

- China MXD6 long glass fiber supplier

Tags :

-

Xiamen LFT-G Polypropylene filling long glass fiber high performance modified plastic 12mmPP-LGF Glass fiber reinforced PP, usually, the tensile strength of PP material is between 20M~30MPa, bending strength is between 25M~50MPa, bending modulus is between 800M~1500MPa. If PP is to be used in engineering structural parts, it must be reinforced with glass fiber. Glass fiber reinforced PP, through glass fiber reinforced PP product mechanical properties can be multiplied or even several times the improvement. Specifically, the tensile strength reaches 65MPa~90MPa, the bending strength reaches 70MPa~120MPa, and the bending modulus reaches 3000MPa~4500MPa. Such mechanical strength can be completely comparable with ABS and enhanced ABS products, and it is more heat resistant. Glass fiber reinforced PP, general ABS and reinforced ABS heat resistance temperature between 80℃~98℃, and glass fiber reinforced PP material heat resistance temperature can reach 135℃~145℃. PP filling modification, adding a certain amount of inorganic minerals in PP, such as talcum powder, calcium carbonate, titanium dioxide, mica, etc., can improve rigidity, improve heat resistance and luster; Filling carbon fiber, boron fiber, glass fiber can improve the tensile strength; Adding flame retardant can improve flame retardant property. Filling antistatic agent, colorant, dispersant, etc. can improve the antistatic property, colorability and fluidity, etc.; Filling nucleating agent can speed up the crystallization speed, increase the crystallization temperature, form more and smaller spherical crystals, thus improving the transparency and impact strength. Therefore, the filler has a significant effect on improving the performance of plastic products, improving the plastic molding processability and reducing the cost. Application As one of the four general plastic materials, PP has excellent comprehensive performance, good chemical stability, better molding performance and relatively low price; But it also has the strength, modulus, hardness is low, low temperature impact resistance strength is poor, forming shrinkage, easy aging and other shortcomings. Therefore, it must be modified so that it can adapt to the demand of the product. The modification of PP material is generally through adding mineral reinforcement toughening, weather resistance modification, glass fiber reinforcement, flame retardant modification and super toughness modification, and each kind of modified PP has a large number of applications in the field of household appliances. Glass fiber reinforced PP, can be used to make refrigerators, air conditioning refrigeration machines such as axial flow fans and cross flow fans. In addition, it can also be used to manufacture the inner drum of high speed washing machine, wave wheel, belt wheel to adapt to its high requirements on mechanical properties, for the rice cooker base and handle, electronic microwave oven and other places with high requirements on temperature resistance. Glass fiber reinforced PP. Ordinary short glass fiber reinforced PP, because the glass fiber contains short, easy warping, low impact strength, easy deformation when heated, long glass fiber can overcome the above defects of short glass fiber, and the product has a better surface, higher temperature, higher impact strength, can be used in refrigerators and kitchen appliances with high heat resistance. Glass fiber reinforced PP is on the basis of the original pure PP, adding glass fiber and other additives, so as to improve the scope of use of materials. Generally speaking, most glass fiber reinforced materials are used in the structural parts of the product, which is a kind of structural engineering materials. Datasheet Cases Xiamen LFT composite plastic Co., Ltd. Xiamen LFT Composite Plastic Co.,LTD was established in 2009, is a brand-name global suppliers of long fiber reinforced thermoplastic materials integrating product research & development(R&D), production and sale marketing. Our LFT products have passed the ISO9001&16949 system certification and have obtained lots of national trademarks and patents, covering the fields of automotive, military parts and firearms, aerospace, new energy, medical equipment, power wind energy, sports equipment, etc.

- long glass fiber polypropylene high performance

- pp injection molding composite

- PP resin compounds LFT GF

- pp lgf lft thermoplastic resin made in China

- lgf filling pp raw materials sample available

- pp industry use lft green materials

Tags :

-

LFT-G industry use HDPE filling LGF 30%-60% high toughness pellets 12mm sample freeHDPE Plastic | Long Glass Fiber Reinforced HDPE What is HDPE? High Density Polyethylene (HDPE) is a granular thermoplastic material that is non-toxic, odorless, and highly crystalline (80% - 90%). It has a softening point of 125–135°C and can be used at temperatures up to 100°C. Compared with Low-Density Polyethylene (LDPE), HDPE has superior hardness, tensile strength, creep resistance, wear resistance, electrical insulation, toughness, and cold resistance. It also offers excellent chemical stability, being insoluble in any organic solvents at room temperature and resistant to corrosion from acids, alkalis, and various salts. Long Glass Fiber Reinforced Plastics (LGF) Long glass fiber reinforced plastics (LGF plastics) are created by adding long glass fibers and other additives to pure plastics. This reinforcement significantly improves the material's mechanical and thermal properties, making it suitable for structural and engineering applications. LGF plastics are commonly used with materials such as PP, ABS, PA66, PA6, HDPE, PPA, TPU, PEEK, PBT, and PPS. Advantages of Long Glass Fiber Reinforced Plastics Increased heat resistance: Glass fibers improve the high-temperature performance of plastics, especially in nylon-based materials. Reduced shrinkage and increased rigidity: Fiber reinforcement restricts polymer chain movement, improving dimensional stability. Improved impact resistance: Reinforced plastics resist stress cracking and have higher toughness. Enhanced strength: Tensile, compression, and bending strength are significantly improved due to the high-strength glass fibers. Flame retardancy: Addition of fibers and additives reduces flammability, making most reinforced plastics non-ignitable. HDPE / LGF Datasheet Contact Us For more information about HDPE plastic and long glass fiber reinforced HDPE materials, please contact our sales team. We provide technical support, custom solutions, and sample requests for your industrial and engineering applications.

- HDPE filling long glass fiber white color

- high performance hdpe with lgf

- injection molded plastic hdpe virgin

- Original color 10-12mm hdpe pellets polymer resin

- engineering plastic can be recycled hdpe

- thermoplastic compounds hdpe high rigidity

Tags :

-

LFT Polyphenyl Sulfide PPS Long Carbon Fiber Reinforced flame retardantPolyphenylene sulfide is a new functional engineering plastic.

- Polyphenyl sulfide long carbon fibre

- PPS plastic rein forced compounds

- Composite material pps industrial use

- Filling lcf 30 pps composite plastic new materials

- High flame retardant car parts

- Factory use raw material modified plastic high performance

Tags :

-

Xiamen LFT ABS (Acrylonitrile Butadiene Styrene) Long Glass Fiber Reinforced Thermoplastic CompoundsABS-LGF (Glass Fiber Reinforced ABS) Overview ABS is a versatile engineering plastic known for chemical and thermal stability, strength, toughness, and glossy finish. It is widely used in consumer products such as toys and helmets, as well as automotive applications like interior trim, housings for electronics, and more. Reinforcing ABS with glass fiber significantly improves rigidity, heat resistance, and dimensional stability. ABS-LGF composites provide excellent cost-performance balance, helping manufacturers reduce costs while meeting production needs. About ABS-LGF Compounds Applications of Modified ABS 1. Automotive Parts: Instrument panels, fenders, interiors, lights, mirrors, audio systems. 2. Electronic & Electrical Components: IT and OA equipment shells, converters, power sockets. 3. Electronic Appliances: Switches, controllers, monitors, housings, brackets. 4. Home Appliances: Electrical components, control boxes. Advantages of ABS Injection Molding High Productivity: Efficient, low-waste process ideal for high-volume manufacturing. Complex Part Design: Capable of multi-featured components, including overmolding and metal inserts. Increased Strength: ABS provides excellent mechanical strength and durability. Flexible Color & Material Options: Easily colored, painted, or electroplated to improve environmental resistance. Decreased Waste: Low-wastage production, limited to sprue, runners, and flashing. Low Labor Cost: Highly automated process reduces human intervention and lowers cost per part. Material Details Number ABS-NA-LGF Color Natural or Customized Length 6-25 mm Package 25kg/bag MOQ 25kg Lead Time 2-15 days Port of Loading Xiamen Port Trade Terms EXW / FOB / CFR / CIF / DDU / DDP About Xiamen LFT Founded in 2009, Xiamen LFT Composite Plastics Co., Ltd. is a leading global supplier of long fiber reinforced thermoplastic materials, integrating R&D, production, and marketing. Our products are ISO9001 & IATF16949 certified, patented, and applied in automotive, aerospace, medical, new energy, military, sports equipment, and more. Compared to short fiber thermoplastics (1-2 mm fibers), our LFT materials (5-25 mm fibers) are fully impregnated with resin, ensuring superior mechanical performance. Base resins include PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Conventional fibers include glass and carbon fibers. Finished products can be used for injection molding, extrusion, or directly replace steel and thermoset components.view more

e-mail

e-mail English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文